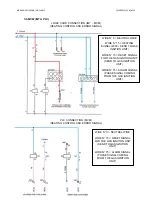

MANCANZA FIAMMA /NO FLAME

(E140901X) 23 di/of 33

Prospect A IV

– Gas volume (m

3

/h at 15°C) for liquid gas mix, density set to 1.69, stainless steel

pipelines, maximum pressure drop = 2.0 mBar

* Consider that 1 m

3

/

h

of LPG corresponds to 1.95 kg/h.

The sizing of the gas distribution system must be done by a specialist.

The above tables only serve to verify if the existing ducts facilities are sufficient to

supply the machine with the error "NO FLAME."

4.

AIR: VERIFICATION AND AIR INTAKE AND EXHAUST

The proper air intake ensures the ignition and the maintenance of the flame inside the burner. The air is

sucked from the room where the ironer is present through the fan blower, and it is conveyed to the outside

through an exhaust duct which must be suitably dimensioned and constructed in accordance with the local

law.

It thus defines PRIMARY AIR the air sucked into the burner which is mixed with the gas not yet burned.

We define SECONDARY AIR the air that comes into contact with the flame through the side windows of the

burner.

The airflow

produced by the dryer’s blower (while working at the maximum speed) is declared on the official

product’s data sheet of Imesa. Depending on the required air flow, must be dimensioned a special opening in

GAS FLOW

m

3

/h

*