HIGH PRESSURE CONTROL VALVE

Installation, Operation & Maintenance Guide

7

www.kimray.com

Model: PO, PC

1 Installation

Before installing the control valve, inspect it for shipment

damage and for foreign material that may have collected during

shipment. Inspect the openings in the valve and clean the pipe

lines to remove scale, chips and debris.

1. Install the valve with the arrow on the body pointing in the

direction of flow. The arrow indicates that the direction of flow

and will not necessarily prevent flow in the opposite direction.

The flow direction of the HPCV PB is up through

the valve. The stem guided trim is down through

the valve. If conditions indicate the possibility of

back word flow, you may wish to install check valves.

2. Install the valve using good piping practice. For flanged

bodies use a suitable gasket between the body and the pipeline

flanges. For threaded (NPT) bodies, use TFE Tape or pipe

thread sealant on external pipe threads.

3. Connect instrument gas to the actuator connection. The

maximum required instrument gas pressure is 30 psig (2 bar);

45 psig (3 bar) is permissible.

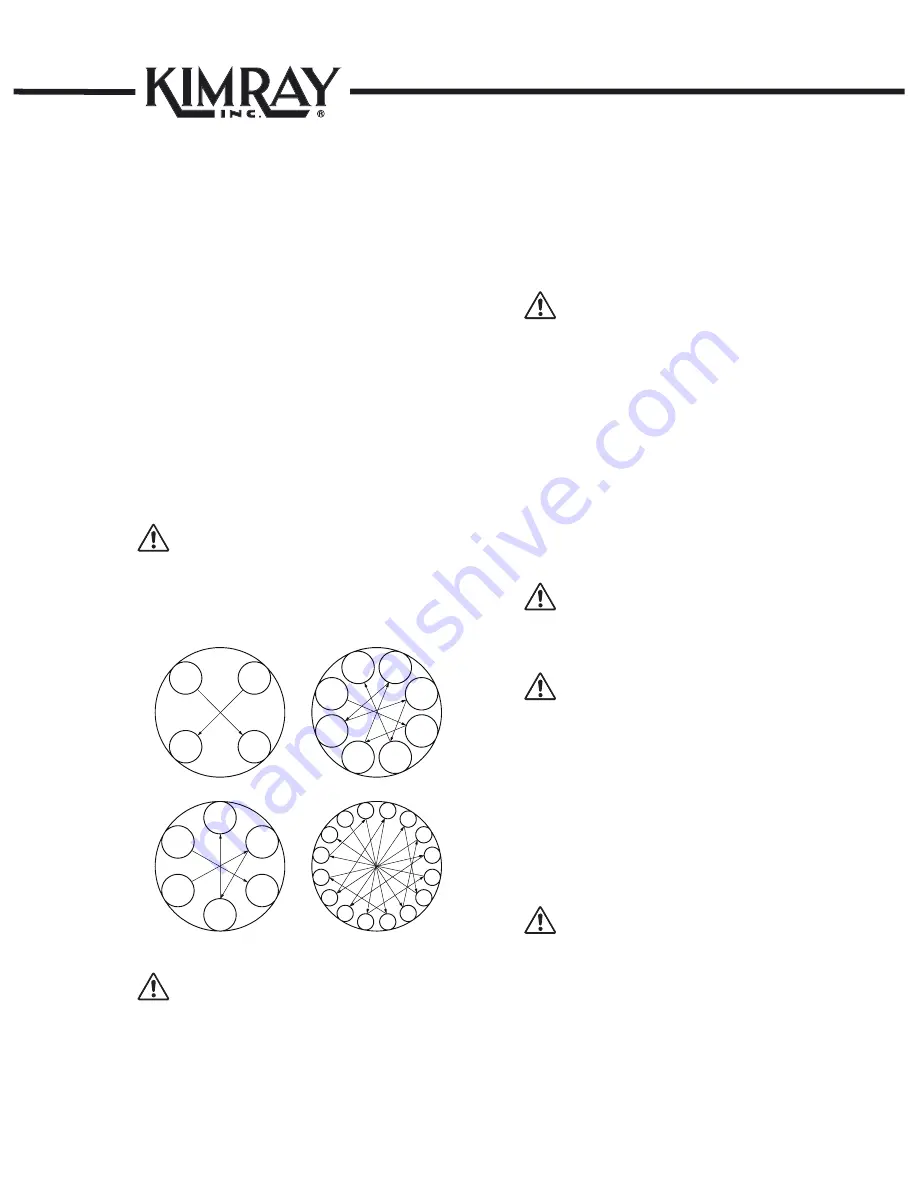

NOTE:

Always check fastener tightness prior to valve installation,

testing, and use, as fasteners have the potential to loosen

in transit. This is recommended to ensure your safety and

proper valve function.

*Kimray assembly torque method below*

Four Bolt

Four Bolt

11

22

33

44

Six Bolt

Six Bolt

11

22

33

44

55

66

Eight Bolt

Eight Bolt

11

22

33

44

55

88

66

77

Sixteen Bolt

Sixteen Bolt

11

22

99

14

14

55

16

16

88

11

11

44

13

13

10

10

66

15

15

77

12

12

33

CAUTION:

When ordered, the high pressure valve configuration and

construction materials were selected to meet specific pressure,

temperature, pressure drop and fluid conditions. Since

some body/trim material combinations are limited in their

pressure drop and temperature ranges, DO NOT subject

the high pressure valve to any other conditions without first

contacting the Kimray Inc, sales office or a sales/applications

representative.

2

Start-up and Test

With the installation completed and appropriate relief and

check valves installed and set, slowly open the upstream and

downstream shutoff valves. In order to test the function of

the valve, allow only a small amount of upstream fluid to flow

through the upstream shutoff valve. Check for proper valve

operation by cycling the actuator arm several times.

WARNING:

DO NOT exceed the maximum supply pressure specified on the

HPCV nameplate. Under no circumstances should the HPCV

supply pressure ever exceed the maximum psig.

Pressure Opening Valve

Remove the plastic stopper from the tapped hole in the

underside of the bonnet. Install a 1/4” or 3/8” tube fitting (not

provided). The tubing must be installed from your source of

instrument gas. The fitting at the top of the bonnet is a Breather

Plug.

Pressure Closing Valve

Remove the plastic stopper from the tapped hole in the top side

of the bonnet. Install a 1/4” or 3/8” tube fitting (not provided).

The tubing must be installed from your source of instrument gas.

The fitting in the lower half of the bonnet is a Breather Plug.

NOTE:

Never stand directly over or in front of a valve when the system

is pressurized. The valve could suddenly open, blowing debris

into the person’s face and eyes.

WARNING:

Before any service, be certain that the valve is fully isolated and

that all pressure upstream and downstream has been relieved.

Use bypass valves or fully shut off the process.

Be sure that any operating or instrument gas lines has been

disconnected. Never assume that a check valve is fully blocking

the downstream line. Never tighten any fitting or the main

connections to the regulator while there is pressure on the line.

A leaking valve indicates that service is required. Failure to take

the valve out of service immediately may create a hazardous

condition.

Verify all pressure connections are tight before pressurizing the

system.

NOTE:

When a gasket seat is disturbed during disassembly a new

gasket should be installed during re-assembly to ensure proper

sealing.

Repair kits are available. contacting the Kimray Inc, sales office

or a sales/applications representative for the correct repair kit

number.