4

M9106-xGx-2 Series Electric Non-Spring Return Actuators Installation Instructions

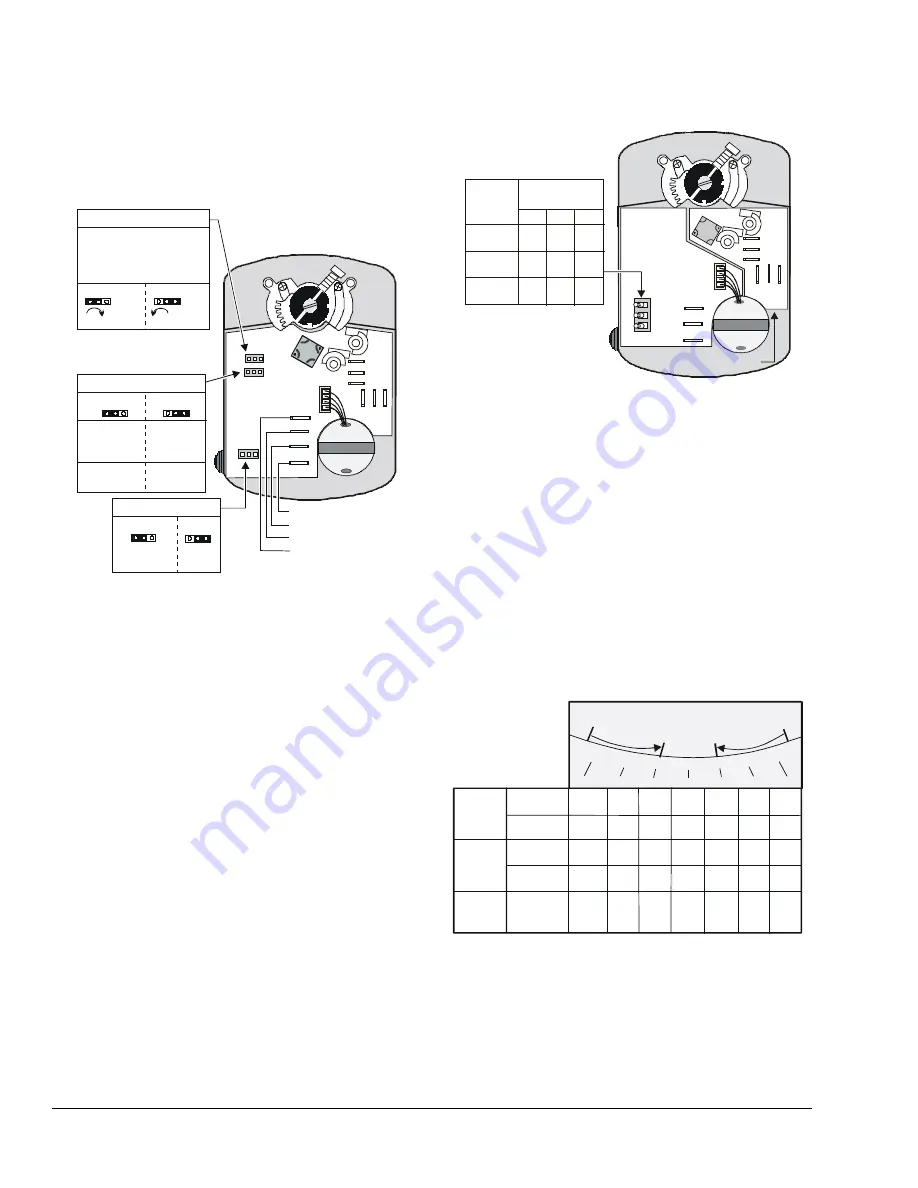

GGx Models

The M9106-GGx-2 proportional actuators are

factory set for Direct Acting (DA) mode with

Jumper W1 in the DA position. Remove Jumper W1

and place it in the RA position. (See Figure 7.)

(CW) DA

(CCW) RA

NC2

NO2

C2

C

1

N

C

1

N

O

1

FB

VDC/mA

+24

COM

Jumper W3

Factory Set

VDC

mA

Jumper W2

Jumper W1

Factory Set

Input

Input

0-10 VDC

0-20 mA

2-10 VDC

4-20 mA

Feedback

0-10 VDC

2-10 VDC

Direct Acting (DA)

Reverse Acting (RA)

Rotation Direction

with Increasing Signal

Factory Set

Note: Jumper W1 is not

available on the

floating models.

Common

+24 VAC Power

VDC/mA

Feedback Output

Figure 7: Calibrating the GGx Models

Jumpers (GGx Models)

The M9106-GGx-2 proportional actuators are

factory set with Jumper W2 in the 0 to 10 VDC position

and Jumper W3 in the VDC position.

The VDC/mA terminal is the control input signal.

Jumper W3 must be in the VDC position for

voltage input and in the mA position for current input.

The FB Terminal is the feedback output. (See

Figure 7.)

Mode Switches (IGx Models)

The M9106-IGx-2 models offer adjustable rotation

times of 1, 1.5, 2, 5.5, and 11 minutes (factory set for

1 minute). Switch settings determine the rotation time

of the IGx models. Refer to Figure 8 to position the

mode switches for the desired rotation time.

NC2

NO2

C2

C

1

N

C

1

N

O

1

Time

(Minutes)

1.0

1.5

2.0

5.5

11.0

1.0

Off

On

Off

On

Off

On

A

B

C

Off

Off

Off

Off

Off

Off

On

Off

On

On

On

On

Mode

Switch Settings

A

B

C

Note: The IGA models have Board 1, and the IGC models

have both Board 1 and Board 2.

Board 1

Board 2

COM

CW

CCW

Off On

Figure 8: Mode Switch Settings on IGx Models

The 1-, 1.5-, and 2-minute settings are ideal for on/off

and floating applications, and replace the

M9104-xGx-2 1.5-minute models. The 5.5- and

11-

minute settings are replacements for the 35 lb∙in

(4

N∙m) EDA-2040 and the ATP-2040 models.

Feedback Signal

The feedback signal will vary with a change to the

rotation range. For the GGA and GGC models, a

change to the rotation range changes the feedback

signal and the operating range proportionally. For the

AGF model, resistance feedback is reduced

corresponding to the reduced rotation range. (See

Figure 9.)

90°

90°

0.0V

2.0V

10.0V

8.7V 7.3V

6.0V 4.7V

3.3V

10.0V

8.3V

6.7V 5.0V 3.3V 1.7V

75°

75°

60°

60°

45°

45°

30°

30°

15°

15°

0°

0°

Rotation Range

2-10V

Feedback

0-10V

Feedback

Direct

Acting

10.0k

Ω

6.7k

Ω

1.7k

Ω

Ω

0

8.3k

Ω

0-10k ohms

Feedback

Ω

5.0k 3.3k

Ω

Direct or

Reverse

Acting

2-10V

Feedback

Reverse

Acting

0-10V

Feedback

0.0V 1.7V

3.3V 5.0V 6.7V

8.3V 10.0V

10.0V

8.7V

7.3V

6.0V

4.7V

3.3V

2.0V

Set Screw

Adjustment

Set Screw

Adjustment

Note:

0-10k ohms feedback is available on AGF models.

0-10V is available on GGA and GGC models.

Figure 9: Nominal Feedback Signal Relative to

the Rotation Range