iFLOW HVAC INC.

www.iflowhvac.com

18

Item

Display

Range

Default

Minimum Pump Speed

35 ~ 100 %

45 %

Used for advanced adjustment & troubleshooting only. Sets the

pump speed when a W1 heating call is received.

Minimum Blower Motor

Speed Control

10 ~ 100 %

20 %

Used for advanced adjustment & troubleshooting only. Sets the

blower motor speed when a W1 heating call is received.

Reserved

Future

Cool

Function

Maximum Pump Speed

35 ~ 100 %

80 %

Used for advanced adjustment & troubleshooting only. Sets the

pump speed when a W2 heating call is received.

Maximum Blower Motor

Speed Control

10 ~ 100 %

60 %

Used for advanced adjustment & troubleshooting only. Sets the

blower motor speed when a W2 heating call is received.

Blower ON Delay Time

10 ~ 120

Seconds

30

Seconds

Used for advanced adjustment & troubleshooting only. On a call for

heat, iFLOW delays blower motor operation until the hydronic coil

receives heat from the heat source (avoids blowing any cold air).

Blower OFF Delay Time

0 ~ 180

Seconds

90

Seconds

Used for advanced adjustment & troubleshooting only. Delays

blower motor shut off once a call for heat is completed to maximize

efficiency. iFLOW continues to circulate the blower to deliver any

residual coil heat to the home. Use this function in combination with

Setting #8 ‘Post Purge Function’ below. Set #8 to “1”

Post Purge Function

0: OFF 1: ON

1

Used for advanced adjustment & troubleshooting only. Sets

the pump to continue to run after a heat demand to maximize

efficiency by extracting all residual heat from the heat source.

iFLOW continues to circulate the pump to deliver any residual heat

to the hydronic coil, instead of the heat source post-purging its

residual waste heat through the exhaust vent. Use this function in

combination with Setting #7 ‘Blower Off Delay Time’ above.

DHW Priority

0 = ON, 1=OFF

1

Used for advanced adjustment & troubleshooting only. When a flow

switch on the cold water supply is installed and wired to the iFLOW

AHU, iFLOW offers DHW Priority. Set whether or not the air handler

should shut down during periods where there is a demand for

domestic hot water.

For cool

future

function

Heating Parameter Mode

How to access Heating Parameter:

Push the mode button until the screen reads

Press ‘ENT’ (enter) to confirm Heating Parameter Mode. Use the

‘UP’ and ‘DN’ (down) buttons to scroll through the menu of heating

parameters, numbered 01-16. The 1-3 characters on the right

indicate the value. Use the up and down buttons to change the

range of the value and press ‘ENT’ to confirm and ‘MODE’ to exit.

Item

Display

Range

Default

Smart Mode

0= OFF, 1=ON

0

There are 2 way to deliver temperature to the home: 1) Thermostat

Mode and 2) Smart Mode. Thermostat mode relies on the room

thermostat to provide a signal for the air handler to come on and

turn off. Smart Mode by-passes the room thermostat and instead

circulates air continuously through the home and relies on the return

air temperature to indicate if more or less heating/cooling required.

The ECM blower is default set at 10% but can be set as low as 5%

to minimize energy consumption. See ‘General’ parameter #11

(Continuous Circulation (‘G’ Call) Blower Speed) to adjust. WiFi

mode must be set to ‘internet’. Also use this function when zoning

but do not have a thermostat for every zone (i.e.: in a retrofit, when

you cannot run new wire).

Wi-Fi Mode

0=Internet,

1=Paring

1

There are 2 ways to connect to, and communicate with the iFLOW

Air Handler using the iFLOW App: through the internet or by pairing.

Through the internet requires the contractor or homeowner to

connect the iFLOW Air Handler to the homeowner’s local home Wi-

Fi network. Pairing connects your smartphone to the air handler

without a local network (similar to pairing a phone to a car’s stereo).

In pairing mode, the phone must be in close proximity of the iFLOW

unit.

Emergency Mode

0=OFF,

1=Heat,

2=Cool

0

Use this setting to override the thermostat and run the heating or

cooling automatically in an emergency. Provides emergency heating

or cooling should there be a thermostat failure.

Schedule Mode

0=OFF, 1=ON

0

Use this mode to select whether you want to use the iFLOW

scheduling function.

Day

1:SUN 2:MON

3:TUE 4:WED

5:THU 6:FRI

7:SAT

SUN

Set current day of the week

Time

HH:0~24,

MM:0~59

Current

Time

Set current time (24 hour clock)

Содержание iFLH-14000W

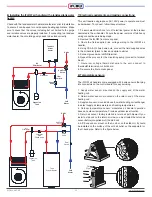

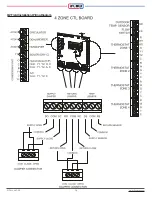

Страница 24: ...iFLOW HVAC INC www iflowhvac com SZ Field Installation Wiring Diagram 24 See Details Page 29...

Страница 26: ...iFLOW HVAC INC www iflowhvac com DZ Field Installation Wiring Diagram 26 See Details Page 29...

Страница 28: ...iFLOW HVAC INC www iflowhvac com QZ Field Installation Wiring Diagram 28...

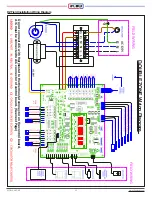

Страница 30: ...iFLOW HVAC INC www iflowhvac com 4 Ladder Diagram 30...

Страница 34: ...iFLOW HVAC INC www iflowhvac com 34 3 Component Assembly Diagram and Parts Lists Assemble Diagram...

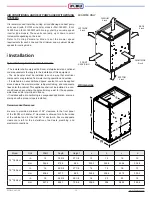

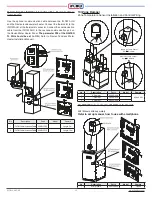

Страница 42: ...iFLOW HVAC INC www iflowhvac com 42 4 Installation Diagram iFLOW EZEE Plumbing Kit and iFLOW Stand...

Страница 43: ...iFLOW HVAC INC www iflowhvac com 43 Installation on the wall...

Страница 44: ...iFLOW HVAC INC www iflowhvac com 44...