8.5 Water system installation

Connection requirements of chilled water pipes

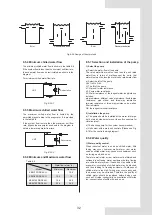

a) All chilled water pipelines should be thoroughly

flushed, to be free of any impurity, before the unit is

operated. Anyimpurity should not be flushed to or into

the heat exchanger.

b) Water must enter the heat exchanger through the

inlet; otherwise the performance of the unit will decline.

c) The inlet pipe of the evaporator must be provided with

a target flow controller, to realize flow-break protection

for the unit. Both ends of the target flow controller must

be supplied with horizontal straight pipe sections whose

diameter is 5 times that of the inlet pipe. The target flow

controller must be installed in strict accordance with

“Installation & Regulation Guide for Target Flow

Controller” (Fig.8-28,8-29). The wires of the target flow

controller should be led to the electric cabinet through

shielded cable (see Electric Controlling Schematic

Diagram for details). The working pressure of the target

flow controller is 1.0MPa, and its interface is 1 inch in

diameter. After the pipelines are installed, the target flow

controller will be set properly according to the rated

water flow of the unit.

d) The pump installed in the water pipeline system

should be equipped with starter. The pump will directly

press water into the heat exchanger of the water system.

e) The pipes and their ports must be independently

supported but should not be supported on the unit.

f) The pipes and their ports of the heat exchanger should

be easy to disassemble for operation and cleaning, as

well as inspection of port pipes of the evaporator.

g) The evaporator should be provided with a filter with

more than 40 meshes per inch at site. The filter should

be installed near to the inlet port as much as possible,

and beunder heat preservation.

h) The by-pass pipes and by-pass valves as shown in

Fig.8-23 must be mounted for the heat exchanger, to

facilitate cleaning of the outside system of water

passage before the unit is adjusted. During

maintenance, the water passage of the heat exchanger

can be cut off without disturbing other heat exchangers.

i) The flexible ports should be adopted between the

interface of the heat exchanger and on-site pipeline, to

reduce transfer of vibration to the building.

j) To facilitate maintenance, the inlet and outlet pipes

should be provided with thermometer or manometer.

The unit is not equipped with pressure and temperature

instruments, so they need to be purchased by the user.

k) All low positions of the water system should be

providedwith drainage ports, to drain water in the

evaporator and the system completely; and all high

positions should be supplied with discharge valves, to

facilitate expelling air from the pipeline. The discharge

valves and drainage ports should not be under heat

preservation, to facilitate maintenance.

l) All possible water pipes in the system to be chilled

should be under heat preservation, including inlet pipes

and flanges of the heat exchanger.

m) The outdoor chilled water pipelines should be

wrapped with an auxiliary heating belt for heat

preservation, and the material of the auxiliary heat belt

should be PE, EDPM, etc., with thickness of 20mm, to

prevent the pipelines from freezing and thus cracking

under low temperature. The power supply of the heating

belt should be equipped with an independent fuse.

n) The temperature sensor of the total outlet water of No.

0 master unit needs to be installed in the main outlet

water pipe of the project.

After the unit is in place, chilled water pipes

can be laid.

The relevant installation regulations should

be abided with when conducting connection

of water pipes.

The pipelines should be free of any impurity,

and all chilled water pipes must conform to

local rules and regulations of pipeline

engineering.

CAUTION

8.5.1 Basic requirements of connection

of chilled water pipes

NOTE

When the power cord is parallel to the signal wire,

make sure that they are enclosed in respective

conduits and are kept a reasonable wire spacing.

(Distance between the power cord and signal wire:

300mm if below 10A, and 500mm if below 50A)

WARNING

For the water pipeline network including

filters and heat exchangers, dreg or dirt may

seriously damages the heat exchangers and

water pipes.

The installation persons or the users must

ensure the quality of chilled water, and

de-icing salt mixtures and air should be

excluded from the water system, since they

may oxidize and corrode steel parts inside

the heat exchanger.

When the ambient temperature is lower than

2

℃

, and the unit will be not used for a long

time, water inside the unit should be drained.

If the unit is not drained in winter, its power

supply should not be cut off, and the fan coils

in the water system must be provided with

three-way valves, to ensure smooth

circulation of the water system when the

anti-freezing pump is started up in winter.

For

KEM-180 DRS5 KH

, the temperature

sensor of the total outlet water of

the master unit module A (the uint

address of DIP switches is 0) must be

repositioned on the water outlet main of

the project.

30