Operating Manual

Original Operating Manual

21

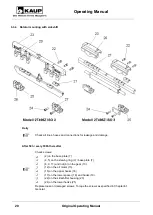

Weekly

Grease:

Sliding pieces (21) by way of the greasing nipples (20).

Supporting rollers (26) on the lower hooks (27) as necessary.

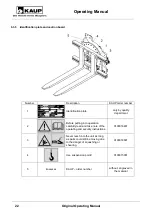

Every 200h

Check wear on:

Sliding pieces (21).

Supporting rollers (26).

Prevent entry of dirt, water or moisture into the slewing ring.

Grease:

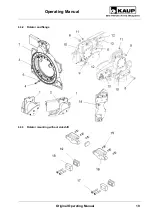

Slewing ring (3) by way of the greasing nipples (14).

Gearing of the rotary joint (3) by way of the greasing nipples (1).

Every 500h

Check the oil level of the gear box (10).

After 2500h / every 2000h thereafter

Change the gear box oil (Information KAUP customer service).

Yearly

Check the clearance in the rotary joint (3). (Information KAUP customer service)

As necessary

Renew worn sliders (21) by removing the hooks (25). Remove the complete rotating

fork positioner in the reverse order to that described in section 4.1. Replace the

sliders (21). During installation pay close attention that the sliders (21) are seated

correctly. Then fit the complete rotating fork positioner as described in section 4.1.

Replace defective supporting rollers (26) in the hooks (25) by removing the screws

(24). Using suitable hoisting gear tilt the complete rotating fork positioner forwards

away from the fork carriage on the lift truck. Remove the bolts (27) in the hooks (25),

remove the defective supporting rollers (26) and replace them with new ones.

Remount the complete rotating fork positioner in the reverse order.