10

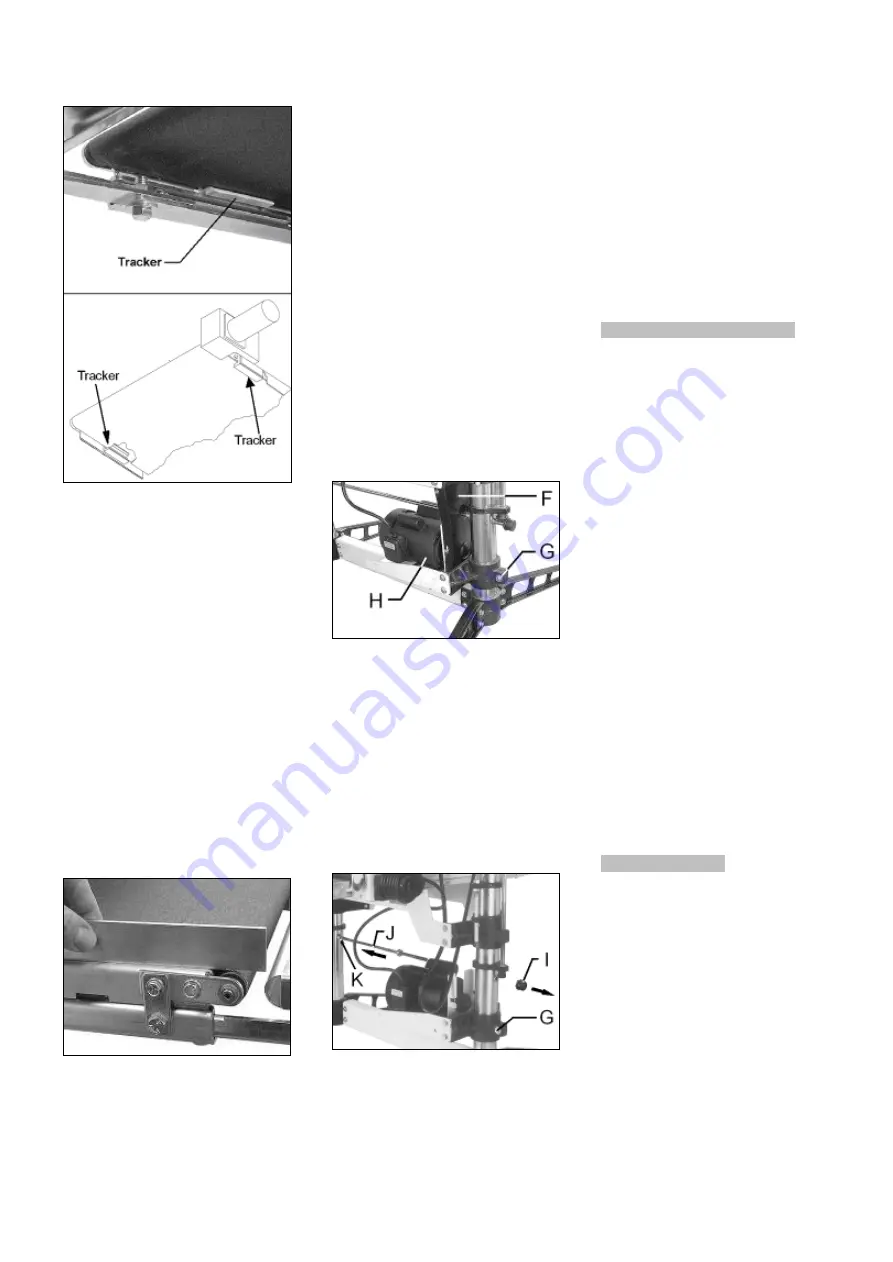

Fig 22

The Trackers are due to wear and can

be reversed.

Tracker Kit (2 pieces)

Jet Art. No.: 98-0080

Note:

There will be increased wear during

the break in time, which may white

mark the conveyor belt.

This has no negative effect to the

machine function.

Please assure to keep the belt tension

as low as possible until the belt and

ceramic guide blocks are worn in.

Note:

Make sure the conveyor bed is not

twisted, place a level on the conveyor

bed to check.

Check the conveyor drive roller to

make sure it is parallel to the surface

of the conveyor bed (Fig 23).

Fig 23

If not, loosen and adjust the bracket

that hold the roller in place.

7.8 Conveyor belt changing

Disconnect the machine from the

power source (pull mains plug).

Unplug the motor cord form the

control box.

Relieve the conveyor belt tension.

Remove four bolts attaching conveyor

assembly to the base.

Lift up and slide conveyor unit out to

the side of the machine.

Slide conveyor belt off the end of the

conveyor.

Reverse process for installation.

7.9 V-belt tensioning

Loosen the pinch-bolt (G, Fig 24) and

lower the motor (H) by its own weight

only.

Fig 24

Make sure the motor stays aligned.

Tighten the pinch-bolt (G).

7.10 V-belt replacement:

Disconnect the machine from the

power source (pull mains plug).

Remove the plastic belt guard (F).

Remove the bevel gear (I, Fig 25) and

loosen the collar (K).

Fig 25

Slide the transmission rod (J) to the

left.

Loosen the pinch-bolt (G) and rise the

motor (H).

Install new V-belt and lower the motor

by its own weight only.

Make sure the pulleys are aligned.

Tighten the pinch-bolt (G).

Replace transfer rod, bevel gear and

collar.

Install the belt cover (F).

8. Maintenance and inspection

General notes:

Maintenance, cleaning and repair

work may only be carried out after

the machine is protected against

accidental starting by pulling the

mains plug.

Check brush regularly for faults.

Replace a defective brush-drum

immediately.

Inspect the conveyor belt tracking

regularly.

Monthly lubricate all moving parts,

such as threaded rods, washers and

bushings.

Clean the machine regularly.

Inspect the proper function of the dust

extraction daily.

Defective safety devices must be

replaced immediately.

All protective and safety devices must

be re-attached immediately after

completed cleaning, repair and

maintenance work.

Repair and maintenance work on the

electrical system may only be carried

out by a qualified electrician.

9. Trouble shooting

Motor doesn’t start

*No electricity-

check mains and fuse.

*Defective switch, motor or cord-

consult an electrician.

Conveyor belt stops

*Improper belt tension-

Adjust belt tension.

*Shaft coupling loose-

Align shaft flats of gear motor and

tighten shaft coupling set screws.

Board slips on conveyor belt

*Dirty or worn conveyor belt-

Clean or replace conveyor belt.