Oil pressure / temperature sensor

The body of the sensor is similar to that one of the air pres-

sure/temperature sensor and the functions carried out are

analogous. It is assembled onto the engine oil filter support,

to measure the engine oil temperature and pressure.The sig-

nal detected is sent to ECU EDC that manages low pressure

indicator light. In this appliance, pressure and oil temperature

values are not shown by instruments but the data are used

by ECU to carry out the monitoring functions. In order to

control oil pressure gauge on the instrument panel, a specif-

ic sensor is used.

It is connected to ECU EDC by pins A9, A19, A33 e A35

Pressure sensor is powered by a 5 V voltage and the out-

put voltage is proportional to the pressure detected. Tem-

perature sensor has a resistance of about 2.5 k

Ω

at 20 °C

temperature.

Crankshaft sensor

It is a variable reluctance inductive type, which generates peri-

odical alternate signal due to flow variation in the magnetic

circuit produced inside the cranckshaft by the presence of a

permanent magnet. It faces the pulley keyed on the crankshaft

to detect the passage of 58 tooths every revolution. The

number of 58 tooths has been derived by a constant pitch of

6° which would lead to a total of 60 tooths, 2 of which have

been eliminated to generate an asimmetry of the signal that

ECU EDC uses as crankshaft positioning reference.

The signal of this sensor is processed in ECU to assess:

-

Engine rotation speed

-

Engine crankshaft acceleration.

-

Angular position of the engine in respect to TDC (top

dead center) of the pair of pistons

It originates the information of the engine RPM on the

instrument and control panel.

The interruption of the signal of this sensor during engine

operation is provided by a “recovery” of ECU actuated using

the signal of the camshaft sensor, thus enabling engine to

carry on operating.

The solenoid is connected to terminal 1 and 2 and has a

resistance of about 900

Ω

. It is connected to ECU EDC by

pins A24 e A25.Terminal 3 is connected to electric shielding

and is insulated from sensor.

N60 ENT M37

OVERVIEW

1.45

APRIL 2004

04_062_N

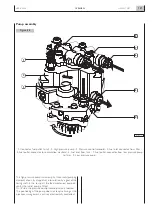

Figure 56

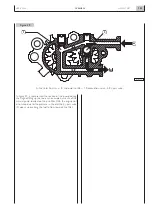

04_063_N

1

2

3

Figure 57

Содержание N60 ENT M37

Страница 1: ...NEF ENGINE N60 ENT M37 TECHNICAL AND REPAIR MANUAL T E C H N O L O G I C A L E X C E L L E N C E ...

Страница 4: ...N60 ENT M37 IV APRIL 2004 ...

Страница 52: ...N60 ENT M37 OVERVIEW 1 52 APRIL 2004 ...

Страница 54: ...N60 ENT M37 TECHNICAL DATA 2 54 APRIL 2004 ...

Страница 60: ...N60 ENT M37 TECHNICAL DATA 2 60 APRIL 2004 ...

Страница 62: ...N60 ENT M37 ELECTRICAL EQUIPMENT 3 62 APRIL 2004 ...

Страница 92: ...N60 ENT M37 DIAGNOSTICS 4 92 APRIL 2004 ...

Страница 116: ...N60 ENT M37 DIAGNOSTICS 4 116 APRIL 2004 ...

Страница 118: ...N60 ENT M37 MAINTENANCE 5 118 APRIL 2004 ...

Страница 122: ...N60 ENT M37 MAINTENANCE 5 122 APRIL 2004 ...

Страница 124: ...N60 ENT M37 SERVICING OPERATIONS ON INSTALLED ENGINE 6 124 APRIL 2004 ...

Страница 139: ...SECTION 7 TOOLS Page TOOLS 141 N60 ENT M37 TOOLS 7 139 APRIL 2004 ...

Страница 140: ...N60 ENT M37 TOOLS 7 140 APRIL 2004 ...

Страница 146: ...N60 ENT M37 TOOLS 7 146 APRIL 2004 ...

Страница 156: ...APRIL 2004 OVERHAUL 8 156 N60 ENT M37 ...

Страница 164: ...APRIL 2004 OVERHAUL 8 164 N60 ENT M37 ...

Страница 181: ...OVERHAUL APRIL 2004 N60 ENT M37 8 181 ...

Страница 188: ...N60 ENT M37 OVERHAUL 8 188 APRIL 2004 ...

Страница 190: ...N60 ENT M37 SAFETY PRESCRIPTIONS 9 190 APRIL 2004 ...

Страница 193: ......