4

Section

3

ASSEMBLY,LUBRICATION,

INSTALLATION

Note:

These instructions must be followed to insure proper

installation, efficient operation and the prevention

of serious damage to your stitcher.

Before Unpacking:

Examine the outside of the crate or carton for any

visible damage. If damaged DO NOT UNPACK

THE STITCHER. Notify the carrier who deliv-

ered the stitcher.

After Unpacking:

Examine your stitcher carefully for any damage in

transit. If damaged, DO NOT INSTALL THE

STITCHER. Notify your nearest representative and

the carrier who delivered your stitcher.

Make certain that you get a signed copy of the

Carrier Inspectors Report of the damage incurred.

ASSEMBLY

1. Clamp or bolt the M2000 head to your machine

2. Install Wire Guide Spring into wire guide

bracket of M2000 Head.

THREADING WIRE AND

ADJUSTING WIRE

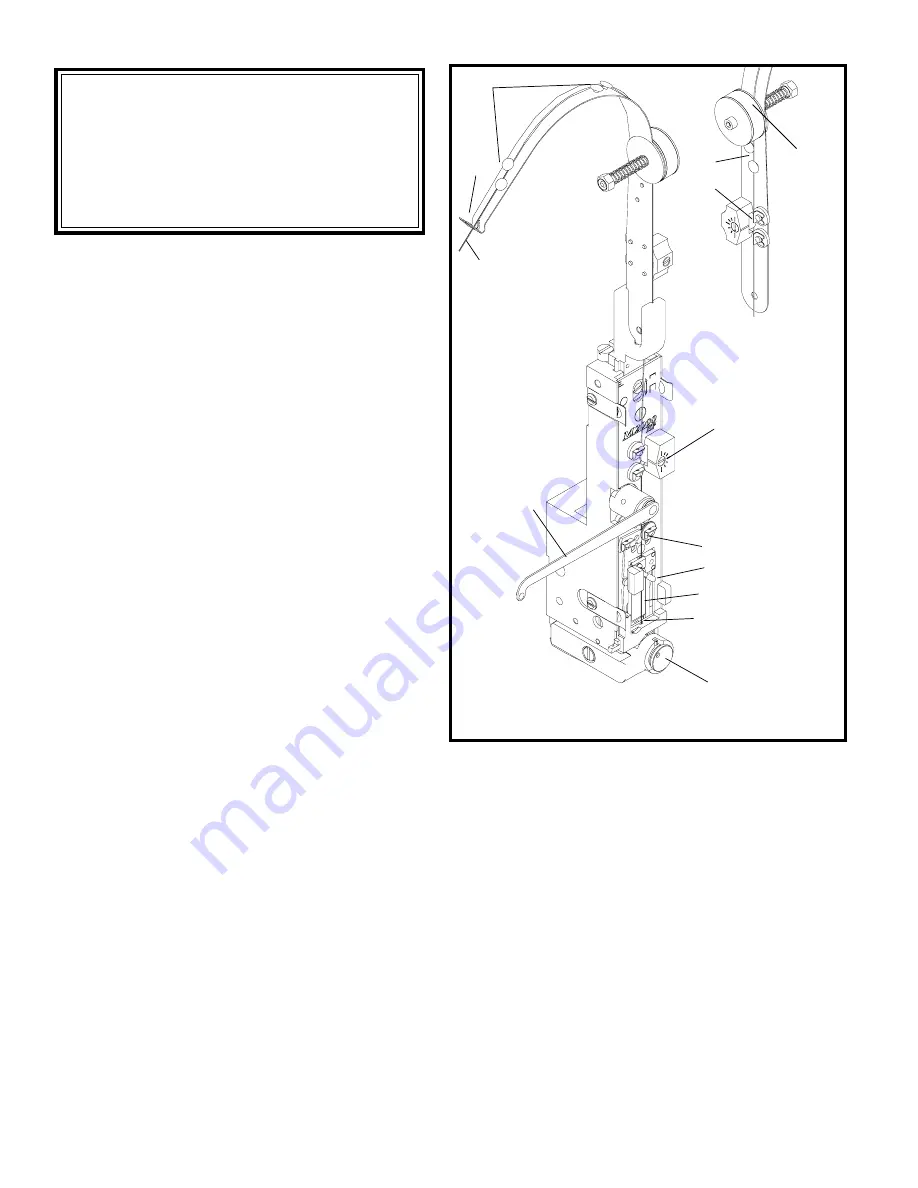

STRAIGHTENERS (See fig. 1)

1. Draw wire (Index A) by hand, from the coil.

2. Thread the wire through the slot (Index B) at

the end of the wire guide spring, , through the

wire guides (Index C), between the thin and

thick felt wire wipes (Index D), through the

upper wire straightener (Index E), and through

the lower wire straightener (Index F).

A (From wire coil)

C

H

G

J

K

F

B

C

E

3. Release the rotator operating spring (Index H)

from the rotator and swing it to the left.

Remove Rotator (Index K).

4. Thread the wire between the tension pawl and

tension roll (Index G). Feed the wire through

the wire cutter lead-in hole (Index I) in the

bottom of the face plate.

5. Push grip post to left to open the grip (Index J).

Insert wire and release the post so that the grip

engages the wire for feeding into the rotator.

6. To check adjustment, hold open grip (Index J

and pull about 1 1\2 feet of wire from below

face plate. Cycle machine once by hand to cut

wire. Cycle machine again by hand to observe

wire straightness. The wire (Index L) should

point straight down, prior to being cut.

I

(CTTT2605 Scene 3, Scene 4)

Figure 1

D

L