Table 1. Sampling tubes recommended for different

duct widths:

Outside Duct Width

Sampling Tube Recommended*

1 to 2 ft.

ST-1.5

2 to 4 ft.

ST-3

4 to 8 ft.

ST-5

8 to 12 ft.

ST-10

*Must extend a minimum of two-thirds the duct width.

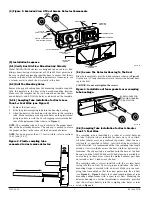

[5.4.1] Installation For Ducts Greater Than 1

1

⁄

2

Feet

But Less Than 8 Feet Wide

1.

If the tube is longer than the width of the air duct

, drill a 3⁄4”

hole in the duct opposite the hole already cut for the sam-

pling tube. Make sure the hole is 1” to 2” below the inlet hole

on the opposite side of the duct to allow moisture drainage

away from the detector.

If the tube is shorter than the width

of the air duct

, install the end cap into the sampling tube as

shown in

Figure 4

. Sampling tubes over 3 ft. long must be

supported at the end opposite the duct smoke detector.

2. Slide the tube into the housing bushing that meets the air flow

first. Position the tube so that the arrows point into the air flow.

3. Secure the tube flange to the housing bushing with two #6

self-tapping screws.

4. For tubes longer than the width of the air duct, the tube

should extend out of the opposite side of the duct. If there

are more than 2 holes in the section of the tube extending

out of the duct, select a different length using Table 1. Oth-

erwise, trim the end of the tube protruding through the duct

so that 1” to 2” of the tube extend outside the duct. Plug

this end with the end cap and tape closed any holes in the

protruding section of the tube. Be sure to seal the duct where

the tube protrudes.

NOTE:

The sampling tube end cap is critical to the proper opera-

tion of the duct smoke detector. The end cap is needed to create

the proper air flow to the sensor of the duct smoke detector.

Figure 4. Air duct detector sampling tube:

SAMPLING

TUBE

END CAP

AIR HOLES

ARROW

MUST FACE

INTO AIR FLOW

AIR FLOW DIRECTION

FLANGE

H0108-02

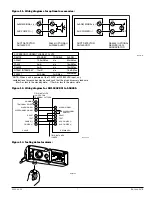

[5.4.2] Installation For Ducts More Than 8 Feet Wide

NOTE:

To install sampling tubes in ducts more than 8 feet wide,

work must be performed inside the air duct. Sampling of air in

ducts wider than 8 feet is accomplished by using the ST-10 inlet

sampling tube. If the tube is shorter than the width of the air duct,

install the end cap into the sampling tube as shown in

Figure 4

and support the end opposite the duct smoke detector.

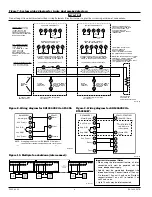

Figure 5. Tube mounting configurations with varying

air flow direction:

AIR FLOW

DIRECTION

DETECTOR

HOUSING

DOTS INDICATE POSITION OF

SAMPLING TUBE HOLES

AIR FLOW

DIRECTION

DETECTOR

HOUSING

SAMPLING

TUBE

EXHAUST

TUBE

AIR FLOW

DIRECTION

EXHAUST

TUBE

SAMPLING

TUBE

SAMPLING

TUBE

EXHAUST

TUBE

DETECTOR

HOUSING

AIR FLOW

DIRECTION

DETECTOR

HOUSING

A.

B.

C.

D.

HORIZONTAL MOUNTING OF HOUSING

VERTICAL MOUNTING OF HOUSING

NOTE: Only metal sampling tubes may be used on orientations

C and D.

WARNING

In no case should more than 2 air inlet holes be cut off the tube.

There must be a minimum of 10 holes in the tube exposed to the

air stream.

Install the inlet tube as follows:

1. Drill a

3

⁄

4

˝ hole in the duct directly opposite the hole already

drilled for the sampling tube. Make sure the hole is 1 to 2”

below the inlet hole on the opposite side of the duct to allow

for moisture drainage.

2. Slide the sampling tube with the flange into the housing bush-

ing that meets the air flow first. Position the tube so that the

arrow points into the air flow. Secure the tube flange to the

housing bushing with two #6 self-tapping screws.

3. From inside the duct, couple the other sections of the sam-

pling tube to the section already installed using the 1⁄2 inch

conduit fittings supplied. Make sure that the holes on both of

the air inlet tubes are lined up and facing into the air flow.

4. Trim the end of the tube protruding through the duct so that

1 to 2 inches of the tube extend outside the duct. Plug this

end with the end cap and tape closed any holes in the pro-

truding section of the tube. Be sure to seal the duct when the

tube protrudes.

NOTE:

An alternate method to using the ST-10 is to use two ST-5

sampling tubes. Remove the flange from one of the tubes and in-

stall as described above. After the installation, use electrical tape

to close off some of the sampling holes so that there are a total

of 10 to 12 holes spaced as evenly as possible across the width of

the duct.

NOTE:

Air currents inside the duct may cause excessive vibra-

tion, especially when the longer sampling tubes are used. In these

cases a 3” floor flange (available at most plumbing supply stores)

may be used to fasten the sampling tube to the other side of the

duct. When using the flange/connector mounting technique, drill

a 1 inch to 1

1

⁄

4

inch hole where the flange will be used.

D100-68-00

3

I56-1684-007R

H0109-01