38 Maintenance and inspection

C 1200

Check list for the safe operation of the CHAMPION

Remember that the standard tightening torque for M12 screws (70 Nm) does

not apply to the special attaching bolts order no. 55205 for the flywheel

cutting disc knives. These bolts have to be pulled up to 130 Nm torque. On

grounds concerning your safety and your warranty rights we must insist on

the use of a torque wrench when these bolts are tightened.

Intake drum

Check the bearings and the attaching bolts of the large intake drum.

Cutting knives

Check state, sharpness and positioning of the knives and the cleaners. To

avoid imbalance always replace opposite knives or cleaners by pairs.

Support wheel

Tightened wheel studs periodically.

Feed mechanism

Check the state of pecompression rollers, feed rollers and bearings.

NOTE: The stripper bar on the rear smooth roller must always be located

close to the roller without impairing its rotation.

Shear bar

Remember that your forage harvester is a maxi-output machine which

should be kept in good condition at all times. Because of most of the power

is required by the chopping unit, the position of the shear bar should be

checked daily.

Flywheel cutting

disc

Safe operation of the flywheel cutting disc can be only ensured if the contact

surface of the knives is clean and the attaching bolts are pulled up to the

correct torque. Operate the forage harvester with sharp and undamaged

knives only. This will ensure a good chopping quality and keeps power

requirement low. Readjust the flywheel cutting disc centrally!

Smooth friction

concave plate

Both plates must be kept in good condition.

Hydraulic system

Make certain that all hoses and couplers are in good condition.

The V-belt drive

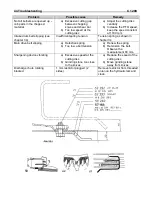

The V-belt drive (fig. 30 A) includes a 3 HB power band belt which is held at

the correct tension by means of a pressure spring 12. When installing the

belt the spring has to be set to the correct tension.

Hydraulically

slewable discharge

chute

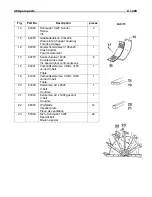

Before operating the machine check the function of the hydraulically

slewable chute. Sudden blockades can be caused by a grain of sand which

has plugged the restrictor 74, fig. 54 (both sides).

Содержание Champion C 1200

Страница 13: ...10 Designation of assembly groups C 1200 ...

Страница 15: ...12 Champion harvesting technology C 1200 ...

Страница 17: ...19 Technical instructions C 1200 ...

Страница 19: ...19 Technical instructions C 1200 ...

Страница 29: ...30 Operating instructions C 1200 ...

Страница 42: ...32 2 Blade rotor C1200 Installation position ...

Страница 45: ...35 Greasing chart C 1200 ...

Страница 47: ...35 Greasing chart C 1200 ...

Страница 48: ...35 Greasing chart C 1200 ...

Страница 51: ...38 Maintenance and inspection C 1200 ...

Страница 53: ...38 Maintenance and inspection C 1200 ...

Страница 55: ...40 Electric circuit diagram C 1200 ...