Page 9

Operation and maintenance instructions

Envistar / CRAMO

DSCR111125.01

Air handling with the focus on LCC

SV

EN

DA

FI

NO

Continuous product development may give rise to specification changes without prior notice.

Inspection

1. Switch off the unit from the micro terminal and lock the safety switch in the 0 posi-

tion.

2. Wait until the fans have stopped rotating, and then open the inspection door.

WARNING!

Positive pressure inside the unit, risk of personal injury. Wait and

allow the pressure to drop before you open the inspection doors.

3. Check that the rotor rotates easily. If it turns sluggishly, you may have to adjust

the position of the bristled seals.

4. Make sure that the bristles of the bristled seal on the rotor are against the side

plates, and that they are not worn. The bristles of the seal are subject to wear

and therefore should be occasionally adjusted or replaced when the need

arises.

5. Check that the drive belt is properly tensioned and does not slip. If the belt slips,

it will have to be shortened. The speed of the rotor should be at least 8 r/min for

full heat recovery.

6. Check that the drive belt is undamaged and clean.

7. Check that the air inlet surfaces of the rotor are not coated with dust or other im-

purities. N.B! Avoid touching the inlet and outlet surfaces of the rotor with your

hands or tools.

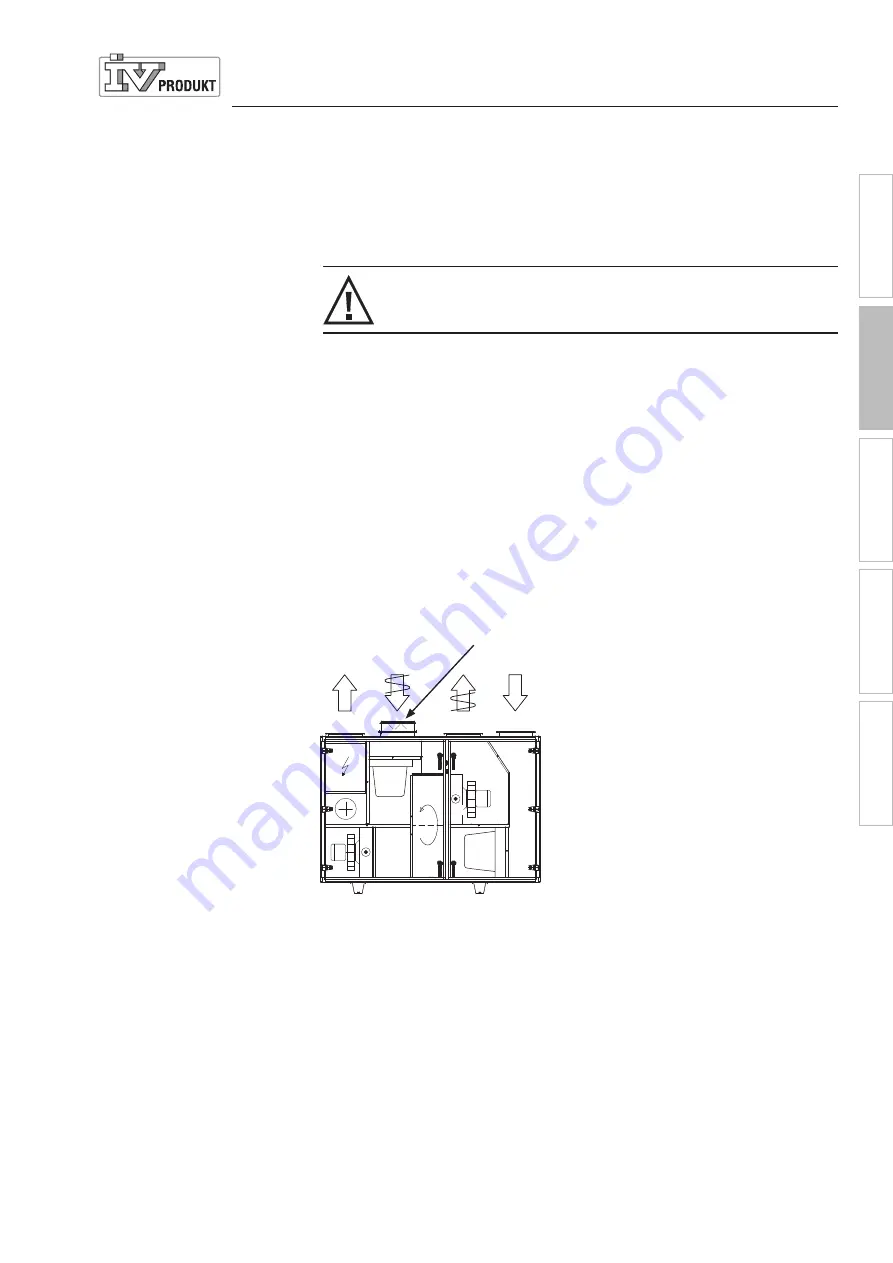

8. Check the pressure balance. See the illustration below.

P1

P4

P3

P2

ETET-TR

To check the pressure balance

To ensure correct function of the purging sector, the negative pressure at P3 should be

greater than that at P2. If this is not the case, you can use an ESET-TR trim damper on

the extract air side to throttle the airflow and establish correct pressure balance.

Cleaning

Carefully vacuum clean with a soft brush nozzle. If the surfaces are substantially

fouled or are coated with greasy impurities, the rotor can be sprayed with water

mixed with dishwashing detergent ( of a type that will not corrode aluminium).

Compressed air sprayed at low pressure (max 6 bar) can be used for blowing

surfaces clean. Do not hold the nozzle closer to the rotor than 5 – 10 mm.

Lubrication

The bearings and drive motor are permanently greased and require no lubrication.