4

5451000

Fan 20V 120x120

545000

Fan guard 120x120

5459500

End cover f/OF01 and OF02 motors

5470500

Spare parts kit f/replacement of valve plate

f/OF01 and OF02 motors

5470520

Spare parts kit f/replacement of valve plate

f/OF01/OF02 (ø)

5499800

Kit f/cup seal OF01/OF02

5120

Drain bottle complete for metal cabinet Snapline

598000

Fan blade f/OF01/OF02 black CW

598010

Fan blade f/OF01/OF02 grey CCW

2952

Gasket, valve plate/cylinder head OF00

(silikone)

241800

O-ring f/1” plug - 2x5 mm

24710

O-ring f/plug Ø11.2x2.4 f/OF00

245800

O-ring Ø47x5 f/1 1/2” plug

25500

Vibration damper Ø0

2550

Vibration damper Ø20x20 f/cooling pipe

25701

Vibration damper f/OF00 / 2-00 Ø20x0

25400

Vibration damper f/OF01 20V

254500

Vibration damper Ø25x25 mm (M8x18)

295500

Grommet 170211

295900

Cable relief PG1

1407

Screw M x 10, PHD, Torx

17100

Nut M1 DIN49-B FZB

9900

Distance bolt f/metal cabinet

9901

Distance bolt long f/metal cabinet

40500

Unbraco plug 1/8”

40900

Unbraco bolt M5x10

41750

Unbraco bolt Mx8 original

90000

Star washer type A M

90100

Star washer type M14

90200

Star washer type A M1

92155

Screw torx M4x20 PH

452020

Teflon hose 1/4” 20 cm with elbow

452024

Teflon hose 1/4” 24 cm with elbow

452028

Teflon hose 1/4” 28 cm with elbow

45207

Teflon hose 1/4” 7 cm with elbow

452052

Teflon hose 1/4” 52 cm with elbow

951200

Wheel Ø75 mm

95100

Wheel Ø75 mm w/brake

984521

Cabinet plate complete size B-MD

984522

Cabinet plate complete size C-MD

98452

Cabinet plate complete size D-MD

98452

Cabinet plate complete size A-MD 120V

984527

Cabinet plate complete 20V

98451

Top A-MD & B-MD

984907

Back complete A-M Snapline

984908

Back complete A-D Snapline

984909

Door complete A-MD Snapline

984910

Mounting bracket C-M 200 V Snapline

984911

Mounting bracket C-D 200 V Snapline

984912

Front complete B-MD 400V Snapline

98491

Mounting bracket A-M B-M 200 V Snapline

984915

Back B-M 120V Snapline

98491

Back B-M 20V Snapline

984917

Back B-D 120V Snapline

984918

Back B-D 20V Snapline

984919

Door B-MD, C-MD and D-MD Snapline

984921

Mounting bracket complete A-D & B-D 200 V

Snapline

984924

Back C-MD 400V Snapline

984925

Back C-MD 20V Snapline

98491

Front complete B-MD 120V (max 1A) Snapline

98495

Back D-MD Snapline

98497

Mounting bracket complete D-M 20V Snapline

w/special auto drain for unloading

98498

Mounting bracket complete D-D 20V Snapline

w/special auto drain for unloading

98499

Front complete C-MD 400V Snapline

984940

Front complete A-MD 20V Snapline

984941

Front complete A-MD 120V Snapline

984944

Front complete B-MD 20V Snapline

984945

Front complete C-MD 120V Snapline

98494

Front complete C-MD 20V Snapline

984950

Front complete D-MD 400V Snapline

984957

Mounting bracket complete C-M 120V Snapline

984958

Mounting bracket complete C-M 20V (M2000

400V) Snapline

98490

Mounting bracket complete A-D & B-D 20V

Snapline

98491

Mounting bracket complete A-D & B-D 120V

Snapline

98492

Mounting bracket complete A-M & B-M 20V

Snapline

9849

Mounting bracket complete A-M & B-M 120V

Snapline

98494

Mounting bracket complete C-D 20V (M2000

400V) Snapline

98495

Mounting bracket complete C-D 120V (M2000

400V) Snapline

984970

Mounting bracket complete B-MD 20V

Snapline

984971

Mounting bracket complete B-MD 120V

Snapline

984972

Mounting bracket complete C-MD 20V & 400V

Snapline

98497

Mounting bracket complete C-MD 120V

Snapline

984977

Mounting bracket complete D-MD Snapline

985908

Mounting bracket A & B

985928

Mounting bracket size C

985948

Mounting bracket D

7020000

Double nipple 1/8”

7024000

Double nipple 1/4” L= 2 mm

7024002

Double nipple 1/4” w/o-ring track

7025000

Double nipple 1/4”x1/8”

702001

Bushing nipple

7070000

Connection piece f/non-return valve

Spare parts

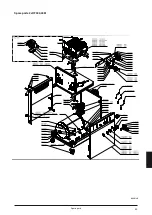

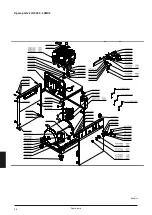

Содержание 2 OF302-40M Series

Страница 4: ......

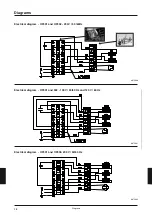

Страница 30: ...30 6072960 Electrical diagram OF301 and 302 M D Diagrams...

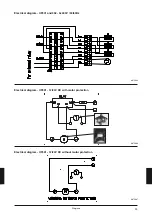

Страница 31: ...31 6073160 Electrical diagram 2xOF301 and 2x302 M D Diagrams...

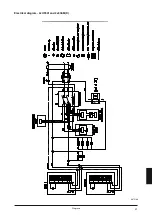

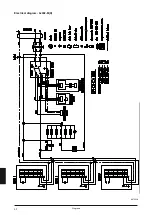

Страница 32: ...32 Electrical diagram 3x302 M D 6073250 Diagrams...

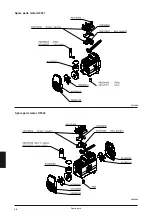

Страница 36: ...36 Spare parts motor OF301 0070000 0080000 Spare parts motor OF302 Spare parts...

Страница 37: ...37 Spare parts OF301 4M 0080120 Spare parts...

Страница 38: ...38 Spare parts OF301 4MD2 0080121 Spare parts...

Страница 39: ...39 Spare parts OF302 4M 0080122 Spare parts...

Страница 40: ...40 Spare parts OF302 4MD2 0080123 Spare parts...

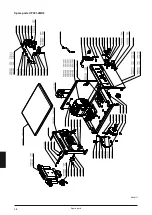

Страница 41: ...41 Spare parts OF302 25M 0080130 Spare parts...

Страница 42: ...42 Spare parts OF302 25MD2 0080131 Spare parts...

Страница 43: ...43 Spare parts 2xOF302 40M 0080140 Spare parts...

Страница 44: ...44 Spare parts 2xOF302 40MD2 0080141 Spare parts...

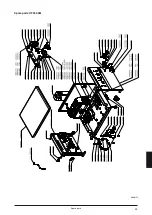

Страница 45: ...45 0080150 Spare parts 3xOF302 40M Spare parts...

Страница 46: ...46 0080151 Spare parts 3xOF302 40MD3 Spare parts...

Страница 47: ......