4

2.0 Installation Instructions

2.1 Mounting Instructions

2.1.1 Location Considerations.

Care should be taken when locating equipment behind the MMI to ensure

that AC power wiring, PLC output modules, contactors, starters and relays,

and any other source of electrical interference are located away from the

back of the unit.

Particular note should be taken to the position of variable speed drives and

switching power supplies. Their input and load cables should be screened to

a central star earth point.

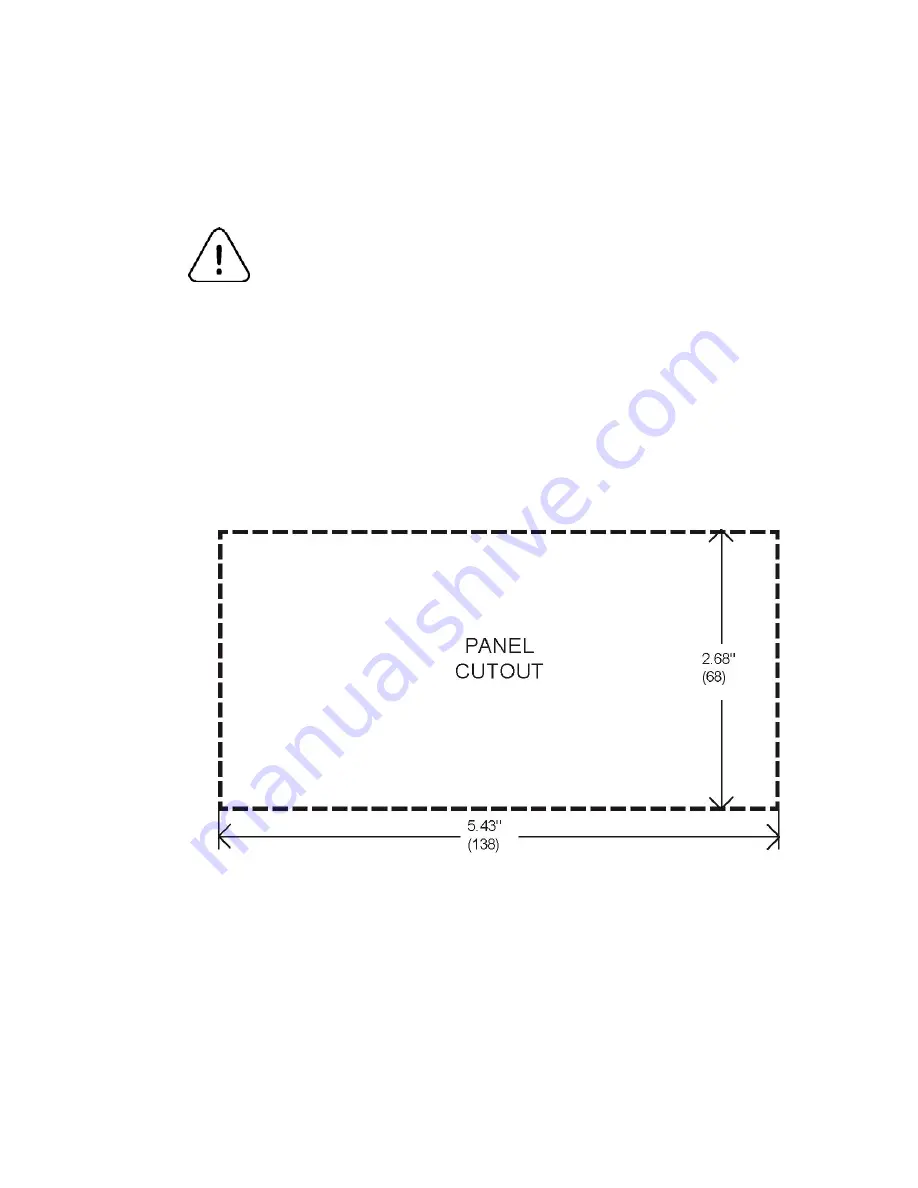

2.1.2 Making a NEMA-4 Mounting.

Panel

Details

The MMI can be mounted into panels with a depth of 6"(152mm). It is

recommended that the MMI be mounted on the front panel of a steel

enclosure, through a 5.43"(138mm) X 2.68"(68mm) opening. Allow a

clearance of 1"(25mm) on each side of the unit for mounting hardware.

Allow clearance for cable connections to the back of the unit. Unit depth

may vary according to cable type used. Typically, plan a depth to

accommodate at least 5"(130mm) behind the panel.

Содержание MMI-1 Series

Страница 2: ......