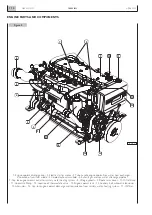

NEF engines are the highest expression of design and engi-

neering efficiency that IVECO MOTORS makes available on

the market place. Engines highly innovative designed to be

able to comply now with the regulations on fumes and

acoustic emissions that will be enforced in the near future.

As designed by innovative techniques and manufactured by

advanced working processes,they are the result of hundred

years of design and engineering tradition as well as of an

important international cooperation.

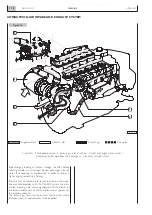

The excellent performance of NEF engines originates from

induction and exhaust ducts of new design where, by

improving the gas exchange phases, the intaken air turbo-

lence is improved, thus enabling the complete exploitation of

the new injection system capacity.

The new criteria chosen in defining the parameters setting

the combustion conditions, metering and injection, optimized

instant by instant, enable to obtain new balance between

high performance and consumption reduction. NEF engines

can be rigged by a mechanical pump or by a total electronic

controlled “Common Rail” fuel supply system.

Every technical solution has been accurately devised so as to

assure qualitative product perfection.The configuration istself

of the engine has been designed in such a way so as to facil-

itate access to each individual part and thus reducing main-

tenance time.

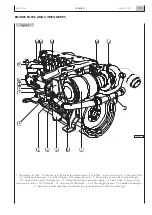

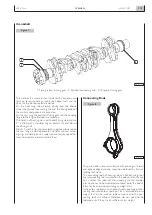

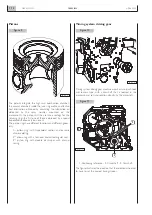

The cylinder head fitted with four valves per cylinder, rear

timing control, new design connecting rods and aluminum-

nickel pistons are components of an engine fitted with 40%

less elements of an engine of equivalent performance.

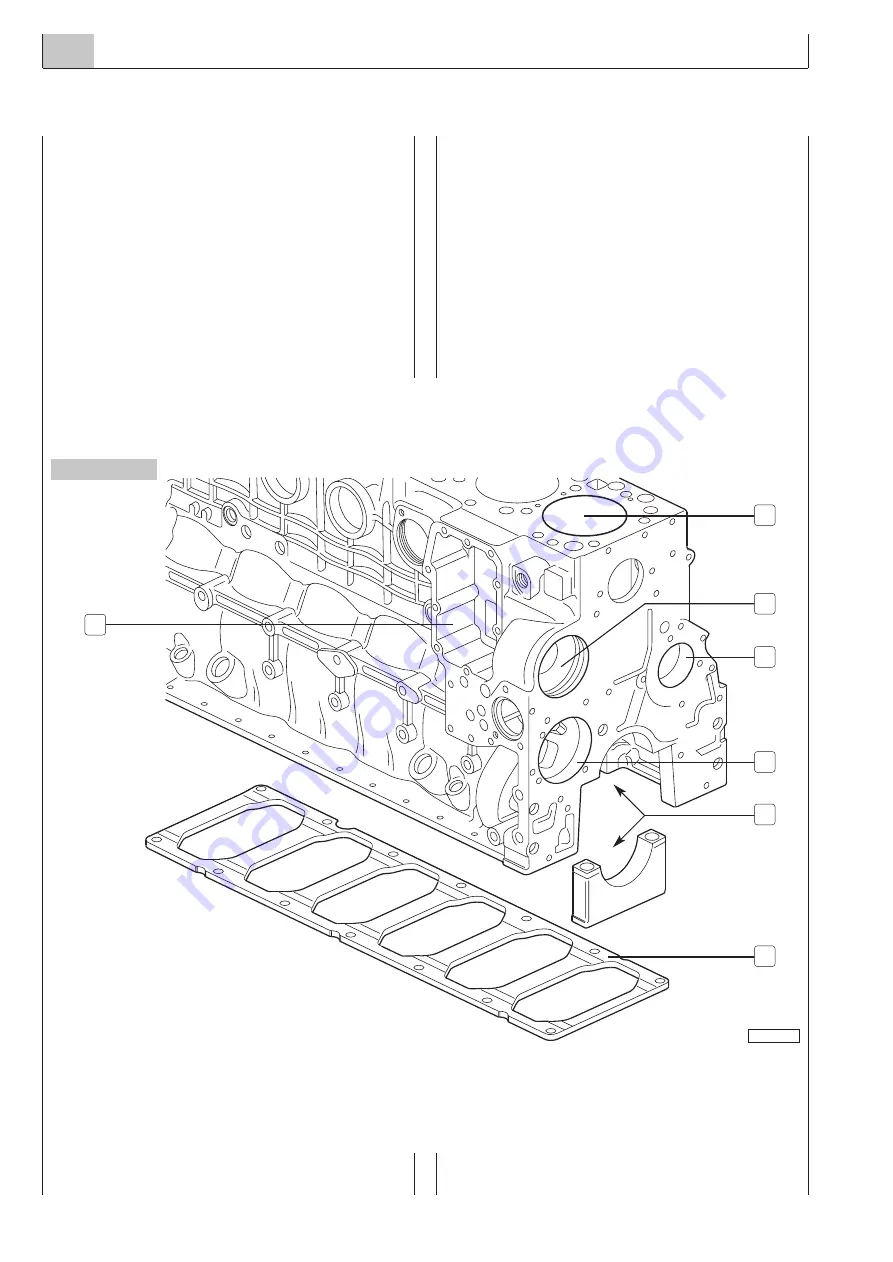

Moreover within the crankcase, made in cast iron, coolant

circulation grooves, ducts for lubrication loop for the various

machine members and the seating for push rod bushings

have been grooved in. The backing plate (6) applied to the

lower part, makes the crankcase stiffer and improves stress

strength.

N60 ENT M37

OVERVIEW

1.12

APRIL 2004

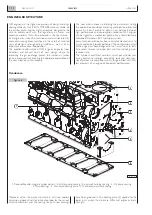

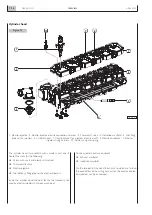

Crankcase

Figure 6

04_011_N

7

1

3

6

5

4

2

1. Reconditionable integral cylinder barrels - 2. Water pump seating - 3. camshaft bushing seating - 4. Oil pump seating -

5. Main bearings - 6. Crankcase backing plate - 7. Oil cooler (water/oil) seating.

ENGINE ARCHITECTURE

Содержание N60 ENT M37

Страница 1: ...NEF ENGINE N60 ENT M37 TECHNICAL AND REPAIR MANUAL T E C H N O L O G I C A L E X C E L L E N C E ...

Страница 4: ...N60 ENT M37 IV APRIL 2004 ...

Страница 52: ...N60 ENT M37 OVERVIEW 1 52 APRIL 2004 ...

Страница 54: ...N60 ENT M37 TECHNICAL DATA 2 54 APRIL 2004 ...

Страница 60: ...N60 ENT M37 TECHNICAL DATA 2 60 APRIL 2004 ...

Страница 62: ...N60 ENT M37 ELECTRICAL EQUIPMENT 3 62 APRIL 2004 ...

Страница 92: ...N60 ENT M37 DIAGNOSTICS 4 92 APRIL 2004 ...

Страница 116: ...N60 ENT M37 DIAGNOSTICS 4 116 APRIL 2004 ...

Страница 118: ...N60 ENT M37 MAINTENANCE 5 118 APRIL 2004 ...

Страница 122: ...N60 ENT M37 MAINTENANCE 5 122 APRIL 2004 ...

Страница 124: ...N60 ENT M37 SERVICING OPERATIONS ON INSTALLED ENGINE 6 124 APRIL 2004 ...

Страница 139: ...SECTION 7 TOOLS Page TOOLS 141 N60 ENT M37 TOOLS 7 139 APRIL 2004 ...

Страница 140: ...N60 ENT M37 TOOLS 7 140 APRIL 2004 ...

Страница 146: ...N60 ENT M37 TOOLS 7 146 APRIL 2004 ...

Страница 156: ...APRIL 2004 OVERHAUL 8 156 N60 ENT M37 ...

Страница 164: ...APRIL 2004 OVERHAUL 8 164 N60 ENT M37 ...

Страница 181: ...OVERHAUL APRIL 2004 N60 ENT M37 8 181 ...

Страница 188: ...N60 ENT M37 OVERHAUL 8 188 APRIL 2004 ...

Страница 190: ...N60 ENT M37 SAFETY PRESCRIPTIONS 9 190 APRIL 2004 ...

Страница 193: ......