48619852_ed3

EN-22

EN

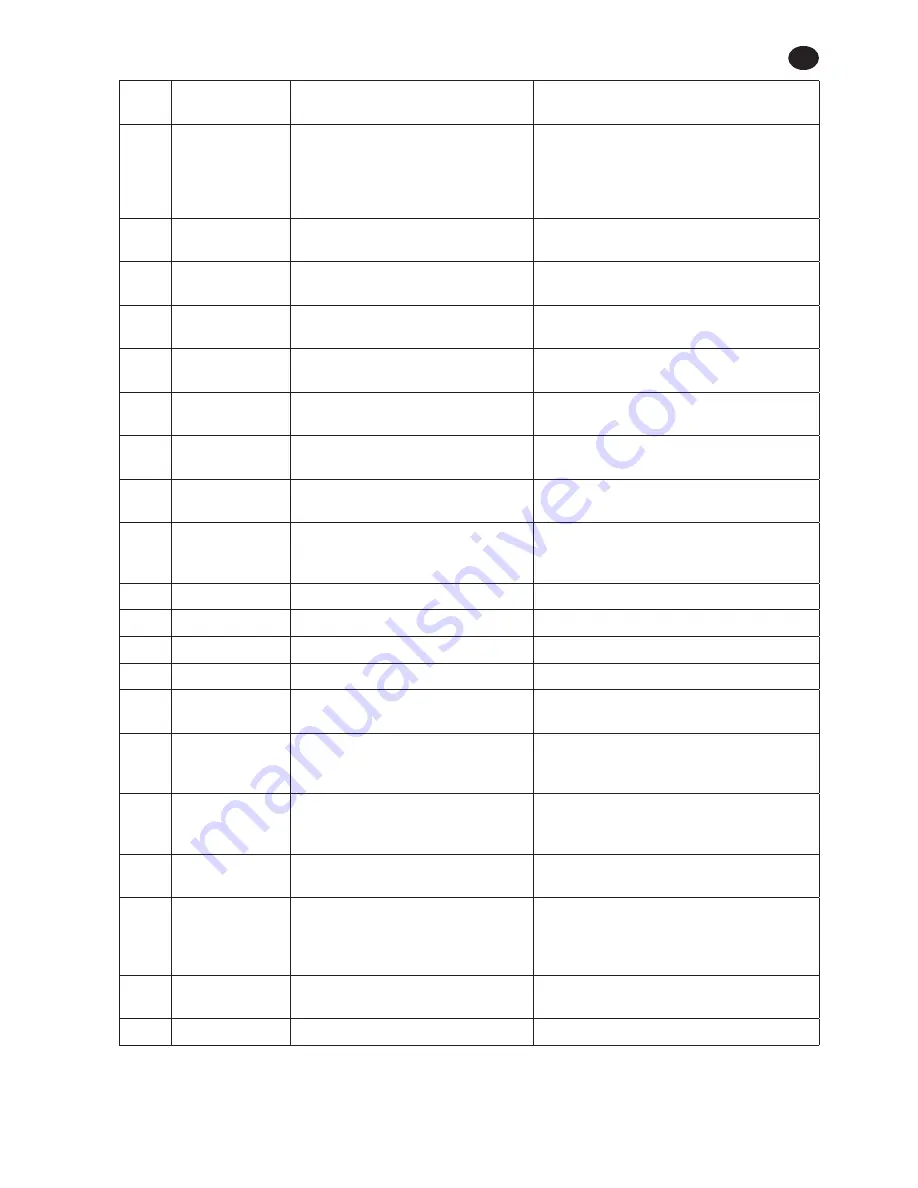

Fault

Code

Category

Notes

Actions/Solutions

E-02

Motor Controller Fault

I2T Fault.

Too much current being drawn over an extended

amount of time. Add a 10 second delay between

cycles to try and remedy. If it is a very soft joint,

try raising the shift down point so that the

majority of the cycle is run at high speed.

E-03

Motor Controller Fault

Motor Stall.

Possible damaged electronics hardware.

Contact the IR Service Center for service.

E-04

Motor Controller Fault

Motor current.

Possible damaged electronics hardware.

Contact the IR Service Center for service.

E-05

Motor Controller Fault

Over temperature.

Add a delay between cycles to allow time for

the tool to cool.

E-06

Motor Controller Fault

Current Offset.

Possible damaged electronics hardware.

Contact the IR Service Center for service.

E-0

Motor Controller Fault

Shunt Calibration.

Faulty transducer or transducer wire. Contact

the IR Service Center for service.

E-08

Motor Controller Fault

Torque Offset Fault.

Faulty transducer or transducer wire. Contact

the IR Service Center for service.

E-09

Motor Controller Fault

Transducer Fault.

Faulty transducer or transducer wire. Contact

the IR Service Center for service.

E-10

Motor Controller Fault

Under Angle.

Angle low limit is too high or the user released the

trigger before the cycle was complete. The user should

keep the trigger engaged until the cycle is complete.

E-11

Motor Controller Fault Current Plausibility Low.

Current Plausibility Low Failure.

E-12

Motor Controller Fault

Early Trigger Release.

The trigger was released before the cycle completed.

E-13

Motor Controller Fault Motor Controller Watchdog Reset.

Motor Controller Watchdog Reset.

E-14

Motor Controller Fault Motor Controller Stop Timeout.

Motor Controller Stop Timeout.

E-18

Motor Controller Fault

Multi-step configuration did not

complete due to early trigger release.

Cycle failed during one of the early stages of a prevailing

torque strategy. Retry or check the joint for problems.

E-81

Motor Controller Fault

The configuration ID in the Motor

controller’s EOR did not match the

currently selected configuration.

Configuration data in EOR does not match

currently selected configuration.

E-0A

Motor Controller Fault

Step Execution Timeout.

Check the joint for stripped threads. If the joint

is a soft joint, extend the step timeout parameter

for the fastening configuration being run.

E-0B,

E-15

Motor Controller Fault

Communication message timeouts.

Try pulling the trigger again.

E-0C

Motor Controller Fault

Over Torque limit.

Torque high limit is too low or the joint is too

hard for the fastening settings. For a hard

joint, try lowering the free speed to 0% and/

or lowering the shift down torque.

E-0D

Motor Controller Fault

Over Angle Limit.

Check the joint for stripped threads. Angle limit is too

low or the joint is too soft for the fastening settings.

E-0E

Motor Controller Fault Current Plausibility High.

Current Plausibility High Failure.

RELEASED 18/Apr/2014

Содержание QX Series

Страница 26: ...Notes RELEASED 18 Apr 2014 ...

Страница 27: ...Notes RELEASED 18 Apr 2014 ...

Страница 28: ...ingersollrandproducts com 2014 Ingersoll Rand RELEASED 18 Apr 2014 ...