5

D

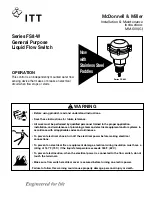

FLUID FLOW

D= PIPE DIAMETER

1" PIPE

CONNECTION

5 x D

MINIMUM

5 x D

MINIMUM

a.

The flow switch must be installed in the pipe using

a threaded tee connection or welding fitting of

minimum length such as a half coupling. Use a

face or hex bushing to reduce the tee outlet to 1"

pipe thread if a reduced tee outlet thread size fitting

is not available.

1

" MAX

(25mm)

Paddle Arm

b.

When installing brazed/soldered copper pipe,

size the threaded adapter to ensure the paddle

arm extends into the main run of the pipe.

• The flow switch

should be located in a horizontal

section of pipe

where there is a straight horizontal

run of at least 5 pipe diameters on each side of the

flow switch. The flow switch may be installed in a

vertical pipe if the flow is in the upward direction.

• The flow switch

must be installed in the upright

position

as shown with arrow mark on side of casting

in the same direction as fluid will flow.

• Some system conditions that require more than 5 pipe

diameters are high viscosity fluid and high fluid velocity.

• The flow switch must be installed in the pump suction

piping when spring-loaded check valves and/or other

close coupled accessories are installed in the pump

discharge piping.

1" (25mm)

1"

(25mm)

1"

(25mm)

1" (25mm)

2

"

(50mm)

1

1

/

4

"

(32mm)

1

1

/

2

"

(40mm)

1

1

/

4

"

(32mm)

2

"

(50mm)

1

1

/

2

"

(40mm)

FACE OR HEX.

BUSHING

2

" (50mm)

3

"

(80mm)

2

" (50mm)

3

"

(80mm)

1

1

/

4

" (32mm)

1

1

/

4

" (32mm)

1

1

/

2

" (40mm)

1

1

/

2

" (40mm)

2

1

/

2

"

(65mm) 2

1

/

2

"

(65mm)

2

" (50mm)

3

" (80mm)

1

" MAX

(25mm)

1

" (25mm)

4

" (100mm)

6

" (150mm)

2

" (50mm)

3

" (80mm)

4

"

(100mm)

6

"

(150mm)

2

1

/

2

"

(65mm)

2

1

/

2

" (65mm)

Threaded

Pipe

Threaded

Pipe

CORRECT

INCORRECT

Threaded

Pipe

Welded

Pipe

STEP 2 - Determine the Location of the Flow Switch

STEP 3 - Connecting the Flow Switch to Pipe

a.

Insert the 8/32 x 5/16" screw through lock washer, new larger

washer and paddle. Attach screw to the paddle arm and tighten

to a torque of approximately 12-16 lb•in (1.36-1.81 N•m).

NOTE: If two paddles are being installed, they must be stacked one on top

of the other with the longer paddle first in line to the flow.