9

Fig 17

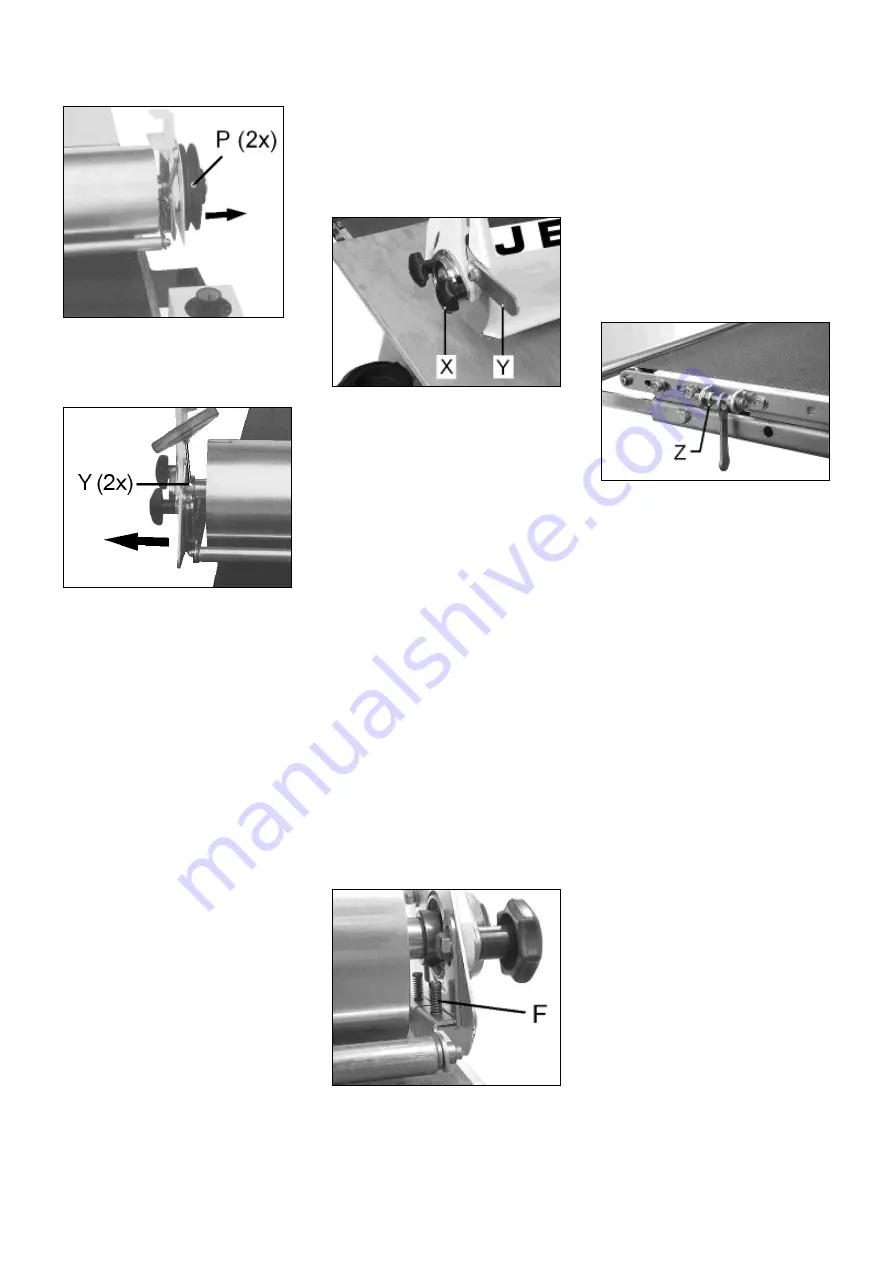

Loosen 2 grub screws each (Y, Fig

18) and slide off the 2 bearing

assemblies.

Fig 18

Change the brush.

Reinstall the brush-drum in the

reverse order:

- install the bearing assemblies

- (install the feed rods)!

- install the pulley

- install the V-belt

- move the table up (tightens the belt)

- re-attach the entire drum assembly

- re-install the dust hood

- Instpect for free rotation of the drum

and feed rods

- Make sure all screws are tight

- Start the machine with care.

7.3 Brush-drum alignment

The brush-drum is adjusted parallel to

the conveyor table ex works.

The brush-drum outboard bearing can

be adjusted up/down (Fig 19)

For optimum brushing of boards wider

than the drum, the drum alignment is

critical and must be exactly level or

slightly high on the outboard end.

Fine tuning brush-drum alignment:

Disconnect the machine from the

power source (pull mains plug).

Loosen the 2 star-knobs (X, Fig 19)

and raise the outboard end of the

drum with the adjust lever (Y).

Fig 19

Retighten the star knobs.

7.4 Brush Dressing

Nylon brushes may need “dressing “

of the bristle tips to maintain uniform

brush wear and to expose new grit on

the ends of the fiber.

Brush dressing instructions:

Staple a 60 grit sandpaper across a

flat wooden board.

Raise the board, so the tips of the

nylon-bristles contact the sandpaper

( by approx 0,5mm).

Pass the abrasive loaded board

through the machine, at a conveyor

feed rate of approximately 50%, until

the brush fibers are sharp and even.

7.5 Feed-roller adjustment

Feed roller pressuer is adjusted ex

works.

The feet roller pressure can be

adjusted on the compression springs

(F, Fig 20).

Fig 20

Note:

Insufficient feed roller pressure (or

feed rollers set too high) could allow

kickback or slippage of workpieces.

Too much pressure results in snipe

marks on the workpiece.

7.6 Conveyor belt tensioning

Adjust the take-up screw nut (Z, Fig

21) on both sides of the conveyor to

obtain approximately equal tension.

Fig 21

Attention

:

Do not apply high conveyor belt

tension.

The belt is tensioned correctly when it

can be stopped by hand pressure

applied directly to the top of the

conveyor belt.

Too high tension may cause belt

tracking problems (may overrule the

ceramic guide blocks).

Insufficient tension will cause slippage

of the conveyor belt on the drive roller

during brushing operation.

7.7 Conveyor belt tracking

The conveyor belt tracking is assured

by 2 white ceramic guide blocks

(=Trackers, Fig 22).

They eliminate further belt tracking

adjustments.