8

A

C

D

E

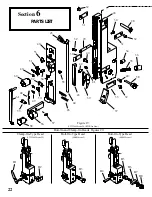

Section

5

MAINTENANCE,TROUBLE

SHOOTING AND

ADJUSTMENTS

General

The M2000 Stitcher is a friction-type head which

depends on smooth sliding friction and proper tim-

ing to function correctly. Preventative maintenance

will go far to insure trouble-free operation. Avoid

production down time by keeping your stitcher lu-

bricated and in top working condition at all times.

Recommended Spare Parts

Like any equipment that has moving parts, certain

parts of your stitcher will be subjected to more

wear than others and require replacement. The fol-

lowing listing includes all the parts required for

minimum maintenance and good operation.

PART NAME

QTY.

Wire Cutters

2

Grip

1

Grip Spring

1

Tension Roll Clip

2

Rotator

1

Clincher Points

2

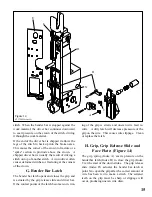

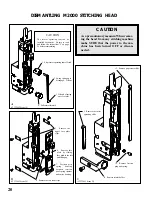

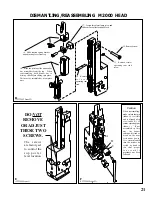

Caution

MAKE ALL ADJUSTMENTS

WITH THE POWER OFF AND

THE STITCHING HEAD IN

NEUTRAL POSITION! (Fig. 6)

In neutral position, the wire grip assem-

bly (Index A) is stopped at the top of the

slot in the face plate.

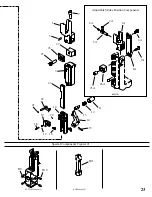

Stitching Adjustments

Best stitching performance will be assured if all

adjustments are made so that you get the following

results:

1. Good Cut-Off

2. Uniform Wire Draw

3. Equal Leg Length

4. Proper Clincher Alignment

5. Sufficient Compression

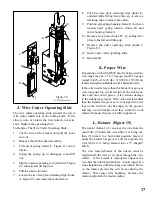

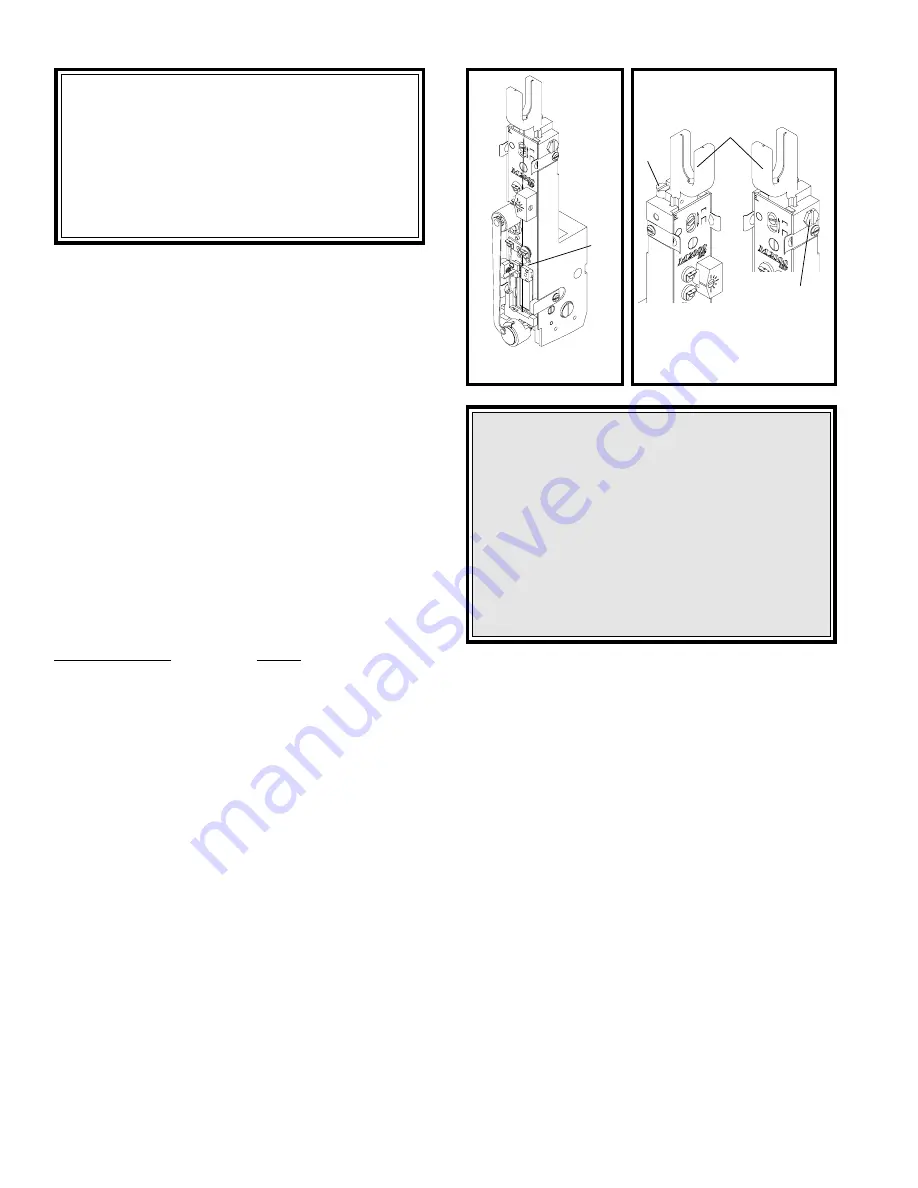

To Equalize Both Legs of Stitch

(Figure 7)

1. Loosen the wire guide locking bolt (Index C).

2. Turn adjusting screw (Index D) clockwise to

shorten left leg of stitch; counter clockwise to

lengthen left leg.

3. Tap bracket (Index E) down before tightening

screw (Index C).

(CTTT22605 Scenes 5 & 9)

(CTTT2605 Scene 8)

Figure 6

Figure 7