Step 12 - Test Print

Goal:

Verify communications between the applicator and the printer

Goal:

Optimize the printer image offset on the label, print darkness, presentation of the label out of

the printer (pitch), and print quality.

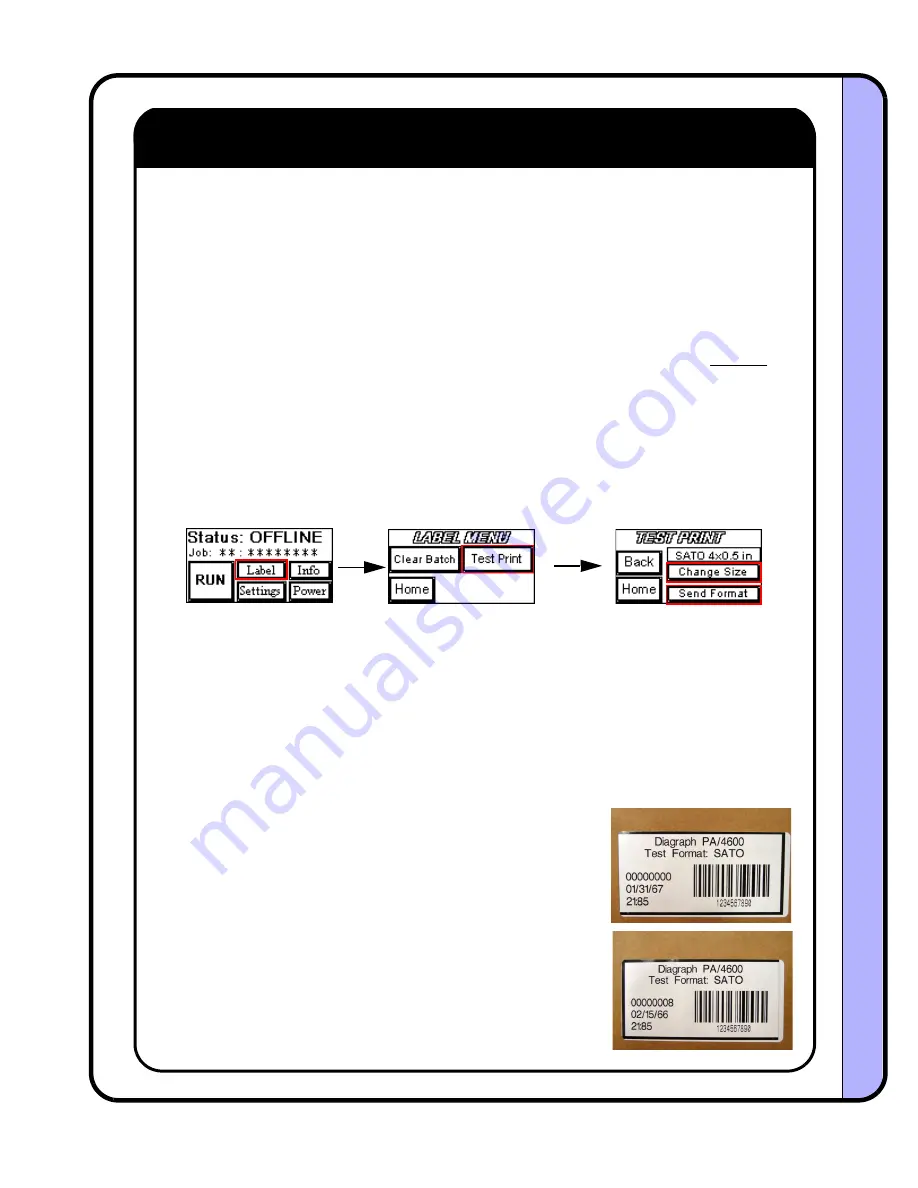

•••• Sub-Step (a) ••••

Begin by setting the desired baud rate in the printer, and in the PA/4600 or PA/6000. Typically,

applications run well at 19,200 baud since this rate allows more immunity to signal noise and can

allow greater cable distances. For applications that demand higher throughput, higher serial speeds or

Ethernet may be required. Select the baud rate for the system from the menu seen on

•••• Sub-Step (b) ••••

Send a test print format to the printer by entering the Label Menu and select Test Print. Select the

correct label format size to send by pressing the Change Size button. The format choices are for fixed

sizes, but other label sizes will work with these as well, just use the test print size smaller than the

actual label length. Label widths smaller than 4 inches can be used, but some of the format

information will not be seen on the label.

Map:

The format contains some sample text, barcode, incrementing 8 digit counter, a time and date stamp,

and a box border. If the printer is not equipped with a time/date clock option, the information in these

fields will be some default text.

•••• Sub-Step (c) ••••

After selecting the correct format size and printer option, press the Send Format button. If the printer

does not show a batch quantity on its display, or if there is a Framing Error, the baud rate is incorrect

or the cabling to the printer has a problem. Once the quantity is displayed, press Run from the home

screen to print the label.

•••• Sub-Step (d) ••••

Make corrections to the print based on the results of the test print. On

the right, the top label is shown with a vertical and horizontal offset of

0,0. Correct the image presentation on the format by using the printer

menu selection of Print Offset. The bottom label shows the change in

print, once the horizontal offset was set to 10mm. Notice that the right

border is now visible on the corrected label (bottom view).

Other adjustments made through the printer include: print darkness,

label pitch, print speed, and time/date setting. Once the test label

looks centered and clear, proceed to the next step.

Image shifted left

Image corrected to right

Diagraph - an ITW Company PA/4600 & PA/6000 User Manual

Setup

Page 22

Setup

Содержание Diagraph PA/4600

Страница 1: ...PA 4600 PA 4600 PRINTER APPLICATOR PRINTER APPLICATOR PA 6000 PA 6000 4600 010 Revision G ...

Страница 47: ...Diagraph an ITW Company PA 4600 PA 6000 User Manual Maintenance Page 46 Maintenance ...

Страница 48: ...Diagraph an ITW Company PA 4600 PA 6000 User Manual Maintenance Page 47 Maintenance ...

Страница 49: ...Diagraph an ITW Company PA 4600 PA 6000 User Manual Maintenance Page 48 Maintenance ...