16

7

、

Common problems and Solutions

7.1. Common problems and solutions are shown in the table below

phenomenon

Cause analysis

Solution

Disconnection

/ jumper

1. Too low presser foot

pressure;

2. Needle damage;

3. Incorrect position of

shuttle bed and needle。

1. Adjust the presser foot

pressure;

2. Change needle;

3. Adjust the position of

shuttle bed and needle。

Poor thread

cutting

Cutter wear

1. Sharpening fixed knife

2. Replace fixed / moving

cutter

Bad size of

edge

The position of the pull hook

is not suitable

Adjust the hook position

Nonunion of

cross

position

The upper and lower feeding

wheels are not synchronized

Adjust the upper and lower

feeding wheels to the same

speed

8

、

Daily maintenance requirements

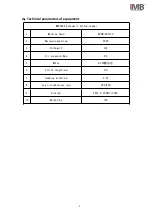

8.1. The equipment maintenance list and requirements are shown in the table below

No.

Project

Frequency

Requirement

Daily

Weekly

Monthly

Half

year

1

Clean up the

dust

√

Remove dust from equipment surface and

parts

2

Cleaning up

oil pollution

√

Clean the greasy dirt on the table ,

needle plate and bobbin

3

Air tube

interface

√

The air tube interface is tight without

air leakage

4

Oil

√

Oil volume not lower than warning line

5

Bobbin

√

Check if the bobbin is scratched

6

Slider

√

Check slide lubrication and add

lubricant if necessary

7

Electric

control box

√

Cooling fan runs normally, clean up the

dust in time

Содержание MB5004E-IM

Страница 3: ......

Страница 4: ...1 2 3 4 4 1 4 4 2 5 4 3 6 7 5 1 7 5 2 7 9 6 1 9 6 2 10 6 3 11 6 4 12 6 5 13 14 15 16 17...

Страница 5: ...1 1 GC6770 2 3 4 5 6 7 8 9 10 11 12 2 3 1 4 5 6 11 9 8 10 7 12...

Страница 7: ...3 1 1 2 V 3 4 5 6 7 8 9 10 11 12 13 14 A...

Страница 8: ...4 4 1 1 90 ON 2 3 4 MB5004E IM 1 3 4 2...

Страница 9: ...5 4 2 a b...

Страница 10: ...6 ON ON 1 2 3 ON OFF OFF 1 2 3 ON OFF 1 2 1 2 3 4 4 3 1 2...

Страница 11: ...7 5 1 5 2 5 2 1 90 ON 5 2 1...

Страница 12: ...8 5 2 3 5 2 4 90 OFF...

Страница 13: ...9 6 1 Mp 1 0 4 0 5 2 0 1 0 2 3 0 3 0 4 4 0 1 0 2 5 0 1 0 2 6 0 3 0 4...

Страница 14: ...10 6 2 6 2 1 6 2 2...

Страница 15: ...11 6 3 6 3 1 6 3 2 1 0 2mm 1 1 1 1...

Страница 16: ...12 6 4 1 2 6 4 1 1 2 6 4 2 2...

Страница 17: ...13 6 5 1 2 3 4 5 1 2 3 4 5 6 1 2 3 4 5 6 7 1 1 2 3 4 2 5 3 6 7 6 60 1 2 3 4 6 4 1 2 2 1 3 3 2 1 3 4 5 6 7 2 1 3...

Страница 20: ...16 11 1 11 2 GC6770 C 1 2 3 4 5 6 7...

Страница 21: ...17 MB5004E...

Страница 22: ...ENGLISH...

Страница 29: ...6 4 2 Operator interface description a Power on interface b Main interface...