15

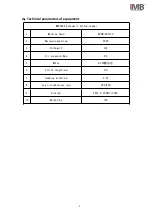

Size

Combination

Small

1+2+3+4+5

Medium

1+2+3+4+5+6

Large

1+2+3+4+5+6+7

Explain:

(

1

)

No.1. No. 2, No. 3 and No. 4 stretch fabric group are stretched by the air cylinder before sewing and

tightened after sewing

(

2

)、

No. 5 is the feeder wheel, and its position is fixed

。

(

3

)、

6 and 7 can be adjusted on the slide rail at the same time

(

Method: loosen the nut to adjust

),

And 6 can be adjusted within 60 ° around the axis point

(

Method: loosen the axis point and its left and

right screws to adjust

)。

Summary

:

According to the specific trouser leg, which kind of driving wheel combination can be

selected by trial,For example: 1, 2, 3 and 4 in the tightened state,Put the trouser leg

on the stretch fabric group,The touch screen turns off automatic sewing,Step on the pedal,

At this time, the stretch fabric group is opened。Then you can observe if the trouser legs

are tight,If it is tight, it will work properly;If it's not tight,Then you need to add

No. 6 drive wheel,It is still based on whether it can be tightened;And so on......

Additional notes:

Block , Sidewall 1, Sidewall 2,limited plate, It's used to limit the the leg. For position

requirements, see "adjustment of hemming width"

Adjustment method:

1、Block:Loosen the two set screws to adjust its position

2、Sidewall 1: Loosen the screw 1 to adjust its position

3、Sidewall 2: Loosen the screw 3 to adjust its position

Содержание MB5004E-IM

Страница 3: ......

Страница 4: ...1 2 3 4 4 1 4 4 2 5 4 3 6 7 5 1 7 5 2 7 9 6 1 9 6 2 10 6 3 11 6 4 12 6 5 13 14 15 16 17...

Страница 5: ...1 1 GC6770 2 3 4 5 6 7 8 9 10 11 12 2 3 1 4 5 6 11 9 8 10 7 12...

Страница 7: ...3 1 1 2 V 3 4 5 6 7 8 9 10 11 12 13 14 A...

Страница 8: ...4 4 1 1 90 ON 2 3 4 MB5004E IM 1 3 4 2...

Страница 9: ...5 4 2 a b...

Страница 10: ...6 ON ON 1 2 3 ON OFF OFF 1 2 3 ON OFF 1 2 1 2 3 4 4 3 1 2...

Страница 11: ...7 5 1 5 2 5 2 1 90 ON 5 2 1...

Страница 12: ...8 5 2 3 5 2 4 90 OFF...

Страница 13: ...9 6 1 Mp 1 0 4 0 5 2 0 1 0 2 3 0 3 0 4 4 0 1 0 2 5 0 1 0 2 6 0 3 0 4...

Страница 14: ...10 6 2 6 2 1 6 2 2...

Страница 15: ...11 6 3 6 3 1 6 3 2 1 0 2mm 1 1 1 1...

Страница 16: ...12 6 4 1 2 6 4 1 1 2 6 4 2 2...

Страница 17: ...13 6 5 1 2 3 4 5 1 2 3 4 5 6 1 2 3 4 5 6 7 1 1 2 3 4 2 5 3 6 7 6 60 1 2 3 4 6 4 1 2 2 1 3 3 2 1 3 4 5 6 7 2 1 3...

Страница 20: ...16 11 1 11 2 GC6770 C 1 2 3 4 5 6 7...

Страница 21: ...17 MB5004E...

Страница 22: ...ENGLISH...

Страница 29: ...6 4 2 Operator interface description a Power on interface b Main interface...