VENTILATED

Low level grille

288cm

2

(44in

2

)

FROM INSIDE

BUILDING

High level grille

144cm

2

(22in

2

)

VENTILATED

Low level grille

144cm

2

(22in

2

)

FROM OUTSIDE

BUILDING

High level grille

72cm

2

(11in

2

)

Table 1: Minimum Effective Areas

4.

DUCT SYSTEM

(See British Design Manual - Gas fired Warm Air Heating)

4.1

RETURN AIR

4.1.1

All return air shall be POSITIVELY ducted from outside the compartment to the top of the unit via a return air

duct, or if appropriate, using a J & S Side Return Air Kit, and mechanically secured. It is recommended that the

return air duct be not routed directly from the main living area, but from a convenient central area serving the

remainder of the dwelling.

4.1.2

The return air system should be constructed of fire-resistant material. The flue shall not be run through an area

serving as a return air path. It is extremely important that the correct size of return air grilles and ducting is used.

For heaters on maximum output the return air duct size should not be less than the equivalent of 250mm x 200mm

(10" x 8"). If flexible duct is used the duct diameter should not be less than 300mm (12") dia. The return air

grille should have a free area of not less than 860cm

2

(137in

2

).

4.1.3

An adequate and unobstructed return air path is essential from areas not served by a directly ducted return and to

which warm air is delivered. All such rooms should be fitted with relief grilles which have a free area of

0.0088m

2

/kW (1in

2

/250Btu/h) of heat supplied to the room. The only exceptions are kitchens, bathrooms and

WC.’s.

4.1.4

The return air duct should allow for ease of removal for access to the flue.

4.1.5

All duct work in the room or internal space in which the heater is installed shall be mechanically secured, and

sealed with ducting tape.

4.2

WARM DELIVERED AIR

4.2.1

All duct work, including riser ducts, should be fully insulated with 50mm (2in) fibreglass or similar. If short

extended duct runs are taken below floor level these should be similarly insulated, and in addition wrapped with a

sound vapour proof barrier, and protected from crushing.

4.2.2

The duct system should be carefully designed (as given in the guidelines in the British System Design Manual) to

suit the needs of its specific heating requirements and building layout. The type of duct system, (i.e. radial/

extended plenum/stepped) should be installed using the least number of fittings to minimise airflow resistance.

The base duct, which equalises the air pressure to supply ducts, shall be constructed to support the weight of the

heater, which shall be secured to the plenum with screws on at least two sides, and sealed using self-adhesive

foam strip, ducting tape or sealing compound. All ducting and blanking plates shall be mechanically secured and

sealed.

5.

INSTALLATION REQUIREMENTS

Note: For circulator Installation Instructions, refer to the relevant instructions provided with the circulator.

5.1

FLUES

(see British Standards BS 5440 Pt. 1 Flues)

5.1.1

All joints shall be soundly sealed.

5.1.2

The flue should be kept as short and warm as possible.

5.1.3

Sufficient support brackets shall be installed to bear the weight of the total flue system.

5.1.4

The spigot connection of the heater draught diverter will accept internally the spigot end of a non-asbestos flue

to BS 567 or twin wall metal flue to BS 715 of nominal 100mm (4in) diameter.

5.1.5

A split collar should be fitted to provide for flue maintenance or inspection.

5.1.6

The flue shall be in accordance with the Building Regulations and British Gas Materials and Installations

specification (3rd edition) with regard to clearance and shielding from combustible materials.

5.1.7

All materials shall be in accordance with Building Regulations requirements.

3

18

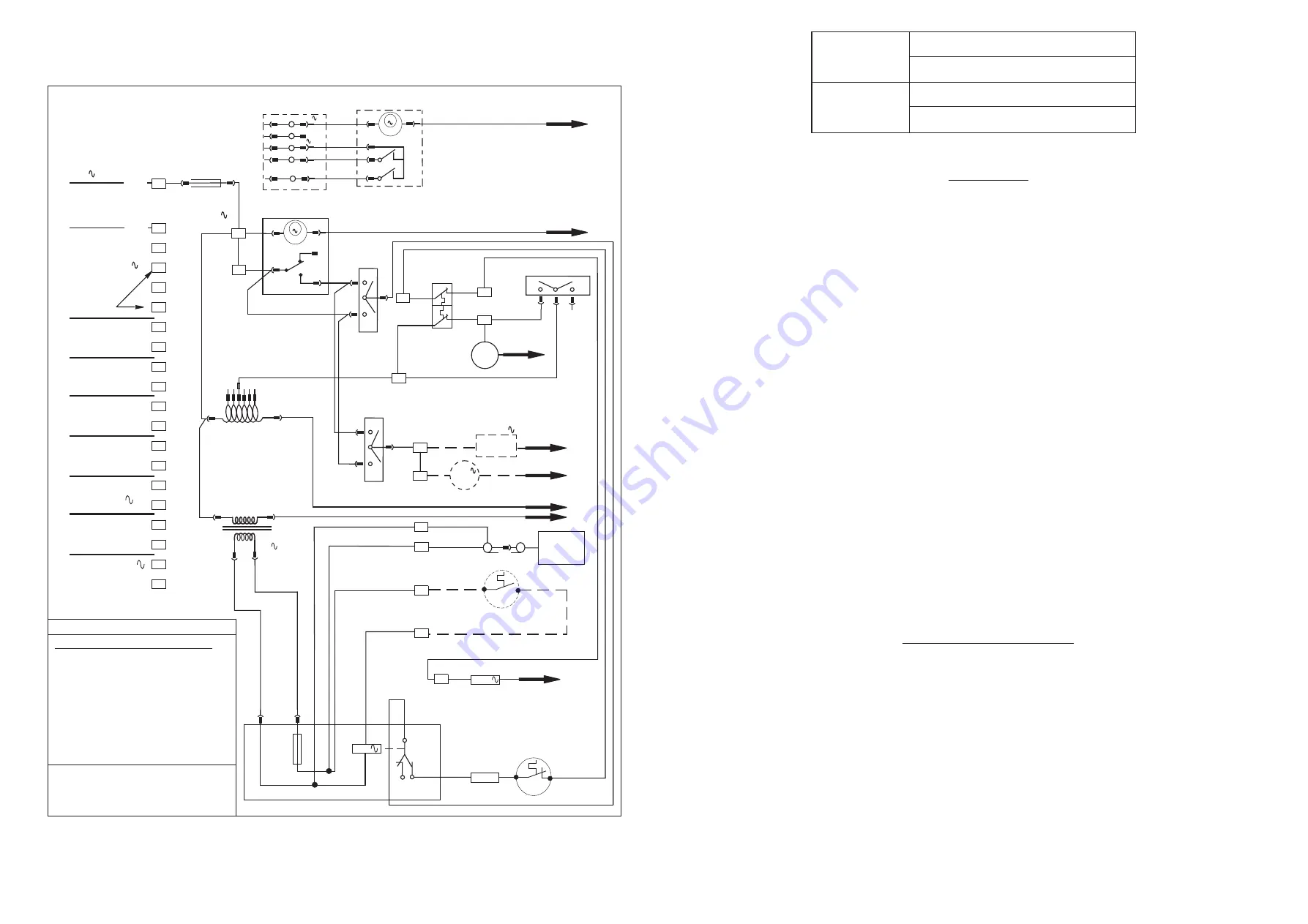

Fig. 6, FUNCTIONAL DIAGRAM

4

13

18

14

17

12

19

8

7

FELV * Connection

20

10

6

N

Timed

230V

Cont.

A

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

2

N

N

N

T

L

N

24V

0V

GE

L

L

Room Thermostat

Water Heater

(Optional)

Water Pump

(Optional)

Limit Switch

Multi-functional

Control 230V

Fan Delay

Control

Cleanflow

(Optional)

Wire colour code where indicated

*FELV Functional Extra-Low Voltage

NOTES:-

red-----------r

blue---------b

black-------bk

brown------br

white-------w

grey-------gy

orange---or

violet------v

yellow-----y

black/white------bk/w

purple/red-------p/r

green/yellow----g/y

N

N

N

N

N

N

CLOCK

C4

C5

C3

Link

gy

gy

b

r

r

bk

w

br

br

br

br

br

bk

p/r

p/r

y

r

y

v

r

bk

bk

br

r

or

r

r

r

bk

br

br

r

bk

1

230V 50Hz

Supply

L

br

S4

S6

S5

T

1

0

AIR

HTR.

S7

S9

S8

T

1

0

WATER

HTR.

L

Voltage

Selector

TX1

Summer

Air Flow

Limit

Switch

Fan Delay

Control

Fan

230V

PUMP

N

230V

(Optional)

(Optional)

(See

note)

(Optional)

SW

Comm.

n/o

24V

Cleanflow

Air

Cleaner

Water

Htr

T500mA

Relay Module

24V Thermostat

(Not Fitted)

15

230V

Multi-functional Control

N

br

br

b

Butt

Connector

br

w

Spill

Switch

(TTB)

or

or

S3

ON

S1

OFF

S2

1

1

0

EXTERNAL PROG.

OPTION

NO CLOCK

OPTION

Park S8 when no

water htr. or

for ext. prog.

N

C1

230V

N

WH

Timed

230V Cont.

AH(S5)

Timed

C2

C3

C6

S8

CH

WH

230V

Continuous

C2

C1

T3.15A

FUSE

br

M

M

TX2

24V

0V

L

N

Park conns when no

clock fitted or for

external prog.

If Superjan fitted remove red wire link

between terminals 10 &12