1

!"#$%#$&

!"#$%#$&

!"#$%#$&

!"#$%#$&''''

………………………………………………………………………………...3

…………………………………………………………………………………………….3

……………………………………………………………………………...3

……………………………………………………………………………3

………………………………………………………………………………..4

……………………………………………………………………....6

……………………………………………………………………7

……………………………………………………………8

………………………………………………………9

…………………………………………………………………………………….10

…………………………………………………………………………….10

…………………………………………………………………12

………………………………………………………………….14

………………………………………………………………16

……………………………………………………………………..18

………………………………………………………………………20

…………………………………………………………………………22

…………………………………………………………………………………..24

…………………………………………………………………………..26

………………………………………………………………………… 28

Control Box Operation Instruction

……………………………………………………………30

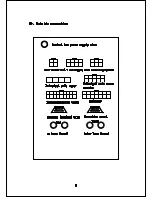

1 Control box hardware specifications......................................................................................................... 30

1.1

Power specification....................................................................................................................... 30

1.2

Replace the fuse ............................................................................................................................ 30

1.3

X/Y origin detector ....................................................................................................................... 30

1.4

Motors installation ........................................................................................................................ 30

1.5

Inner structure of the Control Box ................................................................................................ 31

2 Operation of the Sewing Machine ............................................................................................................ 32

2.1

Keys Description........................................................................................................................... 32

2.2

Adjusting zero position ................................................................................................................. 34

2.2.1

Adjusting the position of the induction rion for the sensor of the needle upper position....34

2.3

Basic operation.............................................................................................................................. 35

2.4

Transfering patterns by a USB disk .............................................................................................. 38

2.5

Adjusting system parameters ........................................................................................................ 39

3 Pattern Inputing......................................................................................................................................... 40

3.1

Create a new pattern...................................................................................................................... 40

3.2

Modify an existing pattern ............................................................................................................ 47

3.3

Input select key ............................................................................................................................. 48

3.4

Pattern input key ........................................................................................................................... 49

3.5

Section moving, rotation and copy ............................................................................................... 50

3.6

Pattern for non-stitch feeding........................................................................................................ 51

3.7

Inserting stitch quickly.................................................................................................................. 52

3.8

Translation of the pattern/Change pattern center F1

.............................................................. 53

3.9

Re-Curve F2 ........................................................................................................................... 53

Содержание GA204-107

Страница 1: ...BT 11020 RP TB PARTS INSTRUCTION MANUAL...

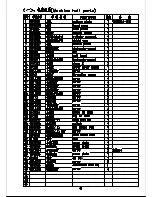

Страница 8: ...00 1 2 3 4 5 2 50 054 5 652257 5 58 9 5 4 4 57 22 4 5 3 257...

Страница 9: ......

Страница 10: ...0 1 2 3 4 2 3 4 3 5 6 503 7 3 4 8 3 9 9 2 5 5 0 0 5 0 5 5 3...

Страница 11: ......

Страница 12: ......

Страница 13: ......

Страница 14: ......

Страница 15: ......

Страница 16: ......

Страница 17: ......

Страница 18: ......

Страница 19: ......

Страница 20: ......

Страница 21: ......

Страница 22: ......

Страница 23: ......

Страница 24: ......

Страница 25: ......

Страница 26: ......

Страница 27: ......

Страница 28: ......

Страница 29: ......

Страница 30: ......

Страница 31: ......

Страница 32: ......

Страница 33: ......

Страница 34: ......