6.6

Operation

6.6

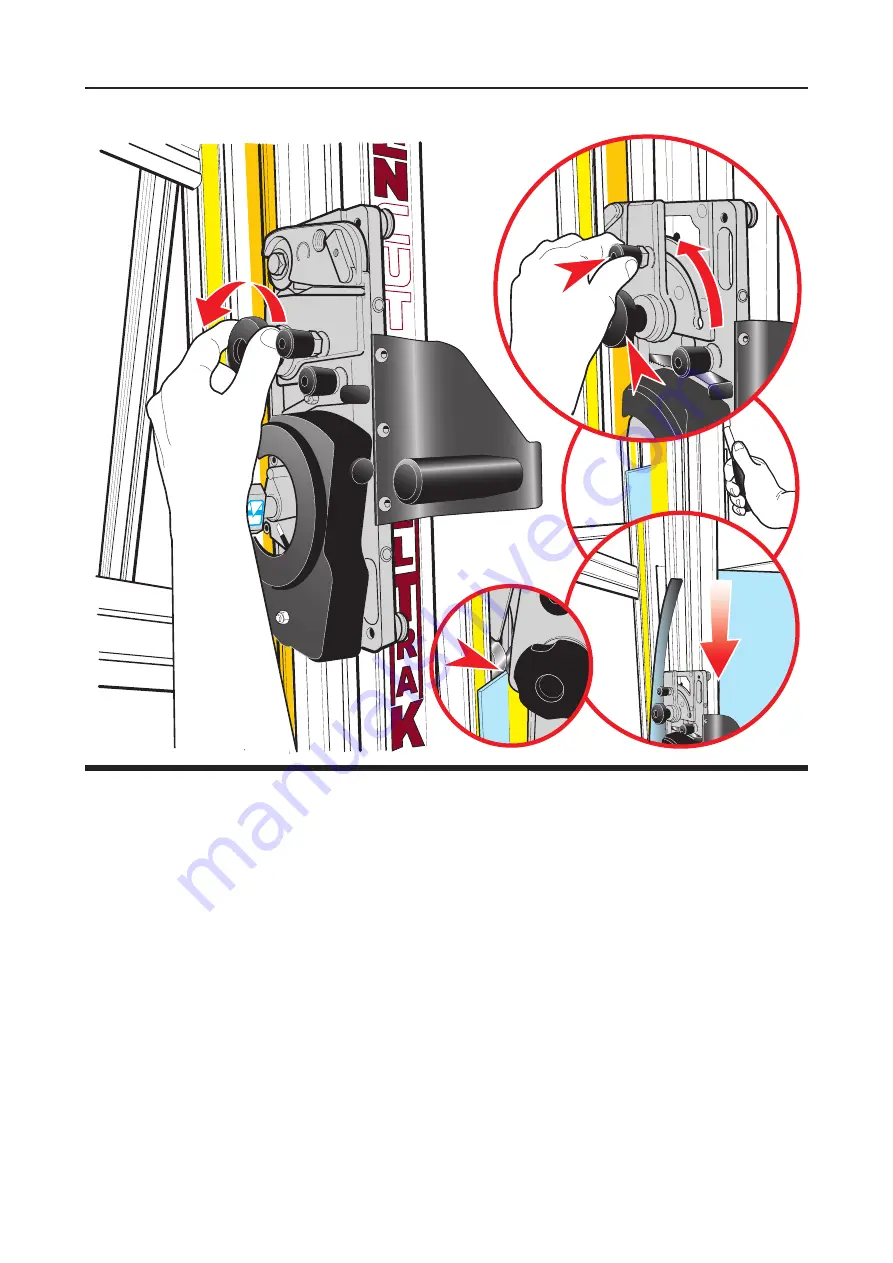

The Twin Wheel (TW) Cutter

The Twin Wheel Cutter is mounted on the upper part of the cutting head and is used

for cutting a range of tough, rigid materials. The standard machine is fitted with the

Composite TW Cutter and is used for cutting composite boards such as Dibond

®

and

other materials including MDF, Masonite and Hardboard up to 4mm. Many other softer

boards and card can also be cut, trials should be carried out to ensure the desired

quality of cut is obtained.

1. Engage the TW cutter by loosening the large hand knob (1/4 turn).

2. Depress the locking button and rotate the cutter 90 degrees until the locking button

springs out to its rest position, tighten the hand knob firmly.

NOTE: The TW cutter will interfere with the Sightline Strip as it is being engaged, either

engage the cutter at the top end of the machine or cut away a portion of the sightline

strip at a convenient height (e.g. adjacent to the clamp handle) and move the cutter to

this position for engaging/disengaging.

3. Ensure the TW cutter is above the height of the top edge of the board, position the

material in the machine and apply the clamp.

4. Bring the twin wheel cutter down until it makes contact with the top edge of the

material and stop. Take a firm grip and then push the cutter down through the

material without stopping.

1

2

3

4