BELT-SANDER FOR WOODEN FLOORS

Leopard

Page 10

INSTRUCTION MANUAL

CARRYING THE MACHINE

WARNING:

Since the machine is heavy, disconnect the motor before moving it. Ask for help

in lifting the machine and the motor.

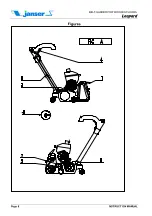

MOVEMENT WITH ONE PERSON

In order to make movement easier, the machine can be dismantled into three parts:

motor

suction tube

base with roller

Proceed as follows:

1.

Make sure that the power supply cable is disconnected from the mains and the machine.

2.

Open the belt guard after unscrewing the attachment screw.

3.

Loosen the belt stretcher using lever 2 (fig. A) and remove the belts.

4.

Loosen knob 3 (fig. A) until the socket washers on the motor support shaft come out of their

sites on the supports.

5.

Remove the motor and take it to the work site.

6.

After lowering lever 4 (fig. A), unscrew and extract knurled knob 5 (fig. A).

7.

Loosen nut 6 (fig. A), slip the tube off and take it to the work site.

8.

Lift the base by taking hold of it at the front and back. Rest the belt guard against the chest

and carry it to the work site.

In order to reassemble the machine after moving it, proceed as follows:

1.

Open the belt guard.

2.

Fit the motor in place and fix it by tightening knob 3 (fig. A).

3.

Fit the belts, stretch them and close the belt guard by tightening the respective screw.

CAUTION:

Excessive belt tension may cause the ball bearings to wear prematurely.

The roller belt must deflect by 8mm when a load of 30 N is placed in the middle.

The aspirator belt must deflect by 8mm when a load of 18 N is placed in the

middle.

4.

Fit the suction tube and roller control rod.

5.

Lift the roller using lever 4 (fig. A).

6.

Connect the power cable to the machine and mains.

MOVEMENT WITH TWO PEOPLE

In order to move the machine with two people, proceed as follows:

1.

One operator takes hold of the handle hand-grip.

2.

The second person lifts the machine using handle 1 (fig. A).