8

9

Safety instructions

For your protection

Read the operating instructions in full before st-

arting up and follow the safety instructions.

•

Keep the operating instructions in a place where they can be

accessed by everyone.

•

Ensure that only trained staff work with the appliance.

•

Follow the safety instructions, guidelines, occupational health

and safety and accident prevention regulations.

Work with the device

DANGER

Before use, check the outlet pres-

sure on the pressure reducer and

compare it with the pressure dis-

played on the pressure gauge.

Oxygen as a compressed gas is

oxidising; intensively aids combus-

tion; can react violently with flam-

mable materials.

•

The filling time should not be set to less than 30 seconds.

This will prevent combustible substances from being whirled

around in the crucible.

•

Insufficient ventilation can cause formation of explosive mix-

tures. Therefore, only use the device in well-ventilated areas.

•

Check the seals for damage before each use.

•

After finishing work, the oxygen supply on the pressure redu-

cer must be closed.

For protection of the device

DANGER

Maintenance tasks should be per-

formed without any excess pres-

sure on the system.

The Valve needle (29) is held in

place with safety varnish to keep it

from being turned unintentionally.

It should only be removed if there

iv no excess pressure on the sys-

tem

•

Keep lines and fittings through which oxygen flows free of

grease.

Unpacking

Correct use and description of the device

Use

The

IKA

C 48 oxygen filling station is only suitable for filling de-

composition vessels C 7010, C 7012 and AOD 1.1 with oxygen.

Unpacking

•

Please unpack the device carefully.

•

In the case of any damage a detailed report must be sent

immediately (post, rail or forwarder).

Delivery scope

•

C 48 oxygen filling station

•

Holding plate

•

O-rings

•

Pressure hose (2 m)

•

Operating instruction

Description of the device

•

The 2 m pressure hose, included with delivery, can easily be

laid to connect to the oxygen bottle.

•

Therefore, the location of the C 48 filling station does not

depend on the oxygen bottle being in the immediate vicinity.

•

The filling pressure that is set and the pressure in the decom-

position vessel can be read directly from the work station,

thus preventing insufficient filling quantities because of not

observing the minimum filling period.

•

The filling time can be adjusted in increments.

•

There is no need to bee constantly occupied with the oxygen

bottle because the automatic non-return valve only opens if a

decomposition vessel is being filled.

•

A carrier plate (screws on left-handed or right-handed) is

used to prepare samples.

Installation

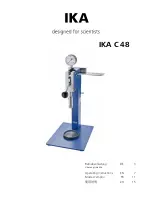

Connecting the pressure hose

The pressure hose (43), included with delivery, is designed for a

maximum pressure of 40 bar. It is 2 m long and easily be laid to

connect to the oxygen bottle (smallest permissible bending radius

80 mm).

There is an R1/4inch threading

(SW 17) on the C 29 reducing

valve (accessory) of the oxygen

bottle to which the other end of

the pressure hose can be connec-

ted.

An appropriate adapter is inclu-

ded for US pressure reducers.

Decomposition vessels

IKA

decomposition vessels C 1/8; C 7010, C 7011, C 7012 and

AOD 1.1 are provided with an identification on the base or on the

cap screw that contains information including the year of manu-

facturing number.

Assembly of the support plate

The support plate, included with

delivery, can be screwed on right

or left. The cover of the decom-

position vessel can be set down

on the support plate. This makes

it easer to load cecomposition

vessels.

C 29

It should be connected at point

“

A (SW 10)“.

Longer plastic lines are available

on request.

A

43

(SW 10)

C 29

(SW 17)

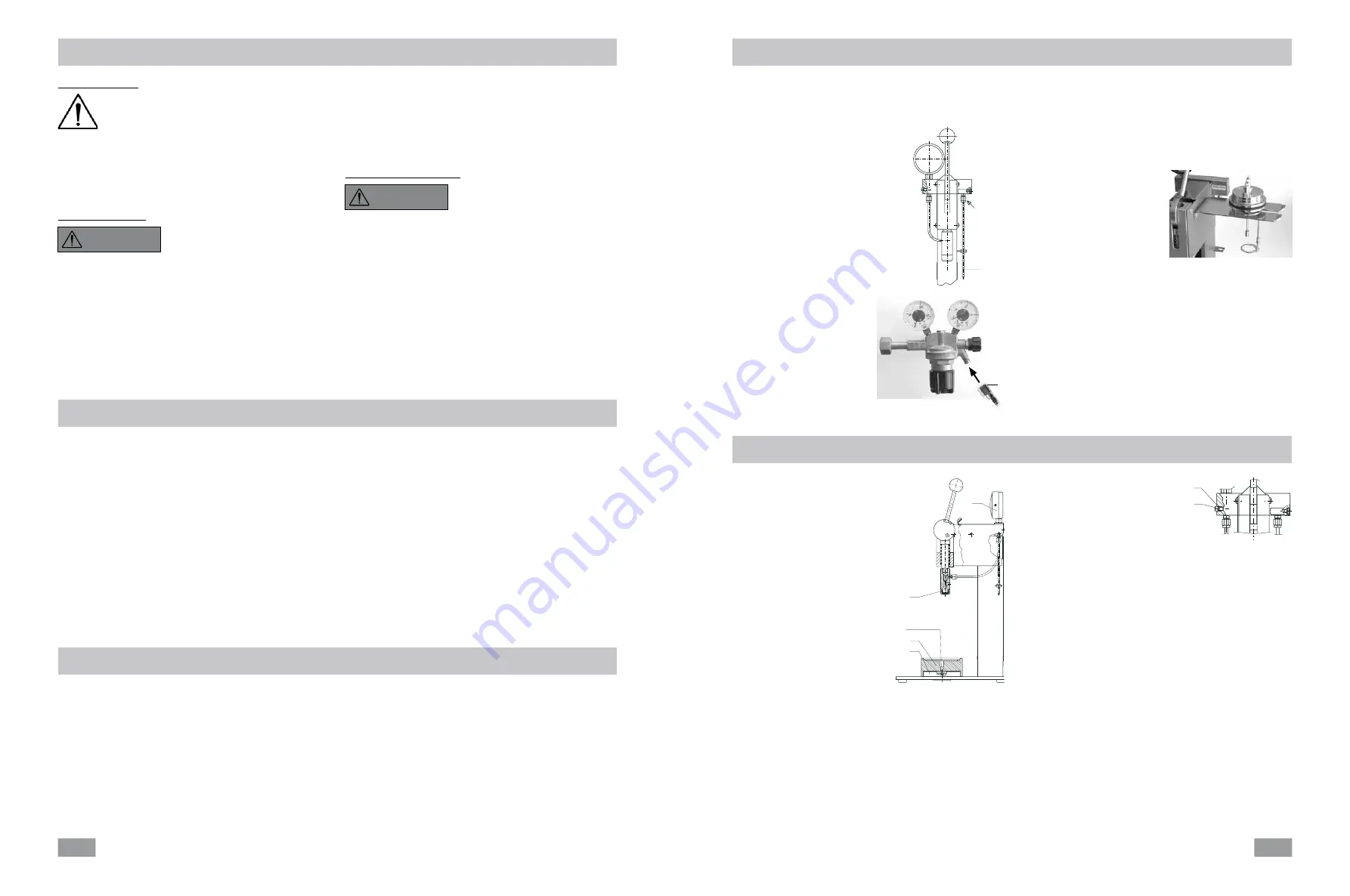

Commissioning

The required filling pressure -usually

30 bar -can be set on the pressure

reducer valve of the oxygen bottle.

The adjusted pressure can also be

read on the pressure gauge (11).

The automatic non-return valve (33)

integrated into the oxygen filling sta-

tion prevents oxygen from flowing

out when this is not intended.

When the task is complete. the

main valve on the oxygen supply

should be closed.

The decomposition vessel should be

placed on the holding plate (38 or

50). By loosening the screw (3), the

holding plate (38 or 50) can be ad-

justed so that the filling head (32) fits

exactly onto the oxygen line valve of

the decomposition vessel.

All you need to do then to fill up the

decomposition vessel is to swing the

hand lever downwards. The increase

in pressure can be observed on the

pressure gauge.

38

3

50

32

11

22

29

The factory-set filling time can be

changed by turning on the valve

needle (29). Turning the safety valve

counter-clockwise results in a longer

filling time.

The filling time should not be less than 30 seconds. This

will prevent combustible substances from being whiled

around in the crucible.

The valve needle (29) is held in place with safety varnish

to keep it from being turned unintentionally. It should only

turned if there is no excess pressure on the system.