M A I N T E N A NC E

Page 42

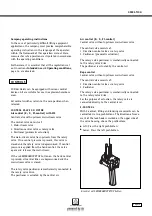

The motor and brake functions are achieved in part by

means of shared components. The braking action is

applied at the lateral surfaces of the rotor. The rotor is

pressed via spring force from the cover-side of the

motor against a second braking surface located on the

opposite side by means of a piston on which braking

material is bonded.

R E M O VA L

Proceed as follows when removing the motor

with the brake:

Disconnect the hoist from the main air supply.

Detach the control valve from the motor (in order to

permit removal of the motor retaining bolts).

Detach the motor from the hoist.

Remove the motor cover bolts

1

and remove the

motor cover

2

with the nameplate

3

. (When the cover

bolts are removed, brake spring tension

4

is fully

released).

Remove the springs.

Remove the brake piston

5

from the internal cylinder

integrated in the motor housing.

Pull out the rotor

6

, removing the vanes

7

and

starting aids

8

.

Note:

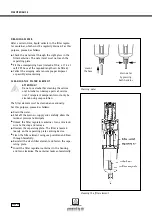

If you only wish to check for vane wear or repla-

ce the vanes with the starting aids, please continue

with the section "Checking for vane wear".

Remove the cover bolts

9

and pull out the cover with

the brake lining

10

.

Check the braking surfaces of the brake piston and

the cover with the brake lining for wear and damage,

replace if necessary. The circular wear pattern in the

braking surfaces must not be deeper than 0.2 mm.

The extremely low-wear braking material will not

reach the wear limit of 0.2 mm within the design-

dependent service life of the hoist, under intended use.

Should the wear limit be reached prematurely, the

actual compressed air pressure must be checked with

the device switched on (the brake drags in the event

of insufficient pressure).

Checking vane wear (see illustration

Checking vane

wear,

page 43). When the air motor vanes are worn,

the motor power and consequently the lifting perfor-

mance of the JDN Air Hoist are reduced. Replacing

the vanes together with the starting aids.

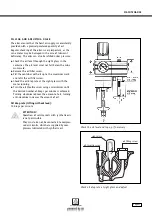

R E P L AC I N G B R A K E D I S C , B R A K E P I S T O N

A N D VA N E S / M O T O R I N S TA L L AT I O N /

M O T O R L U B R I C AT I O N

Replacing brake disc, brake piston and vanes /Motor installation

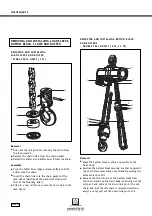

8

10

9

7 6

12 11 5

4

2

13/14

1

3

Содержание PROFI 10 Ti

Страница 1: ...J D N O P E R A T I O N M A N U A L A I R H O I S T S 16 10 6 3...

Страница 58: ...NOTES Page 58...