12

2-2

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

Key:

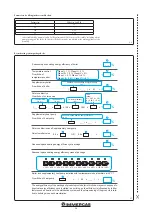

1 - Filling valve

2 - Draining valve

2.6 BOILER SHUTDOWN.

Press key (2 fig. 2-1) ( ) until the following

symbol appears ( ).

N.B.:

in these conditions the boiler is considered

still live.

Important:

if the boiler is in stand-by “

” code

error “31E” will be displayed on the Mini CRD.

The remote control is powered constantly so as

not to loose the memorised programs.

Disconnect the external omnipolar boiler switch

and close the gas cock upstream of the appliance.

Never leave the boiler switched on if left unused

for prolonged periods.

2.7 RESTORE HEATING SYSTEM

PRESSURE.

Periodically check the system water pressure.

The boiler pressure gauge should read a pressure

between 1 and 1.2 bar.

If the pressure is below 1 bar (with the circuit cool)

restore normal pressure via the cock located in the

lower part of the boiler (Fig. 2-2).

N.B.:

close the cock after the operation. If pres-

sure values reach around 3 bar the safety valve

may be activated.

In this case, remove water from an air vent valve

of a radiator until 1 bar is reached or ask for

assistance from an authorised company.

In the event of frequent pressure drops, contact

qualified staff for assistance to eliminate possible

system leakage.

2.8 SYSTEM DRAINING.

To drain the boiler, act on the special draining

valve (Fig. 2-2 e 1-8).

Before draining, ensure that the filling valve is

closed.

2.9 ANTI-FREEZE PROTECTION.

The boiler is supplied with an antifreeze function

as per standard that activates the function of the

pump and the burner when the internal system

water temperature in the boiler falls below 4°C

and stops when it exceeds 42°C. The antifreeze

function is guaranteed if the boiler is fully ope-

rative, is not in “block” status and is electrically

powered. To avoid keeping the system switched

on in case of a prolonged absence, the system

must be drained completely or antifreeze sub-

stances must be added to the heating system

water. In both cases the boiler domestic hot

water circuit must be drained. In systems that

are drained frequently, filling must be carried out

with suitably treated water to eliminate hardness

that can cause lime-scale.

2.10 CASE CLEANING.

Use damp cloths and neutral detergent to clean

the boiler casing. Never use abrasive or powder

detergents.

2.11 DECOMMISSIONING.

In the event of permanent shutdown of the boiler,

contact professional staff for the procedures and

ensure that the electrical, water and gas supply

lines are shut off and disconnected.

BOTTOM VIEW

Содержание Nike Star 24 4 ErP

Страница 18: ...18 3 4 3 2 2 4 1 INSTALLER USER MAINTENANCE TECHNICIAN ...

Страница 27: ...27 ...