14

PAGE

Repair Instructions

K 350

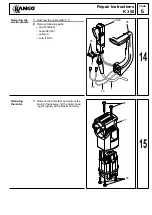

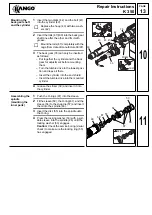

Assembling the

spindle

(mounting the

outer parts)

1

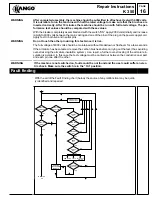

Mount the cup springs (47) (see illustra-

tion).

2

Mount the clutch (the stop washer (48)

with indentations against the toothing of

the spindle gear (49)).

3

Fit the spring ring (50) and press it

on (against the pressure of the cup

springs (47)).

4

Mount the slides (43) and the retaining

plate (45).

5

Mounting the rear thrust bearing assem-

bly:

– profile ring with damper O-ring (51)

– two compensating washers (65)

– thrust bearing (52)

– washer (58)

6

Secure the rear thrust bearing assembly

with the locking washer (53).

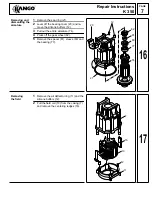

Mounting

the spindle

1

Fasten the spindle (46) to the motor hous-

ing (27) with the two screws (85) (6 Nm,

for additional security use Loctite 222 or

Omnifit.).

2

Push the ring gear (38) over the back gear

shaft (29) and let it engage in the locking

slide (43).

3

Push the planetary gear (37) onto the

back gear shaft (29) and fit them into the

ring gear (38).

4

Push the straight pin (44) through the lock-

ing slide (43) and insert it into the motor

housing (27).

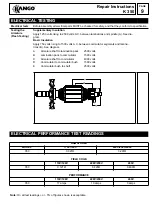

Mounting the

gear housing

1

Insert a service tool (A) into the gear (25)

(the sleeve protects the corrugated seal

ring inside the gear (25) from damage dur-

ing assembly).

2

Fit the gasket (87) to the gear

housing (25).

3

Fasten the gear box (25) to the motor

housing (27) and fix it with bolts (85)

(2,5+0,5Nm).

4

Fit the switch lever (87) (mount it in the

“hammer” position, the pin must grasp the

elongated hole of the locking slide).

53

45

43

50

49

48

47

51

65

58

52

12

43

85

46

27

44

37

38

29

13

A

25

87

27

87

85

14

Содержание K 350

Страница 1: ......