F96VTN and G96VTN: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

26

For direct vent (2-pipe) applications, seal the gas pipe knockout to

prevent air leakage.

Remove the required knockout. Install the grommet in the knockout.

Then insert the gas pipe. The grommet is included in the loose parts bag.

Piping should be pressure and leak tested in accordance with the current

addition of the NFPA 54/ANSI Z223.1 in the United States, local, and

national plumbing and gas codes before the furnace has been connected.

Refer to current edition of NSCNGPIC in Canada. After all connections

have been made, purge lines and check for leakage at furnace prior to

operating furnace.

PRESSURE TESTING ABOVE

½

psig:

The furnace and it’s individual shut-off valve must be disconnected from

the gas supply piping system during any pressure testing of that system

at test pressures in excess of

½

psig (3.5 kPa).

PRESSURE TESTING BELOW

½

psig:

The furnace must be isolated from the gas supply piping by closing its

individual manual shut-off valve during any pressure testing of the gas

supply piping system at test pressures equal to or less than

½

psig (3.5

kPa).

An accessible manual equipment shutoff valve MUST be installed

external to furnace casing and within 6 ft. (2 M) of furnace.

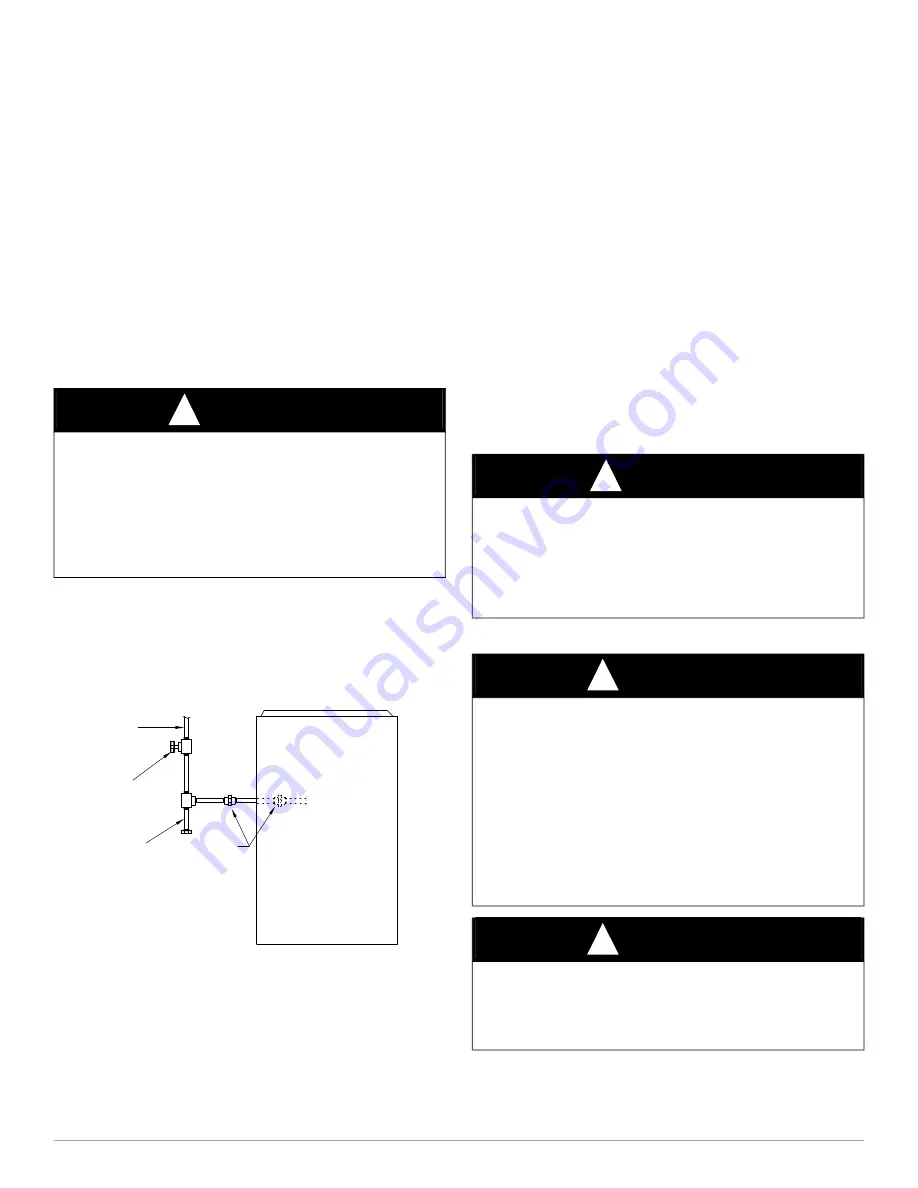

Install a sediment trap externally in the riser leading to furnace as shown

in

.

Connect a capped nipple into lower end of tee. Capped nipple

should extend below level of furnace gas controls. Place a ground

joint

union between furnace gas control valve and exterior manual

equipment

gas shutoff valve.

A11035

Fig. 31 – Typical Gas Pipe Arrangement

A 1/8-in. (3 mm) NPT

plugged tapping, accessible for test gauge

connection, MUST be

installed immediately upstream of gas supply

connection to

furnace and downstream of manual equipment shutoff

valve.

Piping should be pressure and leak tested in accordance with the current

addition of the

NFPA 54/ANSI Z223.1 in the United States, local, and

national plumbing and gas codes before the furnace has been

connected.

Refer to current edition of NSCNGPIC in Canada. After all connections

have been made, purge lines and

check for leakage at furnace prior to

operating furnace.

NOTE:

The furnace gas control valve inlet pressure tap connection

is

suitable to use as test gauge connection providing test

pressure DOES

NOT exceed maximum 0.5 psig (14-in. w.c.) stated

on gas control valve.

If pressure exceeds 0.5 psig (14-in. w.c.), gas supply pipe must be

disconnected from furnace and capped before and during supply

pipe

pressure test. If test pressure is equal to or less than 0.5 psig

(14-in. w.c.),

turn off electric shutoff switch located on furnace gas control valve and

accessible manual equipment shutoff valve before and during supply

pipe pressure test. After all connections have been made, purge lines and

check for leakage at furnace prior to operating furnace.

The gas supply pressure shall be within the maximum and minimum

inlet supply pressures marked on the rating plate with the furnace

burners ON and OFF.

Gas entry can be from left or right side, or top panel. See

Gas Pipe Grommet

For direct vent (2-pipe) applications, the knockout for the gas pipe must

be sealed to prevent air leakage. Remove the knockout, install the

grommet in the knockout, then insert the gas pipe. The grommet is

included in the loose parts bag. See

ELECTRICAL CONNECTIONS

See

for field wiring diagram showing typical field 115-v wiring.

Check all factory and field electrical connections for tightness.

Field-supplied wiring shall conform with the limitations of 63

_

F (33

_

C)

rise.

WARNING

!

FIRE OR EXPLOSION HAZARD

A failure to follow this warning could result in personal injury, death,

and/or property damage.

If local codes allow the use of a flexible gas appliance connector,

always use a new listed connector. Do not use a connector which has

previously served another gas appliance. Black iron pipe shall be

installed at the furnace gas control valve and extend a minimum of 2-in.

(51 mm) outside the furnace.

GAS

SUPPLY

MANUAL

SHUT OFF

VALVE

(REQUIRED)

SEDIMENT

TRAP

UNION

NOTE: Union may be inside th

e

vestibule where permitted by

local codes.

FRONT

CAUTION

!

FURNACE MAY NOT OPERATE HAZARD

Failure to follow this caution may result in intermittent furnace

operation.

Furnace control must be grounded for proper operation or else control

will lock out. Control must remain grounded through green/yellow wire

routed to gas valve and manifold bracket screw.

WARNING

!

ELECTRICAL SHOCK, FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings could result in dangerous operation,

serious injury, death or property damage.

Improper servicing could result in dangerous operation, serious injury,

death or property damage.

-

Before servicing, disconnect all electrical power to furnace.

-

When servicing controls, label all wires prior to disconnection.

Reconnect wires correctly.

-

Verify proper operation after servicing.

-

Always reinstall access doors after completing service and

maintenance.

WARNING

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death.

Blower door switch opens 115-v power to control. No component

operation can occur. Do not bypass or close switch with blower door

removed.