441 01 2613 05

19

Specifications are subject to change without notice

3. Use black iron or steel pipe and fittings or other pipe approved

by local code.

4. Use pipe thread compound which is resistant to natural and

Propane gases.

5. Use ground joint unions and install a drip leg no less than 3

″

(76.2mm) long to trap dirt and moisture before it can enter gas

valve inside furnace.

6. Provide a

1

/

8

″

NPT plugged tapping for test gauge connection

immediately up stream of gas supply connection to furnace.

7. Use two pipe wrenches when making connections to prevent

furnace gas valve from turning.

NOTE: If local codes allow the use of a flexible gas appliance

connector, always use a new listed connector. Do not use a

connector which has previously served another gas appliance.

8. Flexible corrugated metal gas connector may

NOT

be used

inside the furnace or be secured or supported by the furnace

or ductwork.

9. Properly size gas pipe to handle combined appliance load or

run gas pipe directly from gas meter or Propane gas regulator.

10. Install correct pipe size for run length and furnace rating.

11. Measure pipe length from gas meter or Propane second

stage regulator to determine gas pipe size.

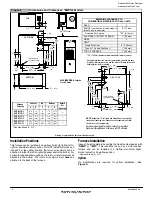

Right Side Gas Supply Piping (N8MP)

Gas line can be installed directly to the gas valve through the hole

provided in the right side of the cabinet. See

Figure 12

Left Side Gas Supply Piping (N8MP)

Two(2) 90

°

street elbows or two(2) 90

°

standard elbows and

two(2) close nipples are required for left side gas supply. See

Figure 12.

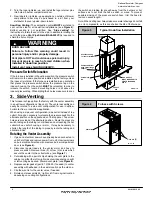

Piping with Street Elbows

1. Assemble the elbows so that the outlet of one(1) elbow is 90

°

from the inlet of the other. The elbows should be tight enough

to be leak proof. An additional

1

/

4

turn will be required at the

end of step 2, see

Figure 13

.

Figure 13

25

!

23

!

23c

Elbows (N8MP)

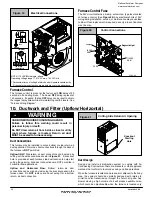

2. Screw elbow assembly into gas valve far enough to be leak

proof. Position elbow assembly so that the inlet of the elbow is

at the top of the gas valve. An additional

3

/

8

turn will be

required in step 3. Turn open end of inlet elbow to face the left

side of the furnace (

1

/

4

turn), see

Figure 14

.

Figure 14

Gas Valve with Elbows (N8MP)

Representative drawing only, some models may vary in appearance.

3. Turn assembly an additional

3

/

8

turn to position inlet near the

bottom back corner of the gas valve in line with gas opening

on left side of furnace, see

Figure 15

.

4. Gas supply line then can be run directly into opening of elbow.

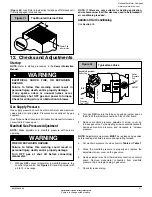

Piping with Close Nipples and Standard Elbows

1. Assemble elbows and nipples similar to street elbows shown

in

Figure 13

.

2. Follow steps 2 through 4

Piping with Street Elbows.

Figure 15

Gas Valve with Elbows (N8MP)

Representative drawing only, some models may vary in appearance.

FIRE HAZARD

Failure to follow this warning could result in

personal injury, or death, and/or property damage.

Use wrench to hold furnace gas valve when turning

elbows and gas line to prevent damage to the gas

valve and furnace.

!

WARNING

Left Side Gas Entry (*8MP) (See Figure 16)

Pipe can be run directly to gas valve through the hole provided in

the left side of the cabinet.

Right Side Gas Entry (*8MP) (See Figure 16)

Two (2) 90

°

street elbows or two (2) 90

°

standard elbows and two

(2) close nipples are required for right side gas supply,.

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.