http://air.ingersollrand.com

2

OPeRATIOn AnD MAInTenAnCe MAnUAL

InSTALLATIOn / HAnDLInG

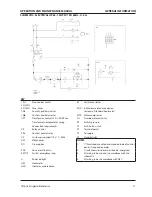

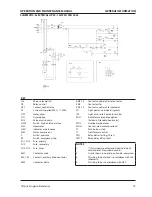

KeY

A

Package pre-filler

P

Filter, coolant

B

Hole, incoming power supply conduit

Q

Cartridge, coolant separator

C

Gauge, pressure

R

Valve, airend relief

D

Yellow stand–by light

S

Plug, coolant filler

e

Green power–on light

T

Sight–glass

F

Green start push button

U

Plug, coolant drain

G

Emergency stop button

V

Valve, pilot

H

Hourmeter

w

Switch, pressure

I

Starter box

X

Cooling air exhaust

J

Lifting points

1A

Valve, ball 0.5” N.P.T.

K

Mounting holes ( x 1.5mm [0.”] x .5mm

[1.5”] slots)

1B

Air receiver (Ø 10.0mm x 1.0mm LG) ( Ø 2.02”

x .” LG)

L

Filter, air inlet

1C

Location for manual receiver drain

M

Motor

1D

Valve, receiver relief

n

Integrated dryer (Optional)

1e

0.25” discharge port for optional electric drain

valve

O

Compressor and cooling air intake

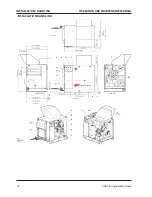

nOTeS

1. Foundation or floor must be level and support all

mounting bolt locations equally. If necessary, shim

or grout the fourth bolt location.

2. Foundation bolts should protect thru nuts a

minimum of 1mm (0.50”) to allow for levelling.

. Allow a minimum clearance of 1100mm (2”) on

the front and 20mm (”) on the top, left right

and rear of the package for proper air circulation

and serviceability.

. Approximate package weight: 55kg (1000lbs).

5. External piping shall not exert any unresolved

moments or forces on the unit. Use pipe size as

large or larger at discharge connection.

. There should be no plastic or pvc piping attached

to this unit or used for any lines downstream.

. Do not pipe into a common header with a

reciprocating compressor, unless the reciprocating

compressor utilizes a discharge pulsation damper.

. Sizing of electrical components not supplied

by

Ingersoll Rand

is the responsibility of the

customer and should be done in accordance with

the information on the compressor data plate and

national and local electrical codes.

nOTe

All dimensions are in millimetres (inches) unless

otherwise stated.

Ensure that the correct fork lift truck slots or marked

lifting points are used whenever the machine is lifted or

transported.

UnPACKInG

The compressor will normally be delivered with a

polythene cover. If a knife has to be used to remove

this cover ensure that the exterior paintwork of the

compressor is not damaged.

Ensure that all transport and packing materials are

discarded in a manner prescribed by local codes.