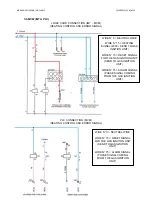

MANCANZA FIAMMA /NO FLAME

(E140901X) 21 di/of 33

MCA 1500

Gas Type

Pressure at the Nozzle

(Pout)

Nozzle Size

Air Intake Position

G20

2E e 2H

7,5

440

pos. C: 20 mm

G20

2E+

18,8

350

pos. C: 20 mm

G25

2L e 2LL

11

440

pos. D: 15 mm

G30 e GPL

3+ e 3B/P

27,7

235

pos. B: 25 mm

MCA 1800

Gas Type

Pressure at the Nozzle

(Pout)

Nozzle Size

Air Intake Position

G20

2E e 2H

8,5

440

pos. A: 30 mm

G20

2E+

18,9

365

pos. B: 25 mm

G25

2L e 2LL

12,6

440

pos. B: 25 mm

G30 e GPL

3+ e 3B/P

28,1

245

no

MCA 2100

Gas Type

Pressure at the Nozzle

(Pout)

Nozzle Size

Air Intake Position

G20

2E e 2H

7,5

480

pos. B: 25 mm

G20

2E+

18,6

380

pos. B: 25 mm

G25

2L e 2LL

11

480

pos. C: 20 mm

G30 e GPL

3+ e 3B/P

27,9

255

pos. B: 25 mm

MCM 2500/2800/3200

Gas Type

Pressure at the Nozzle

(Pout)

Nozzle Size

Air Intake Position

G20

2E e 2H

12

440

Non presente

G30 e GPL

3+ e 3B/P

27

290

Non presente

If the pressure at the outlet, while the machine is running and the heating is active, is lower than the nominal

one, do the necessary corrections by adjusting the pressure regulators outside the machine and assess the

capacity of the gas pipes from the main supply point (usually the counter) until the machine.

3.c

CHECKING THE PIPELINE’S PRESSURE DROP (LOW FLOW)

In many cases, while the machine is not working, it is possible to measure the rated pressure of the gas

supply. However, as soon as the machine tries the ignition of the burner, it is possible to appreciate a

pressure drop in which the magnitude depends from the gas plant distribution.

Too narrow or winding piping may limit the flow of gas inside the pipeline, failing to ensure the proper ignition

and combustion.

For a correct dimensioning of the gas supply pipeline must be taken in consideration the heating power of

the dryer (see the official data sheet of the dryer).

The heating power determines the real consumption of gas that is expressed in

m

3

/h

in the case of natural

gas, or in

Kg/h

in the case of liquid gas.

Consumption is declared on the data sheets, the following are the consumption

related to the “MCA” ironers

updated to September 2014 (the data may vary and are subject to change without any prior notice by IMESA

SPA).