15

3-3

4

3

2

1

5

6

4

3

2

1

6

5

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

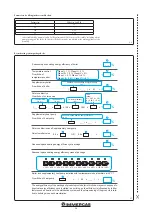

SIT 845 GAS valve

Key:

1 - Coil

2 - Minimum power adjustment

nut

3 - Maximum power adjustment

nut

4 - Gas valve outlet pressure point

5 - Gas valve inlet pressure point

6 - Protection hood

VK 4105 M GAS valve

3.5 CHECKS FOLLOWING

CONVERSION TO ANOTHER TYPE

OF GAS.

After making sure that conversion was carried

out with a nozzle of suitable diameter for the

type of gas used and the settings are made at the

correct pressure, check that:

- there is no flame in the combustion chamber;

- the burner flame is not too high or low and that

it is stable (does not detach from burner);

- the pressure testers used for calibration are

perfectly closed and there are no leaks from

the gas circuit.

N.B.:

all boiler adjustment operations must be

carried out by a qualified company (e.g. After-

Sales Technical Assistance). Burner adjustment

must be carried out using a differential “U” or

digital type manometer connected to the gas

valve outlet pressure point (part. 4 fig. 3-3),

keeping to the pressure value given in the table

(par. 3.17) according to the type of gas for which

the boiler is prepared.

3.6 POSSIBLE ADJUSTMENTS.

• Adjustment of boiler nominal thermal heat

output.

- Press the (+) key to adjust the domestic hot water

temperature (3 fig. 2-1) up to the maximum

functioning temperature.

- Open the domestic hot water cock in order to

prevent modulation intervention.

- Adjust the boiler nominal power on the brass nut

(3 Fig. 3.3), keeping to the maximum pressure

values stated in the tables (Par. 3.17) depending

on the type of gas.

- By turning in a clockwise direction the heating

potential increases and in an anti-clockwise

direction it decreases.

• Adjust the boiler minimum heat input in the

domestic hot water phase (Fig. 3-3).

N.B.:

only proceed after having calibrated the

nominal pressure.

To adjust the minimum thermal output in do-

mestic hot water phase, turn the nut (2) located

on the gas valve blocking the brass nut (3);

- disconnect the power supply to the modulating

coil (just disconnect a faston); by turning the

screw in a clockwise direction, the pressure

increases, in an anti-clockwise direction it de-

creases. On completion of calibration, re-apply

the power supply to the modulating coil. The

pressure to which the boiler minimum power

must be adjusted, must not be lower than that

stated in the tables (par. 3.17) depending on the

type of gas.

N.B.: to adjust the gas valve, remove the plastic

cap (6); after adjusting, refit the cap

.

• Adjustment of the boiler minimum heat output

in heating phase.

N.B.:

only proceed after having calibrated the

minimum domestic hot water pressure.

To adjust the minimum heat output during the

heating phase, change parameter (5), increasing

the value the pressure increases, reducing it the

pressure drops.

- The pressure to which the boiler minimum heat

output must be adjusted, must not be lower than

that stated in the tables (parag. 3.17).

3.7 PROGRAMMING THE P.C.B.

The Nike Star 24 4 ErP boiler is prepared for

possible programming of several functioning

parameters. By modifying these parameters as de-

scribed below, the boiler can be adapted according

to specific needs.

To access the programming phase (Fig. 2-1),

proceed as follows:

- press keys (1) and (2) at the same time for

approximately 15 seconds;

- Using keys (3) and (4), select the parameter to

be changed indicated in the following table:

List of

parame-

ters

Description

P0

Select solar panels

P1

Select gas type

P2

Select special G110 gas

P3

Activate anti-extruder function

P4

Activate domestic hot water post

circulation

P5

Minimum heat output

P6

Maximum heat output

P7

Heating ignitions timer

P8

Heating ramp timer

- adjust the corresponding value consulting the

table using keys (5) and (6);

- confirm the set value pressing the reset key

(1) for approximately 5 seconds; pressing keys

(3) + and (4) - at the same time to adjust the

domestic hot water temperature, the operation

is cancelled.

N.B.:

after a period of time, without touching

any keys, the operation cancels automatically.

Select solar panels

By selecting this function,

the boiler is set to be used with solar panels. By

setting the parameter P0 in “solar”on mode, the

switching off of the burner is correlated to the

adjustment of the domestic hot water tempera-

ture. In OFF mode, the burner is switched off at

the maximum value.

N.B.:

together with a solar valve kit, set the

parameter P0 in “solar”on mode (correlated).

Select solar panels

Range of values which can be set Parame-

ter

on

"solar" -

oF

(Standard settings)

P0

Select gas type

The setting of this function is used

to adjust the boiler in order to function with LPG

gas or Methane gas.

Select gas type

Range of values which can be set Parame-

ter

LG

(LPG) o

nG

(Methane) (Stan-

dard setting)

P1

Town Gas G110 –

Industrial gas. The setting of

this function is used to adjust the boiler in order

to function with gases from the first family.

Town Gas G110 - Industrial gas (first family

gas)

Range of values which can be set Parame-

ter

on

-

oF

(Standard setting)

P2

Содержание Nike Star 24 4 ErP

Страница 18: ...18 3 4 3 2 2 4 1 INSTALLER USER MAINTENANCE TECHNICIAN ...

Страница 27: ...27 ...