Application Note

17 of 27

V 1.0

2021-04-30

CoolGaN™ IPS half-bridge evaluation board with IGI60F1414A1L

Setup and use

Figure 21

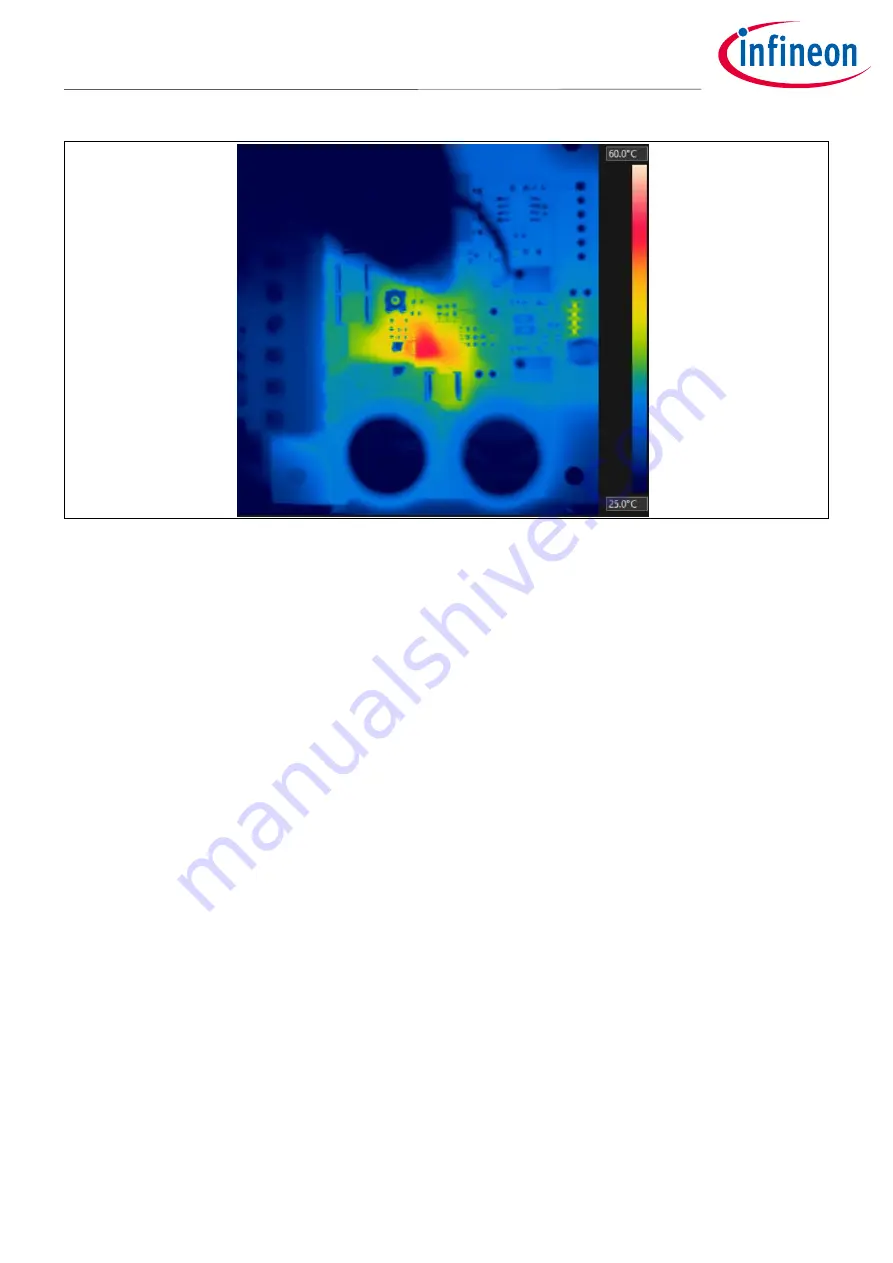

Thermal image of the chipset in soft switching condition at 200 kHz, 5 A pk-pk current

4.11

Inverter test

A full-bridge inverter can be setup using two evaluation boards configured in buck topology. The output

capacitors C20 and C12 can be used as the half-bridge inverter output filter.

configuration using the evaluation hardware. For each half-bridge, complimentary PWM signals are supplied by

a microcontroller and is connected directly to the digital input terminals (shown in

). The deadtime can

be as low as 50 ns.

shows the inverter hardware setup. The microcontroller used in this setup is

Infineon XMC1404 programmed to drive the half-bridges with Sine-PWM unipolar pattern. The generated

output line frequency is 60 Hz and the switching frequency is 65 kHz. For this test there is no closed loop control

(only open loop inverter drive with constant modulation index). The modulation index is set to have about 240

V AC output when DC bus is 380 V. The output voltage in this case is 60 Hz.

shows the load voltage and current. Each half-bridge is delivering about 72 W power (total 144 W).

The thermal image from the chipset is shown in

. Without any thermal relief the temperature of the

chipset is below 40°C. This test setup shows the benefits of using CoolGaN™ IPS half-bridge device in inverter

application in which the transistors operate in hard switching condition and a direct digital interface with a

microcontroller can save the hardware size and the BOM cost if all devices are placed in one PCB. With a very

low power dissipation, the thermal relief solution for this IPS chipset is not a challenge.