Page 14

ENGLISH

Jandy

®

Pro Series Water Feature Pump

|

Installation and Operation Manual

6.2 Service Technician Maintenance

WARNING

This pump must be serviced by a professional

service technician, qualified in pool/spa installation.

The following procedures must be followed exactly.

Improper installation and/or operation can create

dangerous electrical hazards, which can cause high

voltages to run through the electrical system, possibly

causing property damage, serious injury, or death.

Improper installation and/or operation will void the

warranty.

6.2.1 Blocked Impeller

WARNING

While servicing the pump, switch off the circuit

breakers at the power source. Severe personal injury

or death may occur if the pump starts while your hand

is inside the pump.

1.

Turn off the pump. Switch off the circuit breaker

to the pump motor.

2.

Remove the lid and basket.

3.

Look inside the pump for debris. Remove any

debris found inside.

4.

Replace the basket and lid.

5.

Switch on the circuit breaker to the pump motor.

6.

Turn on the pump, and see if the problem is

solved.

7.

If the impeller is still blocked with debris and it

is not possible to remove the debris using Steps 2

through 4, the pump will need to be disassembled

in order to access the inlet and outlet of the

impeller.

6.2.2 Impeller Removal

WARNING

While servicing the pump, switch off the circuit

breakers at the power source. Severe personal injury

or death may occur if the pump starts while your hand

is inside the pump.

1.

Turn off the pump. Switch off the circuit breaker

to the pump motor. If you are not replacing the

motor, do not disconnect the electrical wiring.

NOTE

If you are replacing the motor, Zodiac Pool Systems,

Inc. strongly recommends that a qualified service

technician or electrician properly disconnect the

electrical wiring at the pump motor.

2.

Turn off any valves to prevent pool water from

reaching the pump. Drain the water from the

pump by loosening the unions or removing the

drain plugs.

3.

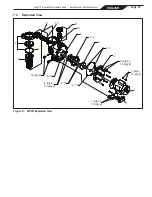

Using a 9/16" wrench, loosen the bolts

connecting the pump body to the motor

backplate. See Figure 3.

4.

Pull the motor and backplate out of the pump

body. Remove the pump body o-ring. The

impeller is connected to the motor shaft.

5.

Using a No. 1 Phillips screwdriver, remove the

two (2) screws holding the diffuser. (The diffuser

is the cover over the impeller). Then remove the

diffuser. See Figure 4.

6.

Remove any debris from the inlet and outlet of

the impeller.

Pump

Body

Motor Backplate

Bolts (8)

Motor Shaft Cover

Figure 3. Remove the Pump Housing

Содержание WFTR

Страница 2: ......

Страница 23: ...Page 23 ENGLISH Jandy Pro Series Water Feature Pump Installation and Operation Manual NOTES...