3 Electrical Connection

Consider static electricity instructions (ESD)! See point 2.

•

The technical requirements and regulations for wiring, electrical security, as well as project specific

and environmental and local conditions etc. must be observed when mounting.

•

Avoid any influence of external interferences by using shielded cables for the bus line, but do not

connect the shield.

•

When selecting and installing the cables you have to comply with the regulations concerning the

RS-485 bus installation. The installations have to be executed in line topology. Cable length and

type have to be considered as well.

•

Strip the cables as short as possible. It is important to ensure that bare wires, e.g. wire shields do not

come into contact with the mounted PCB (risk of short-circuit).

•

Recommended cable for field bus: J-Y(St)Y 2x2x0.8 LG (20 AWG) min 300V, loop resistance 73

/km

(20.8

/1000 ft).

•

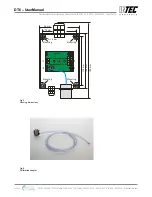

Recommended cable for local bus (remote mounting): J-Y(St)Y 2x2x0.8 LG (20 AWG), min 300 V.

•

Use Copper conductors only if the terminal is only for connection to copper wire.

3.1 Wire Connection

•

Open the cover.

•

Insert the field bus cable from above and connect it.

•

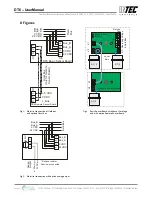

Remove terminal block X4 from BSB, connect cable according to connection diagram fig. 1.

•

Replug terminal carefully on the BSB at X4.

•

For remote sensor:

▪

Insert and connect local bus cable at the basic and remote sensor board.

▪

Remove terminal block X7 at sensor board, connect cable acc. to connection diagram fig. 1.

▪

Replug terminals carefully on both sensor boards.

•

Close cover.

Connecting the 24 V field bus voltage to the local bus terminal X7 can destroy the

DT6

Basic Sensor Board completely!

4 Commissioning

Only trained technicians should perform the following when commissioning:

•

Check for correct mounting location.

•

Check that the

DT6

board is firmly seated in the housing.

•

Check if connection is correct according to connection diagram.

•

Check power voltage.

•

Install the

SC2

Sensor Cartridge(s) if not already installed ex works.

•

Check

SC2

Sensor Cartridge connector for correct engagement.

•

Address the

DT6

Basic Sensor Board (BSB).

•

Register the

SC2

Sensor Cartridge(s) at the

DT6

BSB.

•

Calibrate (if not already factory-calibrated).

Required instruments for commissioning (calibration):

•

Service Tool STL6 or

•

DPT6

incl. EasyConfig

Software

and

USB/RS-485 communication set:

•

Calibration: See

SC2

user manual.

INTEC Controls | 12700 Stowe Drive, Suite 100, Poway, CA 92064 | Ph: (858) 578.7887 & (888) GO.INTEC | inteccontrols.com

Specifications subject to change without notice. | GASB2_03_E_0220 | USA 200306 | Page 5 of 15

DT6 – UserManual