http://air.ingersollrand.com

OPeRATIOn AnD MAInTenAnCe MAnUAL

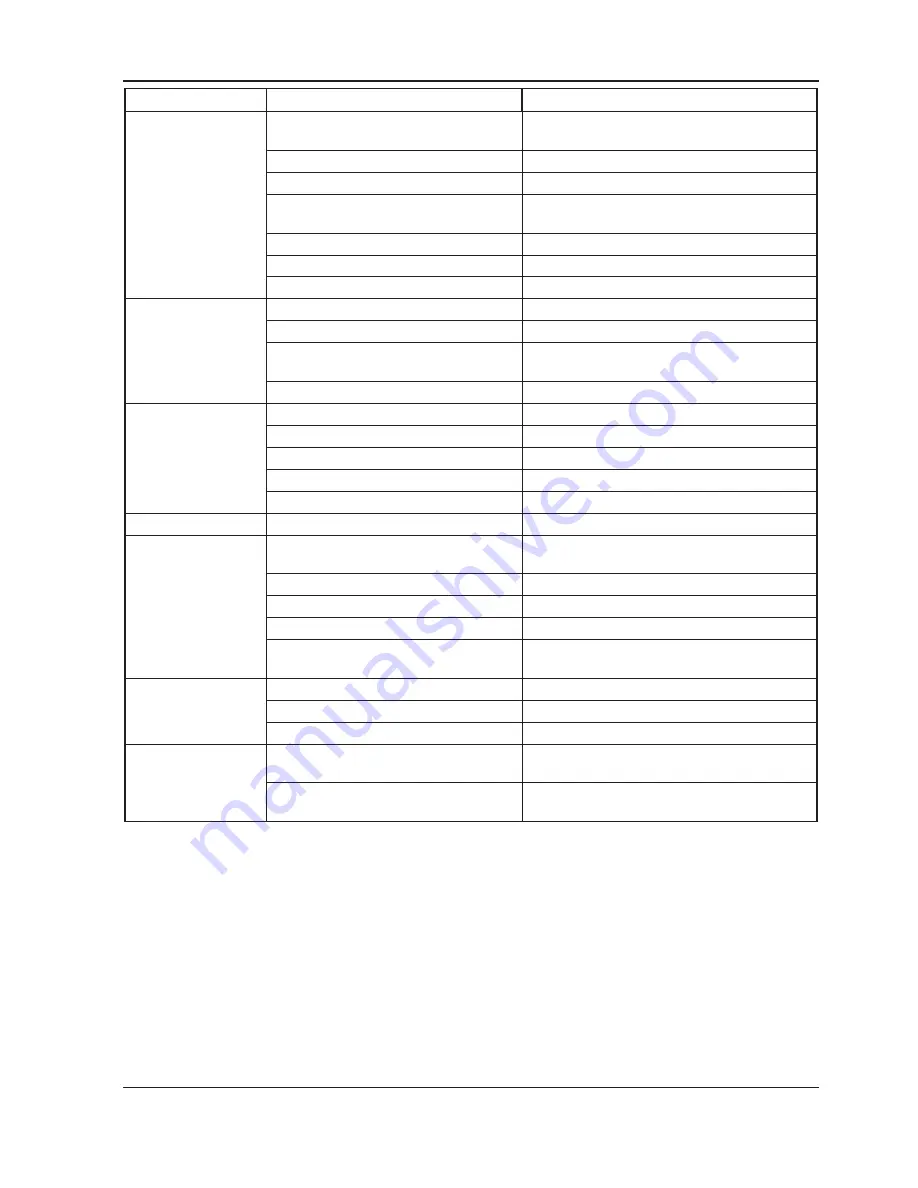

TROUBLe SHOOTInG

PROBLeM

CAUSe

ReMeDY

Compressor trips

due to over tem-

perature

Compressor operating above rated pres-

sure.

Set pressure to correct rating for machine.

Package pre–filter blocked.

Clean / replace package pre–filter.

Cooler blocked.

Clean cooler.

Missing or incorrectly fitted enclosure

panels

Ensure that all enclosure panels are correctly

fitted.

Low coolant level.

Top up coolant and check for leaks.

High ambient temperature.

Re–site compressor.

Restricted cooling air flow.

Ensure correct air flow to compressor.

excessive coolant

consumption

Separator element leak.

Fit new Separator element.

Blocked separator element drain.

† Remove fittings and clean.

Compressor operating below rated pres-

sure.

Set pressure to correct rating for machine.

Coolant system leak.

† Fix leaks.

excessive noise level

Air system leaks.

† Fix leaks.

Airend defective.

† Change Airend.

Belts Slipping.

Replace belt and tensioner.

Motor defective.

† Replace motor.

Loose components.

† Retighten loose items.

Shaft seal leaking

Defective shaft seal.

† Fit Airend shaft seal kit.

Pressure relief valve

opens

Defective switch or incorrect pressure

switch setting.

Replace or set pressure to correct rating for

machine.

Minimum pressure valve malfunction.

† Fit Minimum pressure valve service kit.

Blowdown valve defective.

† Fit blowdown solenoid service kit.

Inlet valve malfunction.

† Fit inlet valve service kit.

Pressure relief valve defective.

Check the setting of the pressure relief valve

and the rated pressure.

Black residue on belt

guard/cooler box

Drive belt slipping.

Replace belt and tensioner.

Pulleys misaligned.

Re–align pulleys.

Worn pulleys.

† Replace pulleys and belt.

Safety valve blows

when compressor

goes on load

Minimum pressure valve stuck closed.

Strip minimum pressure valve, examine and

repair if necessary.

Safety valve faulty

Check the setting of the safety valve and the

rated pressure.

nOTeS:

§ Must be carried out by a competent electrician.

† This work is recommended to be carried out only by an

Ingersoll Rand

authorized service technician.

CAUTIOn

LOW DEMAND APPLICATIONS

During periods of low demand, the compressor may not reach its normal operating temperature Sustained

operation at low demand can result in the build up of condensate in the coolant. If this situation occurs, the

lubricating characteristics of the coolant can be impaired which may lead to damage of the compressor.

THE COMPRESSOR SHOULD BE ALLOWED AMPLE LOADED RUNNING TIME OF ATLEAST 10 MINUTES PER

HOUR DURING NORMAL DAILY USE.