10

18-CE01D1-1F-EN

Furnace Installation Guidelines

The following sections give general guidelines for the

installation of the gas furnaces.

Safety Practices and Precautions

The following safety practices and precautions must be

followed during the installation, servicing, and

operation of this Furnace.

1. Use only with the type gas approved for this

Furnace. Refer to the Furnace rating plate.

2. Install the Furnace only in a location and position as

specified in “Locations and Clearances” of these

instructions.

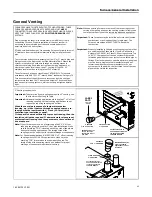

3. Provide adequate combustion and ventilation air to

the Furnace space as specified in “Air for

Combustion and Ventilation” of these instructions.

4. Combustion products must be discharged

outdoors. Connect this Furnace to an approved vent

system only, as specified in the “Venting” section

of these instructions.

5. Never test for gas leaks with an open flame. Use a

commercially available soap solution made

specifically for the detection of leaks to check all

connections, as specified in the “Gas Piping”

section of these instructions.

6. Always install the Furnace to operate within the

Furnace’s intended temperature-rise range with a

duct system which has an external static pressure

within the allowable range, as specified on the unit

rating plate. Airflow within temperature rise for cfm

versus static is shown in the Service Facts

accompanying this Furnace.

7. When a Furnace is installed so that the supply ducts

carry air circulated by the Furnace to areas outside

the space containing the Furnace, the return air

shall also be handled by a duct(s) sealed to the

Furnace casing and terminating outside the space

containing the Furnace.

8. A gas-fired Furnace for installation in a residential

garage must be installed as specified in "Location

and Clearances" section of these instructions.

9. For non-Canadian applications, the furnace may be

used for temporary heating of buildings or

structures under construction only when the

following conditions have been met:

IIm

mp

po

orrtta

an

ntt:: Gas furnaces manufactured on or after May

1, 2017 are not permitted to be used in

Canada for heating buildings or structures

under construction.

a. The Furnace venting system must be complete

and installed per manufacturer’s instructions.

b. The Furnace is controlled only by a room

Comfort Control (no field jumpers).

c. The Furnace return air duct must be complete

and sealed to the Furnace.

d. The Furnace input rate and temperature rise

must be verified to be within the nameplate

marking.

e. All air filters must be in place.

f.

100% of the Furnace combustion air

requirement must come from outside the

structure.

g. The Furnace return air temperature range is

between 55 and 80 Fahrenheit.

h. Clean the Furnace, duct work, and components

upon substantial completion of the construction

process, and verify Furnace operating

conditions including ignition, input rate,

temperature rise, and venting, according to the

manufacturer’s instructions.

10. IIn

n tth

he

e C

Co

om

mm

mo

on

nw

we

ea

alltth

h o

off M

Ma

assssa

acch

hu

usse

ettttss,, tth

hiiss

p

prro

od

du

ucctt m

mu

usstt b

be

e g

ga

ass p

piip

pe

ed

d b

by

y a

a L

Liicce

en

nsse

ed

d

P

Pllu

um

mb

be

err o

orr G

Ga

ass F

Fiitttte

err..

This Furnace is certified to leak 2% or less of nominal

air conditioning CFM delivered when pressurized to .5”

water column with all inlets, outlets, and drains sealed.

General Guidelines

The manufacturer assumes no responsibility for

equipment installed in violation of any code or

regulation.

It is recommended that Manual J of the Air

Conditioning Contractors Association (ACCA) or A.R.I.

230 be followed in estimating heating requirements.

When estimating heating requirements for installation

at Altitudes above 2000 ft., remember the gas input

must be reduced. See Combustion and Input Check.

M

Ma

atte

erriia

all iin

n tth

hiiss ssh

hiip

pm

me

en

ntt h

ha

ass b

be

ee

en

n iin

nssp

pe

ecctte

ed

d a

att tth

he

e

ffa

acctto

orry

y a

an

nd

d rre

elle

ea

asse

ed

d tto

o tth

he

e ttrra

an

nssp

po

orrtta

attiio

on

n a

ag

ge

en

nccy

y

w

wiitth

ho

ou

utt kkn

no

ow

wn

n d

da

am

ma

ag

ge

e.. IIn

nssp

pe

ecctt e

ex

xtte

erriio

orr o

off cca

arrtto

on

n

ffo

orr e

ev

viid

de

en

ncce

e o

off rro

ou

ug

gh

h h

ha

an

nd

dlliin

ng

g iin

n ssh

hiip

pm

me

en

ntt..

U

Un

np

pa

acckk cca

arre

effu

ulllly

y a

afftte

err m

mo

ov

viin

ng

g e

eq

qu

uiip

pm

me

en

ntt tto

o

a

ap

pp

prro

ox

xiim

ma

atte

e llo

occa

attiio

on

n.. IIff d

da

am

ma

ag

ge

e tto

o cco

on

ntte

en

nttss iiss

ffo

ou

un

nd

d,, rre

ep

po

orrtt tth

he

e d

da

am

ma

ag

ge

e iim

mm

me

ed

diia

atte

elly

y tto

o tth

he

e

d

de

elliiv

ve

erriin

ng

g a

ag

ge

en

nccy

y..

Codes and local utility requirements governing the

installation of gas fired equipment, wiring, plumbing,

and flue connections must be adhered to. In the

absence of local codes, the installation must conform

with latest edition of the National Fuel Gas Code ANSI

Z223.1 / NFPA 54 • National Installation Code, CAN/CGA

B149.1. The latest code may be obtained from the

American Gas Association Laboratories, 400 N. Capitol

St. NW, Washington D.C. 20001.

1-800-699-9277 or www.aga.org.

Содержание S9V2B040D3PSBA

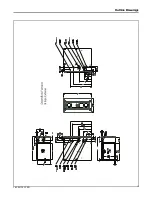

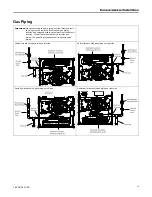

Страница 12: ...12 18 CE01D1 1F EN Outline Drawings...

Страница 13: ...18 CE01D1 1F EN 13 O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Страница 14: ...14 18 CE01D1 1F EN O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Страница 15: ...18 CE01D1 1F EN 15 O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Страница 16: ...16 18 CE01D1 1F EN O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Страница 17: ...18 CE01D1 1F EN 17 O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...