10

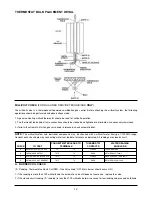

SERVICE DIAGNOSIS

The following diagnosis is only to be used as a guide to qualified service personnel. Keating recommends that you use a qual-

ified & licensed service company. (Equipment still under warranty requires it.)

NOTE:

To correctly and quickly diagnose the system, the chart below should be followed in sequential order.

TROUBLE SHOOTING CHART

PROBLEM

PROBABLE CAUSE

SOLUTION

No Pilot

a. Gas supply not “ON”.

b. Air in gas lines.

c.

Quick disconnect not engaged.

d.

Gas valve is on “OFF” position.

e.

Faulty Piezo Ignitor.

a.

Open gas supply valve.

b.

Press gas valve knob in “pilot”

position and hold.

c.

Reconnect quick disconnect.

d.

Turn valve knob to “pilot”.

e.

Replace ignitor.

Pilot won’t stay on

a. Loose wires.

b. Faulty thermopile.

c. Inadequate gas supply.

d. Bad gas valve.

a. Tighten connections on all wires.

b.

Replace thermopile.

c.

Increase line pressure.

d.

Replace gas valve.

Pilot on but no main burner ignition

a. ON/OFF switch is in “OFF” position.

b. Gas valve is in “pilot” position.

c. Thermostat is not turned on.

d. Low gas presssure.

e. Gas valve failure.

a.

Put ON/OFF switch to “ON” position.

b.

Turn knob to “ON” position.

c.

Turn thermostat to desired temperature.

d.

Set manifold pressure to 4” WC

(nat),10” WC (LP).

e.

Replace valve.

Temperature of griddle erratic

a. Thermostat is not calibrated.

b. Air from exhaust hood excessive.

a.

Calibrate thermostat with exhaust

system running.

b.

Have exhaust hood inspected and

air flow balanced.

Griddle stays hot or overheats

a. Thermostat is not calibrated.

b. Thermostat failure

c. Air from exhaust hood excessive.

d. Improper Cooking Procedured.

a.

Calibrate thermostat.

b.

Replace thermostat.

c.

Have exhaust hood inspected and

air flow balanced.

d.

See Cooking Procedure section.

Burners will not shut off

a. Thermostat is not calibrated.

b. Thermostat failure

c. Bad gas valve.

a. Calibrate thermostat.

b. Replace thermostat.

c.

Replace gas valve.

Flames pulsate.

a. Low gas pressure

b. Orifice is dirty or clogged

c. Air from exhaust hood excessive

a. Set manifold pressure to 4” WC (nat),

10”WC (LP). Set line pressure to 7” WC

(nat), 11” WC (LP).

b. Clean orifice

c. Have exhaust hood inspected and air

flow balanced.

Содержание SERIES 2000

Страница 17: ......