18-CE01D1-1F-EN

9

Accessories

Table 1. Accessories

Model Number

Description

Use with

BAYHANG

Horizontal Hanging Kit

All Upflow Furnaces

BAYVENT200B

Sidewall Vent Termination Kit

All Furnaces

BAYVENTCN200B

Sidewall Vent Termination Kit (Canada —

CPVC)

All Furnaces

BAYAIR30AVENTA

Concentric Vent Kit

All Furnaces

BAYAIR30CNVENT

Concentric Vent Kit (Canada — CPVC)

All Furnaces

BAYREDUCE

Reducing Coupling (CPVC)

All Furnaces

BAYLIFTB

Dual Return Kit (B size extension)

B Cabinet Upflow Furnaces

BAYLIFTC

Dual Return Kit (C size extension)

C Cabinet Upflow Furnaces

BAYLIFTD

Dual Return Kit (D size extension)

D Cabinet Upflow Furnaces

BAYBASE205

Downflow Subbase

All Downflow Furnaces

BAYFLTR206

Filter Access Door Kit (Downflow only)

All Upflow Furnaces

BAYSLF1165AA

(a)

1” SlimFit Box with MERV 4 Filter

All Upflow Furnaces

BAYFLTR203

Horizontal Filter Kit

B Cabinet Furnaces in Downflow/Horizontal

BAYFLTR204

Horizontal Filter Kit

C Cabinet Furnaces in Downflow/Horizontal

BAYFLTR205

Horizontal Filter Kit

D Cabinet Furnaces in Downflow/Horizontal

BAYLPSS400A

LP Conversion Kit with Stainless Steel Burners

All Furnaces

BAYMFGH200A

Manufactured/Mobile Housing Kit

All Furnaces

(a)

Airflow greater than 1600 CFM requires dual returns

Document Pack Contents

Item

Qty.

Description

S

SA

AF

FE

ET

TY

Y W

WA

AR

RN

NIIN

NG

G

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and

air-conditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered

equipment by an unqualified person could result in death or serious injury . When working on the equipment, observe all precautions in the

literature and on the tags, stickers, and labels that are attached to the equipment.

18-CE01D1-1

Upflow/Hor izontal and Downflow Gas-Fired, Direct

Vent, 2–Stag e Condensing Variable Speed Furnaces

U

Up

pffllo

ow

w ,, C

Co

on

nvve

errttiib

blle

e tto

o

H

Ho

orriizzo

on

ntta

all R

Riig

gh

htt o

orr

H

Ho

orriizzo

on

ntta

all L

Le

efftt

S9V2B040U3PSAA

S9V2B060U3PSAA

S9V2B060U4PSAA

S9V2B080U3PSAA

S9V2B080U4PSAA

S9V2C080U5PSAA

S9V2C100U4PSAA

S9V2C100U5PSAA

S9V2D120U5PSAA

D

Do

ow

w n

nffllo

ow

w O

On

nllyy

S9V2B040D3PSAA

S9V2B060D3PSAA

S9V2B080D3PSAA

S9V2B080D4PSAA

S9V2C100D4PSAA

S9V2C100D5PSAA

S9V2D120D5PSAA

N

No

otte

e:: “Graphics in this document are for representation

only . Actual model may dif fer in appearance.”

Installer’s Guide

1

1

Condensate Drain Tube Assembly

2

1

Inlet Vent

(a)

3

1

Inlet Vent Gasket

4

1

Outlet Vent Assembly

5

1

Outlet Vent Gasket

6

6

Screws

7

1

Condensate Trap Grommet

8

1

Plug — Condensate/Gas

9

1

Plug — Electrical

10

2

Grommet — Condensate/Gas

11

1

Installer’s Guide

12

1

Service Facts

13

1

Owner Guide

14

1

Limited Warranty

15

1

2” to 3” Coupling — CPL00938

(b)

(a)

3” inlet vent supplied with S9V2D120UPSBA and S9V2D120DPSBA only. 2” inlet vent supplied with all other models.

(b)

Supplied with S9V2D120U5PSBA and S9V2D120D5PSBA only

Содержание S9V2B040D3PSBA

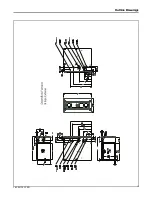

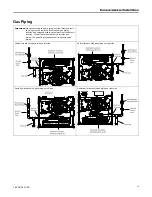

Страница 12: ...12 18 CE01D1 1F EN Outline Drawings...

Страница 13: ...18 CE01D1 1F EN 13 O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Страница 14: ...14 18 CE01D1 1F EN O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Страница 15: ...18 CE01D1 1F EN 15 O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Страница 16: ...16 18 CE01D1 1F EN O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Страница 17: ...18 CE01D1 1F EN 17 O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...