24

SLS-SLH 10/06

Faulty

Probable cause

Remedy

AL00

See the alarm

Autoreset

Automatic alarm

intervention

AL01

Wrong compressors rotation

To check the electrical connection

Wrong power supply

AL02

Low water flow

To check the pump

Antifreezing

Wrong pump

To check the pump size

Water filter dirty

To clean the filter

Dirty exchanger

To clean the exchanger

High circuit pressure drop

To check the plant pressure drop

AL03

External interlock contact open

To check the electrical connection

Interlock

To check the interlock external contact

AL04

Water pump stop

To check the pump

Luck of flow

Water pump blocked

To release the pump

Pump thermal contact open

To reset the thermal contact and to check

the scale

Flow switch blocked

To release the flow switch

AL05

Espansion valve broken

To replace the espansion valve

Sys 1

Gas circuit empty

To charge the circuit

Low pressure

Gas leak

To find and repair the leak

High temperature water inlet

To check the plant thermal load

Solenoid valve not open

To check the electrical connection

Solenoid valve not open

To check Pump Down setting

AL06

Espansion valve broken

To replace the espansion valve

Sys 2

Gas circuit empty

To charge the circuit

Low pressure

Gas leak

To find and repair the leak

High temperature water inlet

To check the plant thermal load

Solenoid valve not open

To check the electrical connection

Solenoid valve not open

To check Pump Down setting

It is a Simultaneous Global Defrost.

Parameters used: Defrost start Temp; Defrost stop temp,

defrost Delay time, defrost Max time, Reversing Off

Time. It is possible to set compressor switch off time

(Reversing Off parameter) when system enter and exit

from defrost mode. Compressors are not switched off if

time is set to 0 seconds. Moreover cycle reversion dur-

ing normal operation (changing from summer to winter

mode or back) always follow compressors switch off.

If one of the two Tcoil probes temperature values fall

below the Defrost start Temp, a timer starts. The timer is

increased while the Tcoil value is under the Defrost start

Temp. When the timer (t1 + t2 + t3 + …) reaches the

defrost start time value, the defrost cycle starts for both

system.

During defrost cycle, fans are stopped, all compressors

run (if one or more are in off, they must be powered),

reverse valve is powered.

During defrost cycle, if the discharge pressure in one of

the two systems, reaches an high dangerous value, fans

must run at max speed. So, if discharge pressure trans-

ducer are attached, if one of the two high pressure val-

ues reaches the Max Discharge Pressure value (see

MDP) the fans contactor is energized and the analogue

output is forced to 5Vdc. If High Pressure Transducer

are not attached, in HeatPump there will be a High

Pressure Switch each system, connected to the J1-1 and

J1-3. If during defrost, one of these pressure switch con-

tact closes, the fans will run at max speed.

Defrost cycle stops when the Tcoil value rises up to the

Defrost Stop Temp value, anyway if the Defrost Max

Time has elapsed.

When defrost cycle is ended, the reverse valve is un-

powered and fans are powered again, according to

fans rule logic.

17

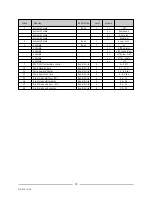

SLS-SLH TROUBLE SHOOTING

The following table details possible unit faults, their probable cause and suggested remedies, for any other problems

not immediately recognisable and/or technical assistance, call an authorised Technical Service Center.