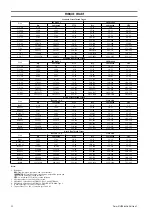

TROUBLESHOOTING

This section provides basic troubleshooting information. Determination of specific causes to problems are best identified by thorough inspections performed by

Ingersoll Rand

trained technicians. The chart below provides a brief guide to common hoist and trolley symptoms, probable causes and remedies.

SYMPTOM

CAUSE

REMEDY

Hoist will not operate.

No air supply to hoist, or too little CFM or psi. Check psi (bar) at hoist inlet. Refer to ”SPECIFICATIONS” section in Product

Information Manual for correct CFM (cu.m/min) and psi (bar).

Pendant lever sticking.

Check pendant lever and restore free movement.

Pendant malfunction.

Check psi (bar) at pendant. Minimum operating pressure in pendant line is 60

psi (4 bar).

Hoist is overloaded.

Reduce load to within rated capacity.

Motor is damaged.

Repair or replace. Refer to “MAINTENANCE” on page 5.

Limit switch sticking.

Check limit switch button moves freely. Clean and lubricate if sticking.

Brake is not releasing.

Check brake release circuit and psi (bar) at brake inlet (60 psi (4 bar) minimum).

Load continues to move when hoist is

stopped. ”UP” direction.

Pendant lever sticking.

Check lever and restore free movement.

Load continues to move when hoist is

stopped. ”DOWN” direction.

Pendant lever sticking.

Check lever and restore free movement.

Hoist is overloaded.

Reduce load to within rated capacity.

Brake is slipping.

Check brake springs and brake disc linings for wear. Refer to

“MAINTENANCE” on page 5.

Hoist will not lift rated capacity.

Hoist is overloaded.

Reduce load to within rated capacity.

No air supply to hoist or too little CFM or psi

(cu. m/min or bar).

Check psi (bar) at hoist inlet. Refer to ”SPECIFICATIONS” section in Product

Information Manual for correct CFM (cu.m/min) and psi (bar).

Brake is not releasing.

Check brake release circuit and psi (bar) at brake inlet (60 psi (4 bar) minimum).

Exhaust is restricted.

Inspect vents and clean or replace muffler.

Motor is damaged.

Check for worn motor bearings.

Hook lowers but will not raise.

Hoist is overloaded.

Reduce load to within rated capacity.

No air supply to hoist or too little CFM or psi

(cu. m/min or bar).

Check at hoist power supply connection with hoist under load. Raise pressure to

rated capacity.

Pendant malfunction.

Check psi (bar) at air inlet connection on pendant.

Load chain jumps on sprocket or is making

a snapping sound.

Worn or rusted chain.

Refer to “INSPECTION” on page 2 to determine wear limit. Replace if necessary.

Incorrect chain.

Replace with correct chain.

Worn sprocket or chain guide.

Replace worn parts.

Capsized hook.

Correct as described in “MAINTENANCE” on page 5.

Hoist not in line with load.

Align hoist with load. Do not ”yard” or ”side pull”.

Incorrectly reeved load chain.

Check load chain is correctly reeved.

No oil on load chain.

Lubricate load chain.

Trolley will not stop or trolley wheels slip. Damaged beam.

Repair or replace beam.

Excessive oil, grease or paint on track of beam. Clean off oil, grease or paint.

Trolley not spaced for beam clearance.

Check trolley spacing. Refer to the manufacturer’s literature.

Air-powered trolley does not operate.

Pendant lever sticking.

Check lever and restore free movement.

No air supply to trolley or too little CFM or psi

(cu. m/min or bar).

Check psi (bar) at trolley inlet. Refer to manufacturer’s specifications.

MAINTENANCE

WARNING

• Never perform maintenance on the hoist while it is supporting a load.

• Before performing maintenance, tag controls:

WARNING - DO NOT OPERATE EQUIPMENT BEING REPAIRED.

• Only allow Ingersoll Rand trained technicians to perform maintenance.

• After performing any maintenance on the hoist dynamically test the hoist to

100% of its rated capacity, in accordance with ASME B30.16 standards,

before returning hoist to service. Testing to more than 100% of rated

capacity is required to set overload device and may be required to comply

with standards and regulations set forth in areas outside the USA.

• Shut off air system and depressurize air lines before performing any

maintenance.

• Use of other than genuine Ingersoll Rand replacement parts may result in

safety hazards, decreased performance and increased maintenance and may

invalidate all warranties.

n

Maintenance

Personnel trained and certified by the owner/user are the only personnel authorized

to do repair or maintenance on a hoist. Correct disassembly (to prevent loss or damage

of good parts), repair, assembly, testing and adjusting are critical to proper hoist

operation. Maintenance procedures are technical in nature and require training and

experience to accomplish correctly. In addition, repair and testing require specialized

equipment that is not typically found at the hoist-mounting site.

Proper use, inspections and maintenance increase the life and usefulness of your

Ingersoll Rand

equipment. During assembly, lubricate gears, nuts, capscrews and all

machined threads with applicable lubricants. Use of antiseize compound and/or

thread lubricant on capscrew and nut threaded areas prevents corrosion and allows

for easy disassembly of components.

It is extremely important that mechanics’ and operators be familiar with the servicing

procedures of these hoists or similar products, and are physically capable of

conducting the procedures. These personnel shall have a general working knowledge

that includes:

1. Proper and safe use and application of mechanics’ common hand tools as well as

special

Ingersoll Rand

or recommended tools.

2. Safety procedures, precautions and work habits established by accepted industry

standards.

Ingersoll Rand

cannot know of, or provide all the procedures by which product

operations or repairs may be conducted and the hazards and/or results of each

method. If operation or maintenance procedures not specifically recommended by the

manufacturer are conducted, it must be ensured that product safety is not endangered

by the actions taken. If unsure of an operation or maintenance procedure or step,

personnel should place the product in a safe condition and contact supervisors and/

or the factory for technical assistance.

n

Maintenance Intervals

Refer to the ‘Maintenance Interval Chart’ on page 3 for recommended maintenance

schedule.

Form MHD56416 Edition 1

5

Содержание LCA750T

Страница 13: ...SERVICE NOTES Form MHD56416 Edition 1 13 ...

Страница 14: ...SERVICE NOTES 14 Form MHD56416 Edition 1 ...

Страница 15: ...SERVICE NOTES Form MHD56416 Edition 1 15 ...

Страница 16: ...www irtools com ...