2

Installation

32

Series N8700 User’s Guide

Output Noise and Impedance Effects

To minimize the noise pickup or radiation, the load wires and remote

sense wires should be twisted-pairs to the shortest possible length.

Shielding of sense leads may be necessary in high noise

environments. Where shielding is used, connect the shield to the

chassis via a rear panel ground screw. Even if noise is not a concern,

the load and remote sense wires should be twisted-pairs to reduce

coupling, which might impact the stability of power supply. The sense

leads should be separated from the power leads.

Twisting the load wires reduces the parasitic inductance of the cable,

which could produce high frequency voltage spikes at the load and

the output because of current variation in the load itself.

The impedance introduced between the power supply output and the

load could make the ripple and noise at the load worse than the noise

at the power supply rear panel output. Additional filtering with

bypass capacitors at the load terminals may be required to bypass the

high frequency load current.

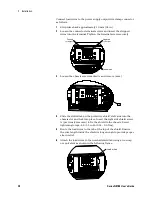

Inductive Loads

Inductive loads can produce voltage spikes that may be harmful to

the power supply. A diode should be connected across the output.

The diode voltage and current rating should be greater than the

power supply maximum output voltage and current rating. Connect

the cathode to the positive output and the anode to the negative

output of the power supply.

Where positive load transients such as back EMF from a motor may

occur, connect a surge suppressor across the output to protect the

power supply. The breakdown voltage rating of the suppressor must

be approximately 10% higher than the maximum output voltage of the

power supply.

Battery Charging

CAUTION

If a battery or external voltage source is connected across the output and the

output is programmed below the battery or external voltage source, the power

supply will continuously sink current from the external source. This could

damage the power supply.

To avoid damaging the power supply, insert a reverse blocking diode

in series with the + output connection of the power supply. Connect

the diode’s cathode to the + battery terminal or external voltage

source. Connect the diode’s anode to the + output terminal of the

power supply.