16

138301_Rev_G 10.4.11

Optional Wall Thermostat or

Remote Control

Use only a 750 millivolt DC two-wire circuit thermostat

with this appliance. The thermostat should be placed

in the same room as the heater, typically 5 feet off the

floor. Avoid drafty areas or any area that may affect the

accuracy of the thermostat.

The thermostat should be connected to the stove us

-

ing a minimum of 16 gauge wire with a maximum length

of 25 feet of wire.

Connect the two thermostat wire leads to the two

left terminals on the terminal block located directly

above the ignitor button. Do not overtighten the con-

nections.

IT IS NOT NECESSARY TO DISCONNECT ANY

OTHER WIRES.

See Fig. 26.

For thermostatic operation, the On/Off/T-Stat switch

on the back of the stove must be in the T-stat position,

and the pilot light must be running, as it is the power

source for the thermostat.

At the thermostat, the two wires should be connect-

ed to the two connection screws on the thermostat base

plate per the manufacturer’s instructions.

Remote Control

When using a remote, the remote receiver should be

wired to the terminal block the same way the thermo-

stat would be. See the instructions above.

Follow the operating instructions included with the

Remote Control unit.

CAUTION:

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN

SERVICING THE CONTROLS. WIRING ERRORS CAN CAUSE

IMPROPER OR DANGEROUS OPERATION. ALWAYS VERIFY

PROPER OPERATION AFTER SERVICING THE APPLIANCE.

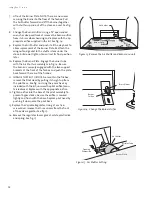

Figure 26. Valve and Accessory wiring diagram.

Flame Appearance / Air Shutter

Adjustment

This stove is shipped from the factory equipped to burn

Natural gas. If the stove has been converted for use with

propane, the Air Shutter may require adjustment to

achieve the desired flame appearance. Other installation

related variables can also affect the flame picture. The Air

Shutter may be opened or closed to provide the best flame

picture for your specific installation.

Too large an air opening

- the appliance will generate a

flame that is blue and transparent, or an “anemic” flame.

Too small an air setting

- the appliance will generate

very long yellow flames resulting in soot. Sooting pro-

duces black deposits on the logs, on the inside walls of the

appliance, and potentially on the exterior termination cap.

Sooting is caused by incomplete combustion in the flames

and lack of combustion air entering the air shutter open-

ing.

Air Shutter Adjustment should be done only by a qualified

gas technician.

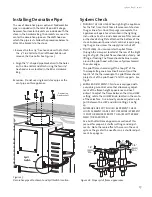

1. Reach under the right side of the stove and loosen the

wingnut located closest to you. See fig. 25. Slide the

wingnut stud forward to open the air shutter and back

to provide less air. Make adjustments in small incre

-

ments.

2. Tighten the wingnut to secure the shutter at the de-

sired setting.

3. Allow the stove to burn for 30 minutes on the HIGH set-

ting, observing the flame continuously. If the flame ap-

pears weak, slow, or sooty, repeat the process described

above until the flame is as desired.

Figure 25. Loosen the wingnut to adjust the air shutter.

TH

TP

TH

TP

ON

OFF

TSTAT

Yellow

Purple

White

Orange

Red

Black

White

Black