22

Intermec EasyCoder 201 II – Technical Manual

SETUP PARAMETERS, cont'd.

Continued!

Detection

• LSS Adjustment

• Feed Adjustment

The Label Stop Sensor is situated immediately behind the printhead.

The Detection facilities are used to adjust the label stop or black

mark sensor (LSS) and to control the paper feed.

LSS Adjustment

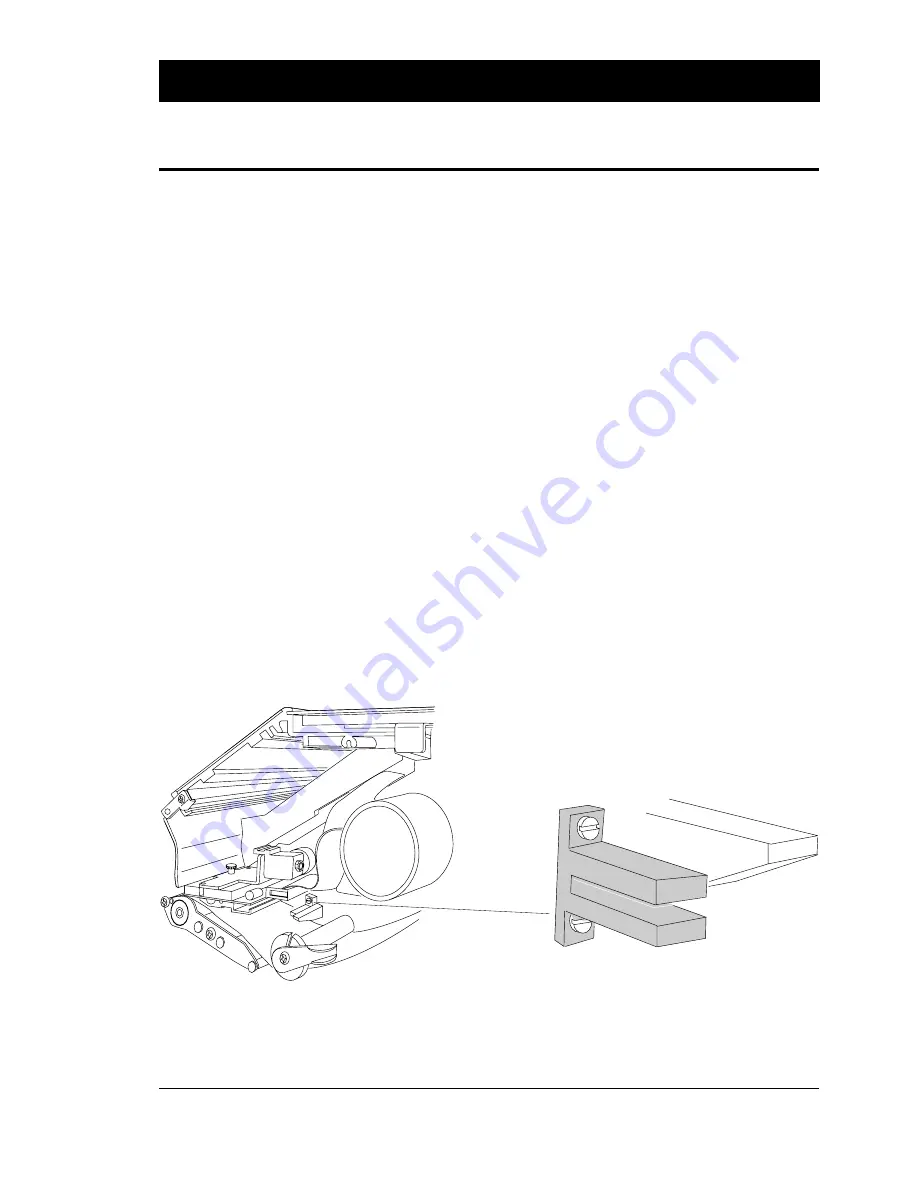

The LSS is a photo-electric detection device that controls the paper

feed. Situated inside the printing mechanism, it detects the front

edges of the labels or slits in tickets or tags.

As an option on some non-dispensing models, the Label Stop

Sensor can be replaced by a Black Mark Sensor (BMS), that detects

black marks printed either on the backside or the topside of tickets

or paper strip.

It is most important that the sensor is properly adjusted in regard to

sensitivity, so it can detect the difference between non-transparent

paper, semi-transparent backing paper (if any), the total absence of

paper (i.e. a ticket detection slit, and an out-of-paper condition), or

– in case of Black Mark Sensor – the difference in regard of

reflectivity between the paper web and the black mark.

If the printer works as expected, there is no need to adjust the label

stop sensor, but if the printer starts to feed out labels or tickets in an

unexpected manner, check that the paper web passes between the

two legs of the fork-shaped sensor and that the sensor has not

become dirty or blocked. Perform a few Testfeed operations to

allow the sensor to auto-adjust itself. If the error remains, proceed

according to the description of the Setup Mode for the printer model

in question.