DCF-S-0126-2A (06.04)

Japan Aviation Electronics Industry, Ltd.

Connector Div. Production Engineering Dept.

日本航空電子工業株式会社コネクタ事業部生産技術部

Number

番号

T703580

Page

6

/

20

JAE Connector Div. Proprietary.

Copyright © 2020, Japan Aviation Electronics Industry, Ltd.

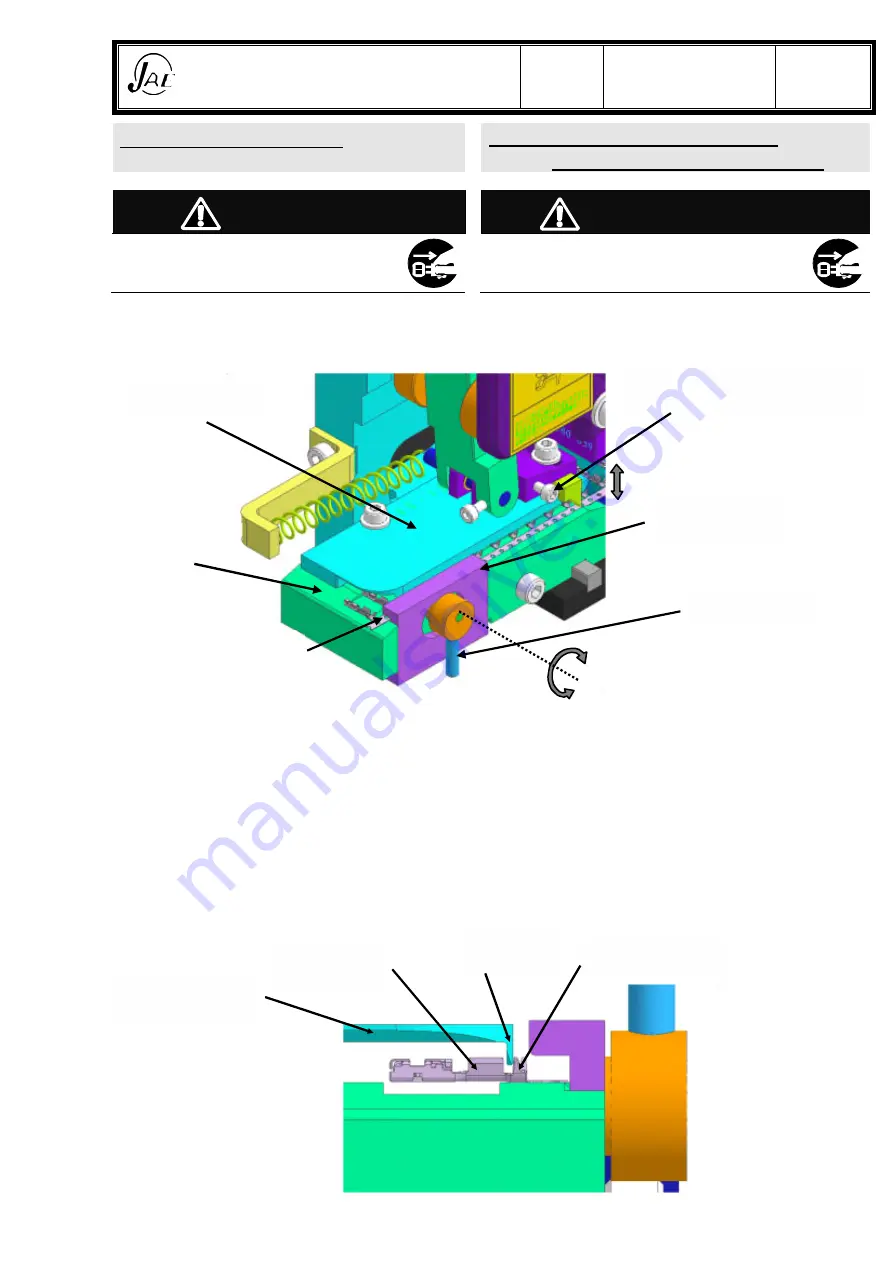

3.コンタクト挿入・取り外し

3.Attachment and Removal

of Contact into Applicator

注意

CAUTION

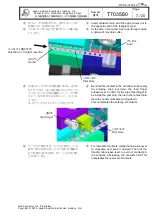

■アプリケータにコンタクトをセットする時、

又は取外す時は必ず電源プラグを抜いて下

さい。

■

In setting or removing contacts into the

applicator, disconnect the POWER plug from

the outlet.

①

操作レバーを上側に回して下さい。レバーが下

側に有る場合は時計方向に回して下さい。

①

Turn the operation lever of the lift cum unit

upward.If

the

lever

is

placed

below,

turn

clockwise.

②

この状態で送り爪外しレバーを持ち上げてコン

タクトを送り台カバーと送り台の間に挿入しま

す。

②

In this condition, remove the feed finger, and

then insert contacts between feed plate cover.

※

この時“手前側キャリアはコンタクト押えと送り台

の間に”又送り台カバーのガイド部が“コンタク

トの芯線バレルと被覆バレルの間に”入るように

して下さい。

※

At,that time, be sure to place the carrier between

“the contact hold and thecontact feed plate”.Also,

confirm that the guide of feed plate cover is

placed between “wire barrel of contact and the

insulation barrel”.

※

コンタクトはガイド部によって位置決めされてい

ます。

送り台カバーは不用意に取り外さないで下さ

い。

※

Contacts are guided for the location with the

location guide.

Do not remove the feed plate cover.

送り爪外しレバー

Lever for removal of feed finger

送り台カバー

Feed plate cover

コンタクト送り台

Contact feed plate

ガイド部

Guide

コンタクト押え

Contact Hold

操作レバー

Operation Lever

送り台カバー

Feed plate Cover

被覆バレル

Insulation barrel

芯線バレル

Wire barrel

ガイド部

Guide

6/20