23

SLS/SLH 10/06

13

OIL RECOVERY FUNCTION

If one of the compressor (circuit 1-2) running at 50%

more than 40’ the control will force the the compressor

(circuit 1-2) at 100% for 5 minuts.

14

PUMP CONTROL

Parameters used in Pump management mask: Remote

logic, Stand-by, Delay Stop.

Pump always starts 30 seconds before the first compres-

sor is loaded and stops always a parameter Pump

Delay Time value in seconds after the unit is stopped

locally or by remote start/stop digital input.

If the parameter “Pump Remote Logic” is in YES, if the

unit is stopped by the remote Start/Stop digital input,

the pump continues to run. It only stops if the unit is

locally stopped by panel.

When the unit is in Off, always pump runs for 5 mins

every “Pump Stand-by Interval” value, setted in Service

Level. Default must be 12 hours.

If the pump is not controlled by the electronic control put

the stand by value at 00.

If the unit is in stand-by, the pump must anyway be start-

ed if the Antifreeze heater is powered or the unit is in

Antifreeze alarm.

15

PUMP-DOWN LOGIC – LIQUID

LINE SOLENOID VALVE

CONTROL

Pump Down during start-up of the first compressor of

each system and during stop of the last compressor of

each system.

Parameters used: Pump-Down Max Time, Pump-Down

Enable, Liquid Line Solenoid Valve Enable. All the fol-

lowing logic is valid only if Liquid Line Valve are select-

ed as present in Factory Level, and if Pump-Down is

enable in Service Level.

Each system is equipped with one liquid line solenoid

valve, to feature a pumping down.

Pump-down finishes by low pressure, when Low Pressure

Switch opens and/or by maximum time reached. See

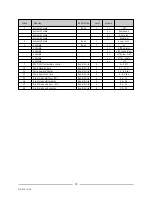

the mask and graphs below for further information.

16

DEFROST CYCLE

(HEAT PUMPS ONLY)

Defrosting of a circuit with time/temperature control: