-5-

www.igmtools.com

people and animals. Make sure you know what type of wood dust you will

be exposed to in case there is a possibility of an allergic reaction.

Wear respirator.

Fine dust that is too small to be caught in the filter will

be blown into the ambient air during operation. Always wear a NIOSH-

approved respirator during operation and for a short time after to reduce

your risk of permanent respiratory damage.

Emptying dust.

When emptying dust from the collection container, wear a

respirator and safety glasses. Empty dust away from ignition sources and

into an approved container.

Disconnecting power supply.

Turn the switch off, disconnect the

dust collector from the power supply, and allow the impeller to come to

a complete stop before leaving the machine unattended or doing any

service, cleaning, maintenance, or adjustments.

Suspended dust particles and ignition sources.

Do not operate the

dust collector in areas were explosion risks are high. Areas of high risk

include, but are not limited to, areas near pilot lights, open flames, or other

ignition sources.

Fire suppression.

Only operate the dust collector in locations that contain

a fire suppression system or have a fire extinguisher nearby.

Impeller hazards.

Do not place your hands or tools near the open inlet

during operation for any reason. The powerful suction could easily cause

accidental contact with the impeller, which will cause serious personal

injury or damage to the machine. Always keep small animals and children

away from open dust collection inlets.

Avoiding sparks.

Do not allow steel or rocks to strike the impeller—this

may produce sparks. Sparks can smolder in wood dust for a long time

before a fire is detected. If you accidentally cut Into wood containing tramp

metal (nails, staples, spikes, etc.), immediately turn off the dust collector,

disconnect it from power, and wait for the impeller to stop—then empty the

collection container into an approved airtight metal container.

Operating location.

To reduce respiratory exposure to fine dust, locate

permanently installed dust collectors away from the working area, or in

another room that is equipped with a smoke detector. Do not operate the

dust collector in rainy or wet locations—exposure to water may create a

shock hazard or decrease the life of the machine.

Static electricity.

Plastic dust lines generate high amounts of static

electricity as dust chips pass through them. Although rare, sparks caused

by static electricity can cause explosions or fire. To reduce this risk, make

sure all dust lines are thoroughly grounded by using a grounding wire.

Regular cleaning.

Regularly check/empty the collection bags or drum to

avoid the buildup of fine dust that can increase the risk of fire. Make sure

to regularly clean the surrounding area where the machine is operated—

excessive dust buildup on overhead lights, heaters, electrical panels, or

other heat sources will increase the risk of fire.

Warning: If precautions are not heeded, it may result in minor injury and/or

possible machine damage.

Warning: If precautions are not heeded, it may result in serious injury or

possibly even death.

SAVE THESE INSTRUCTIONS.

Refer to them often and use them to instruct others.

3.4 Motor Specifications

Your machine is wired for 400 volts, 50 HZ alternating current. Before

connecting the machine to the power source, make sure the switch is in

the “OFF” position.

3.5 Grounding Instructions

DANGER: THIS MACHINE MUST BE GROUNDED WHILE IN USE TO

PROTECT THE OPERATOR FROM ELECTRIC SHOCK.

1. This appliance must be connected to a grounded metal, permanent

wiring system; or an equipment-grounding conductor must be run with the

circuit conductors and connected to the equipment-grounding terminal or

lead on the appliance.

The installer, such as a qualified electrician, cut (or bend over) and

insulate the grounding conductor from a field wiring supply cable.

In the event of certain types of malfunctions or breakdowns, grounding

provides a path of least resistance for electric current—in order to reduce

the risk of electric shock.

Improper connection of the equipment-grounding wire can result in a

risk of electric shock. The wire with green insulation (with or without

yellow stripes) is the equipment-grounding wire. If repair or replacement

of the power cord or plug is necessary, do not connect the equipment-

grounding wire to a live (current carrying) terminal. Check with a qualified

electrician or service personnel if you do not understand these grounding

requirements, or if you are in doubt about whether the tool is properly

grounded. If you ever notice that a cord or plug is damaged or worn,

disconnect it from power, and immediately replace it with a new one.

Full Load Amperage

Amp draw at 230V (prewired) 17 A

Electrical Circuit Requirements

You should use a separate electrical circuit for the Laguna CFlux. The

circuit should be protected by a 16A circuit breaker with a tripping

characteristic C (16/3 / C). The power cable of the machine is factory

fitted with 400V industrial plug. The machine must be connected to an

appropriate industrial socket or the machine can be connected to a

terminal board and the wiring corresponding to the recommended fuse.

ATTENTION! WIRING MAY BE CARRIED OUT BY A QUALIFIED

ELECTRICIAN ONLY.

Recommended circuit breaker: 16A (16/3/C), tripping characteristic C.

WARNING: MAKE SURE THE SOCKET IS EARTHED. IF YOU ARE

NOT SURE, HAVE THE SOCKET CHECKED BY A QUALIFIED

ELECTRICIAN.

4. Parts Description

4.1 Functional Description

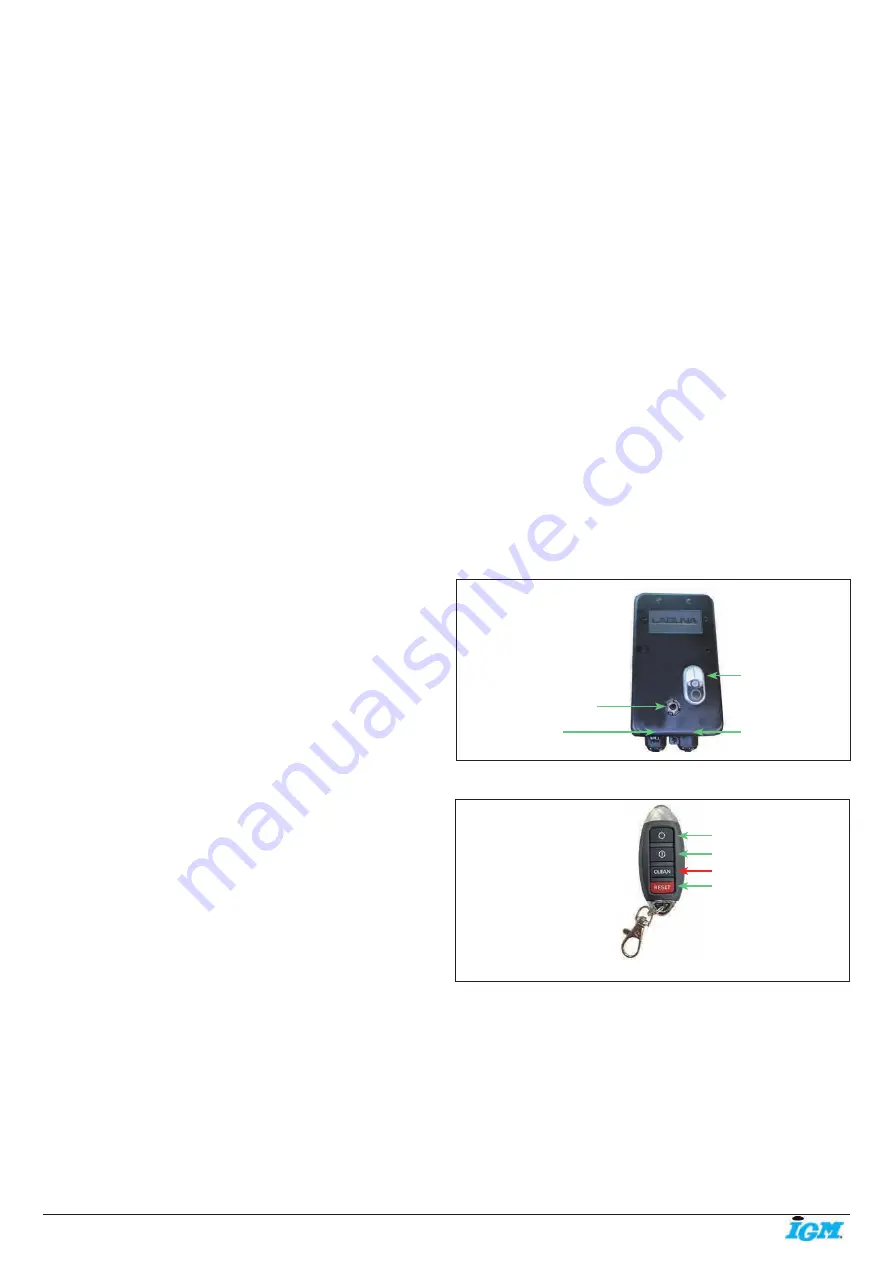

High frequency remote control switch

Hand held remote controller

PROGRAMMING THE REMOTE CONTROL

1. Ensure the machine is ON before programming the remote control.

2. Press the BLACK set button on the bottom of the remote switch until

you hear two beeps.

3. Press the Remote set button on your hand held controller

simultaneously with the BLACK button until you hear three beeps to

complete the set up.

On board circuit breaker

Power

Cord

ON/OFF

Switch

Motor Cord

ON button

OFF button

Remote set button*

CLEAN button (only for PFlux)

*Used to match up a new hand held

controller with the remote switch

Содержание Laguna CFlux3Tv2

Страница 14: ...14 www igmtools com 9 Parts breakdown Exploded Views...

Страница 15: ...15 www igmtools com 9 1 SECTION A Close up view...

Страница 16: ...16 www igmtools com 9 2 SECTION B Close up view...

Страница 17: ...17 www igmtools com 9 3 SECTION C Close up view 9 4 SECTION D Close up view...